Flexible bus and preparation method thereof

A technology of flexible busbars and wires, which is applied in the manufacture of wire harnesses, cable/conductor manufacturing, electrical connectors, etc., which can solve the problems of large installation space and small bending angle range of flexible busbars, so as to save connection space and make bending angles difficult The effect of deformation and bending angle stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

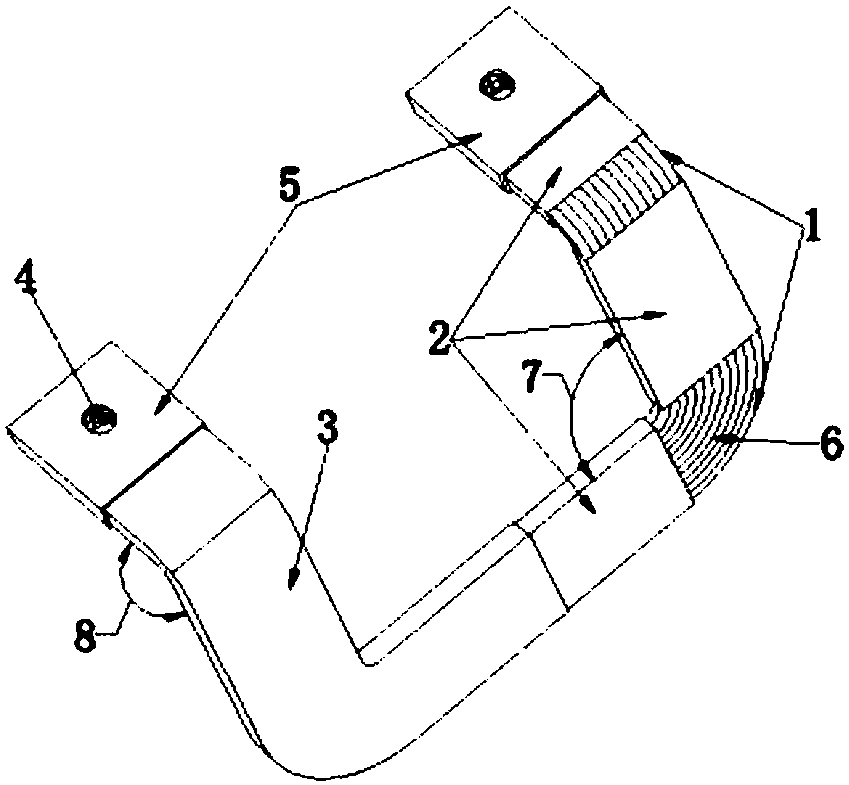

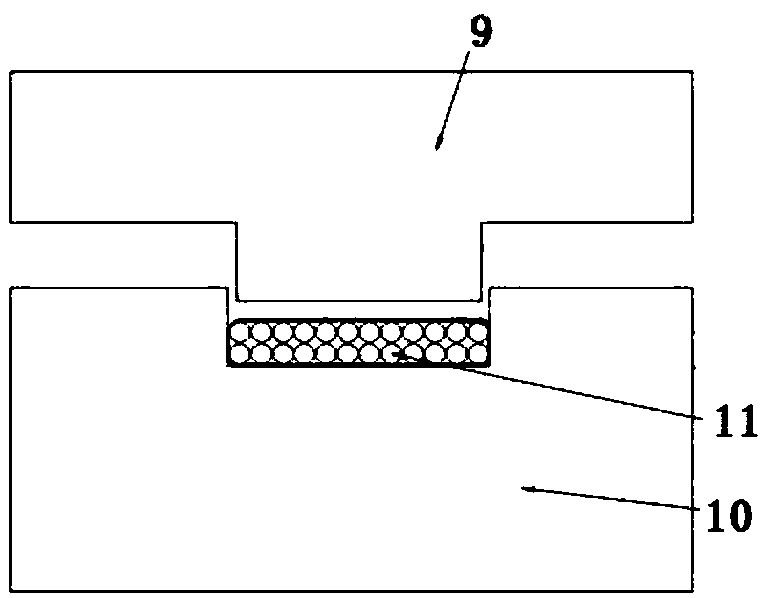

[0022] Such as figure 1 As shown, it is the flexible busbar of this embodiment, with a cross-sectional area of 70mm 2 . The soft busbar of this embodiment includes a conductor body, and the conductive body is covered with an insulating layer 3 (the insulating layer on the right half of the soft busbar is not on the figure 1 shown in ), the insulating layer is formed by dipping process. The above-mentioned conductive body is a wire bundle with an upper and lower two-layer structure, each layer structure of the wire bundle includes 12 wires 6 and the wires of each layer are arranged side by side. Each conductor is twisted by 22 T2 sub-conductor copper wires with a diameter of 0.42mm. The wire harness is provided with a bending area 1 and fixing areas 2 located on both sides of the bending area in the extending direction of the conductive body. The parts of the wires in the bending area are not fixed to each other, that is, they can move relative to each other. The part of...

Embodiment 2

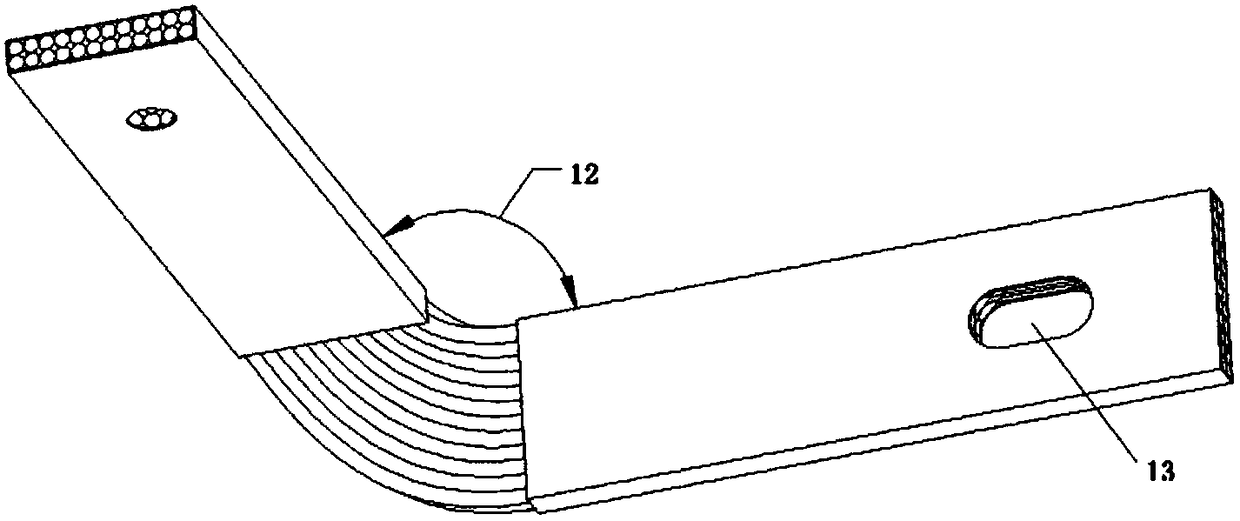

[0026] The only difference between this embodiment and Embodiment 1 is that the flexible busbar of this embodiment is only provided with one kind of bending such as image 3 As shown in middle bend 12, the bend shown in bend 12 is a twisted bend. After bending, the planes on both sides of the bend are perpendicular to each other and the extension lines of the two sides are perpendicular to each other. In this embodiment, the connecting end of the soft busbar is provided with a waist-shaped bolt hole 13 that passes through the metal connection belt and the wire harness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com