A device and method for testing pull strength of an embedded hanger

A pull-out strength and test device technology, applied in the application field of research and test development results, can solve the problems of no pre-embedded hangers, not wide enough application range, time-consuming and labor-intensive, etc., achieving a simple installation process and making up for the pull-out strength detection field The blank, flexible effect of the test site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

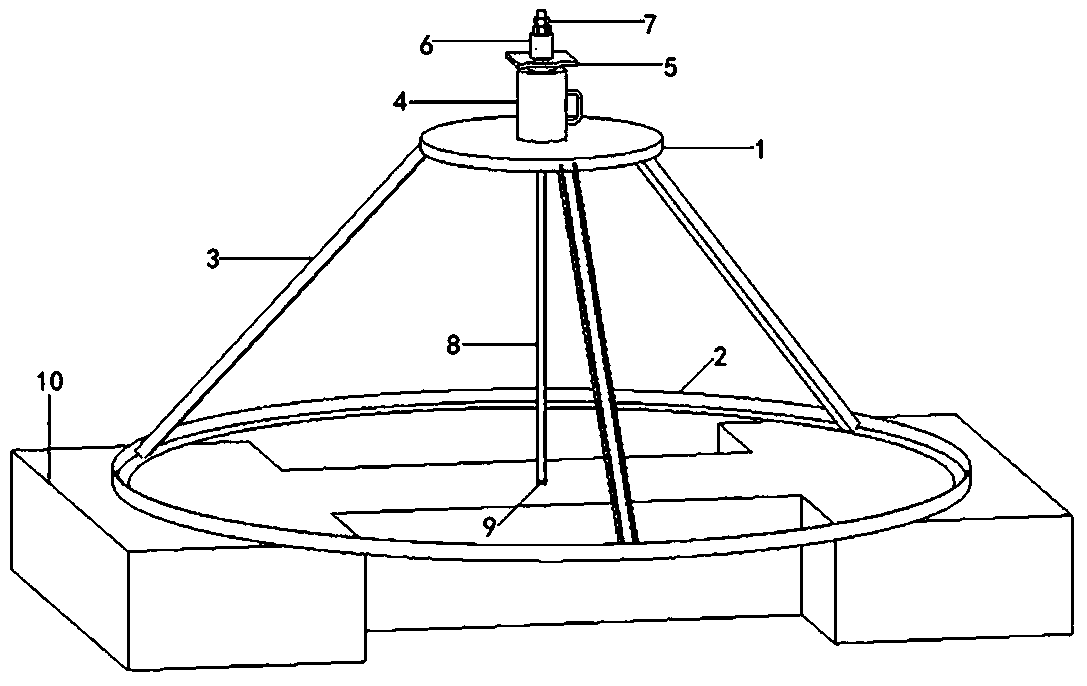

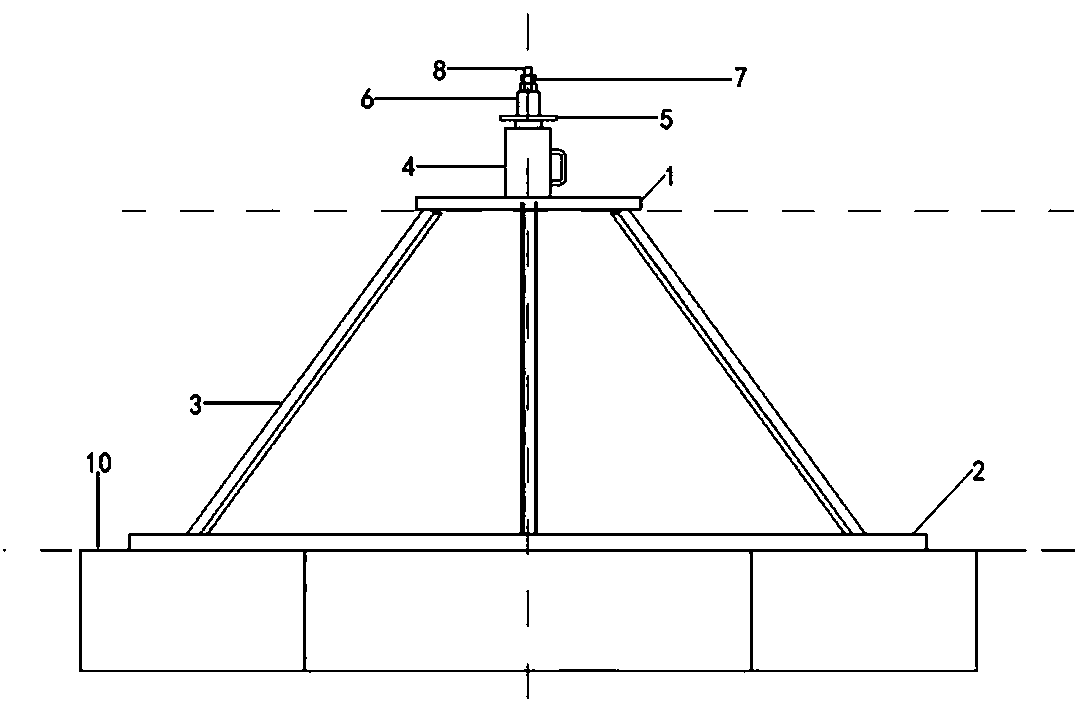

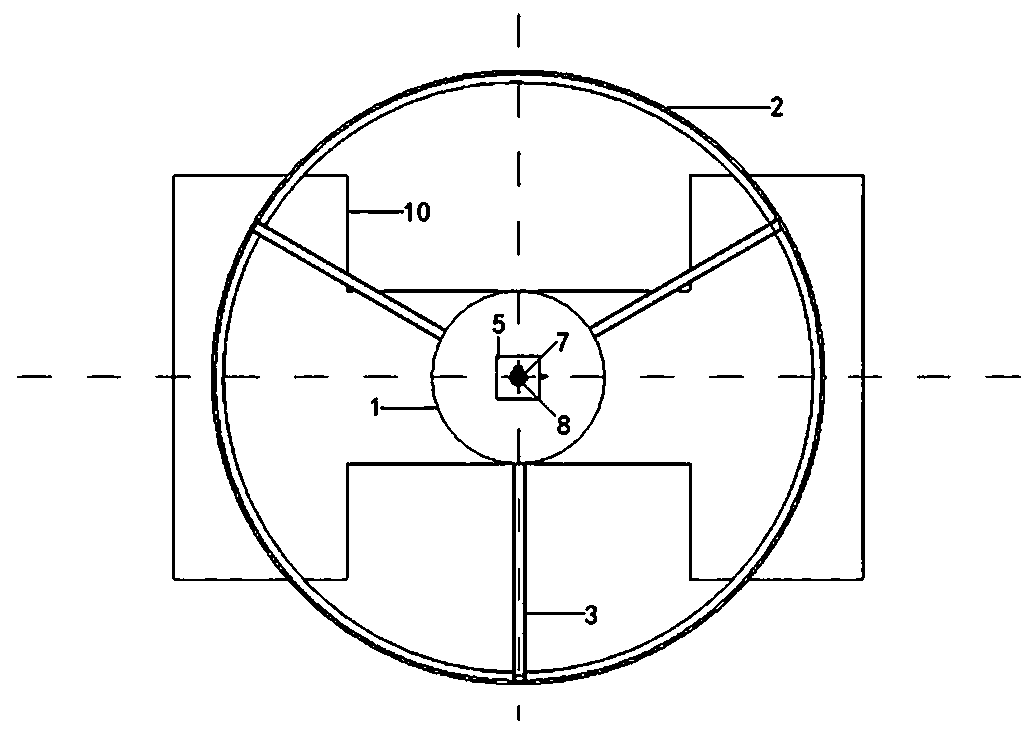

[0028] Example: such as Figure 1~6 As shown, a pre-embedded hanger pullout strength test device includes steel plate A1, circular angle steel 2, channel steel leg 3, through-hole jack 4, steel plate B5, force sensor 6, fixture 7, force transmission steel bar 8, Embedded hangers 9 and base material concrete 10;

[0029] The steel plate A1 is a circular steel plate, and the steel plate A1, the ring angle steel 2 and the channel steel leg 3 are welded into a circular platform support, and the steel plate A1 is the top of the circular platform support, and the channel steel support legs 3 are set to three, and the channel steel The included angle between the outrigger 3 and the ring angle steel 2 is 30°-45°, the included angle between the two adjacent channel steel outriggers 3 is 120°, and the circular truncated support is set on the base material concrete 10, and the base material concrete 10 is placed on the ground; the center of the steel plate A1 is provided with a round ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com