A Structure of Electric Water Pump and Water Gun with Stroke Changing Mechanism

An electric water pump with stroke technology, which is applied in the direction of machines/engines, variable capacity pump components, liquid variable capacity machines, etc., can solve the problems of large volume, limited application range of electric water pumps, and high requirements for power supply equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described below in conjunction with the drawings and embodiments.

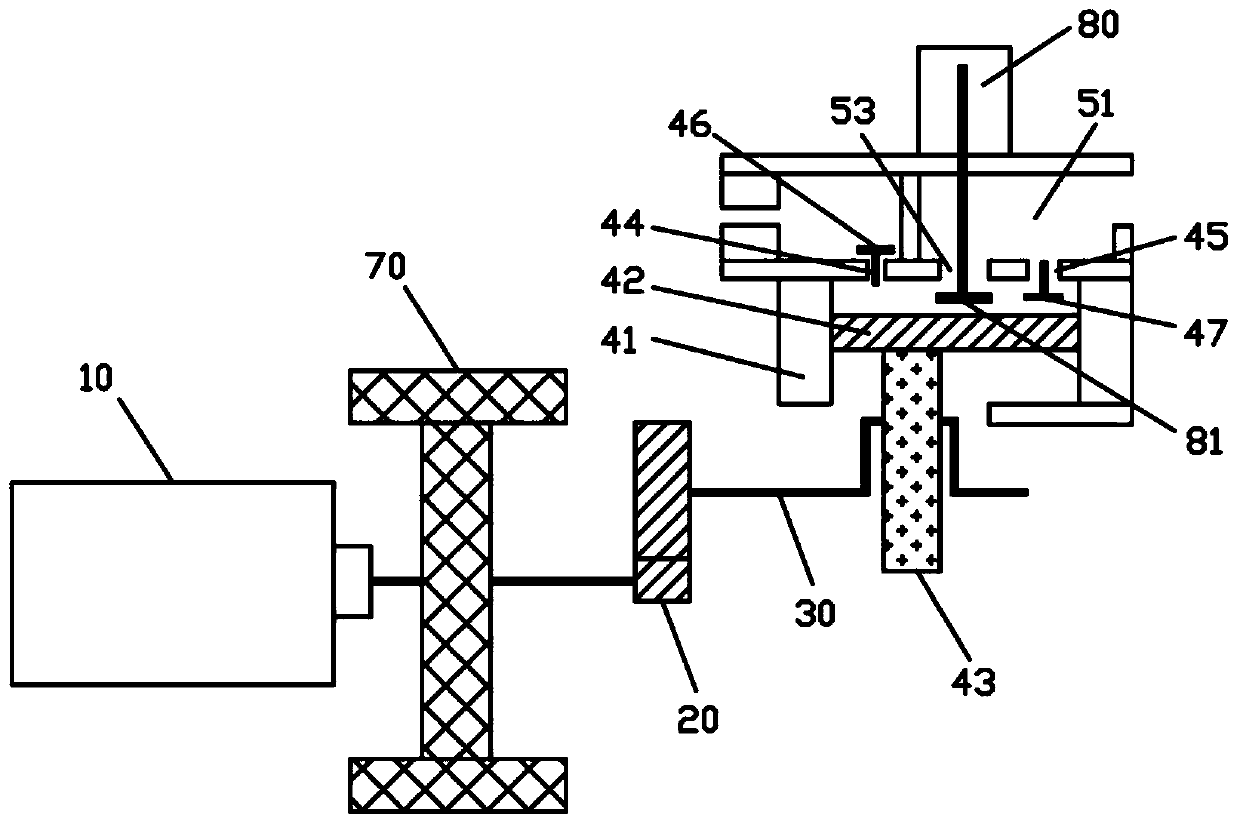

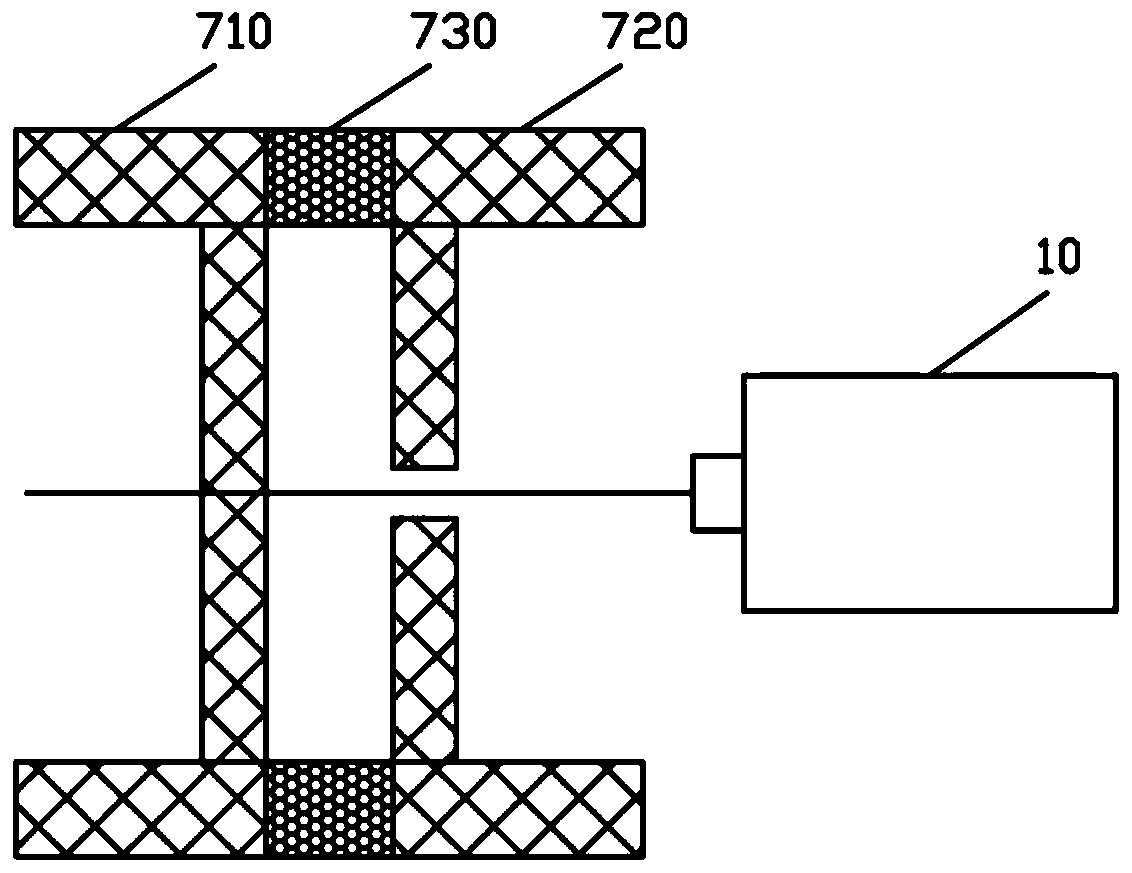

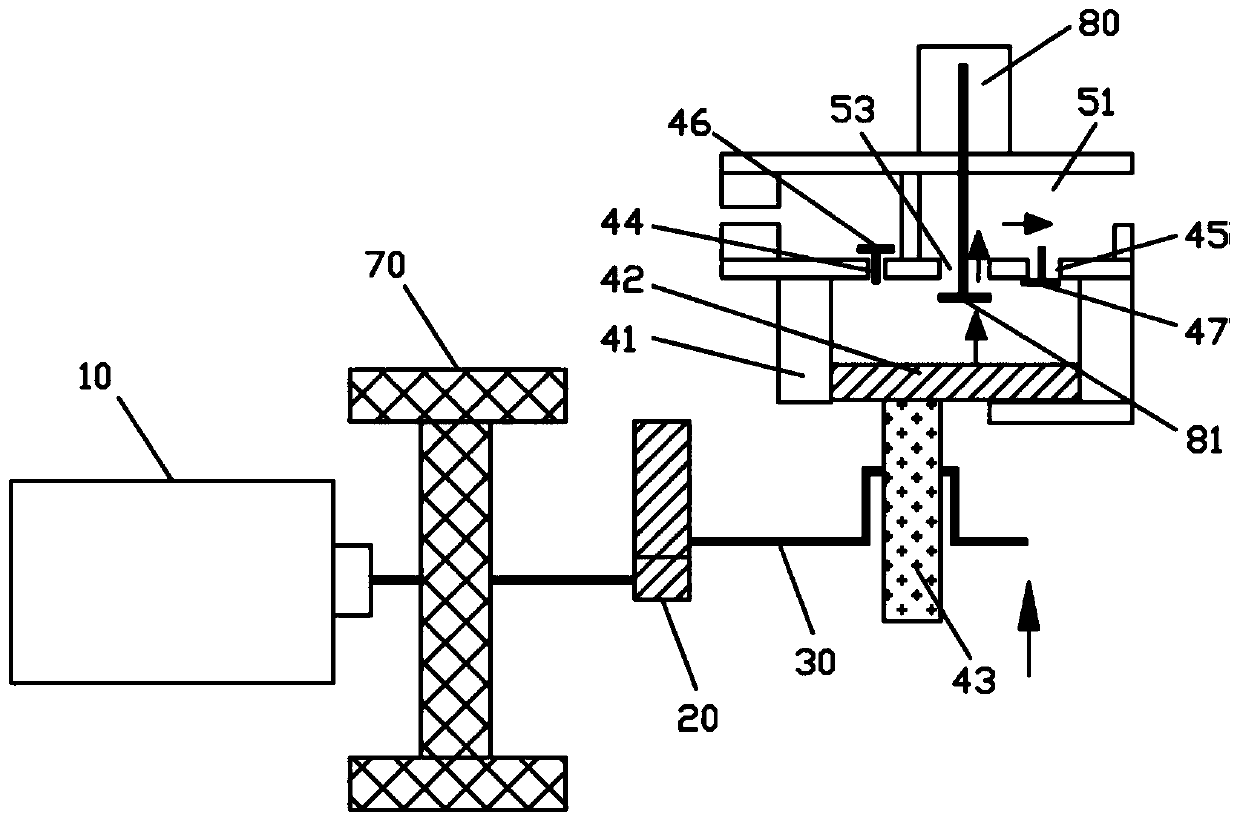

[0025] Such as figure 1 As shown, an electric water pump with a stroke changing mechanism according to the present invention includes a motor 10, a gear set 20, a transmission mechanism 30, a piston mechanism and a stroke changing mechanism, and the output shaft of the motor 10 is connected to the transmission mechanism 30 through a gear set 20. , the transmission mechanism 30 is connected to the piston mechanism (in practical applications, the piston mechanism adopts a single-piston structure), the piston mechanism includes a piston cylinder 41, the piston cylinder 41 is provided with a piston body 42, and the piston body 42 is connected to the transmission mechanism 30 through a piston rod 43 , the transmission mechanism 30 drives the piston body 42 to move up and down through the piston rod 43, the piston cylinder 41 is provided with a water ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com