Blowing valve interlock control device

A technology of chain control and air valve, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problems of cumbersome operation, high cost, complex structure, etc., achieve convenient use, simple structure, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

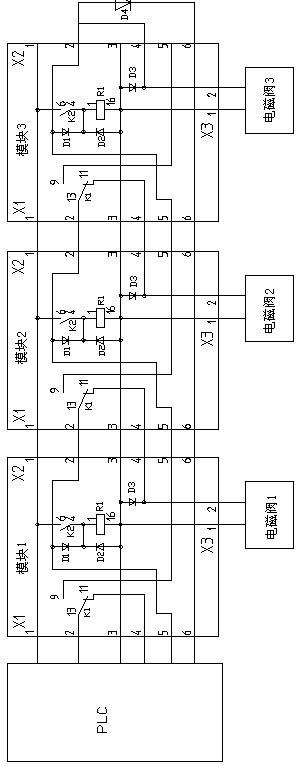

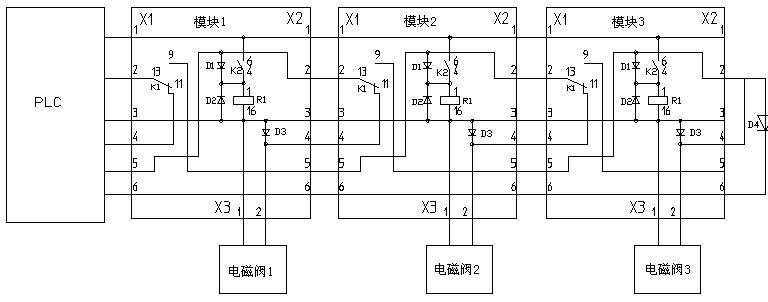

[0013] Embodiment: A blowing valve chain control device, including PLC, module group, relay module, solenoid valve and terminal plug, each relay module is connected to a solenoid valve, and the module group is formed by at least two relay modules connected in series, The PLC is connected to the head of the module group, and the terminal plug is connected to the tail of the module group to form a chain control circuit.

[0014] PLC inputs 24V signals to input port 1 and input port 5 of module 1 respectively, coil L in module 1 is energized, contacts 13 and 9 are connected, contacts 4 and 6 are connected, and self-protection; the other one is connected to the solenoid valve 1. Solenoid valve 1 is energized and opened.

[0015] Disconnect the 24V signal of the input port 5 of module 1, the solenoid valve 1 is de-energized and closed, input the 24V signal to the input port 2 of the module 1, pass through the 13 and 9 contacts of the module 1, come out from the output port 5 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com