Reaction water turbine fixed guide vane resonance and crack prevention method

A technology for fixing guide vanes and water turbines, which is applied in the field of water turbines, can solve the problems of whistling, affecting the working stability of the hydraulic turbine, and fixing guide vanes cracks, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

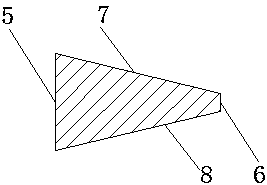

[0040] see figure 1 and figure 2 , the method for preventing cracks from resonating on fixed guide vanes of an impact turbine comprises the following steps:

[0041] a. Determine the empennage 4 according to the geometric dimensions of the section of the fixed guide vane 3 on the seat ring of the impact turbine, and process the empennage 4 for standby;

[0042] b. Reserve a distance h between the upper end of the empennage and the upper ring plate 1 , reserve a distance h between the lower end of the empennage and the lower ring plate 2 , h 1 1% of fixed guide vane height h, h 2 1% of fixed guide vane height h;

[0043] c. Install the empennage 4 on the water outlet edge of the fixed guide vane 3 .

[0044] "a. Determine the empennage according to the geometric dimensions of the fixed guide vane section on the seat ring of the impact turbine, and process the empennage for use; b. Reserve a distance h between the upper end of the empennage and the upper ring plate 1 , r...

Embodiment 2

[0046] see figure 1 and image 3 , the method for preventing cracks from resonating on fixed guide vanes of an impact turbine comprises the following steps:

[0047] a. Determine the empennage 4 according to the geometric dimensions of the section of the fixed guide vane 3 on the seat ring of the impact turbine, and process the empennage 4 for standby;

[0048] b. Reserve a distance h between the upper end of the empennage and the upper ring plate 1 , reserve a distance h between the lower end of the empennage and the lower ring plate 2 , h 1 2% of fixed guide vane height h, h 2 2% of fixed guide vane height h;

[0049] c. Install the empennage 4 on the water outlet edge of the fixed guide vane 3 .

[0050] In the step c, the empennage 4 is welded to the water outlet edge of the fixed guide vane 3 by root cleaning and penetration.

[0051] The seat ring of the impact turbine includes an upper ring plate 1, a lower ring plate 2 and a plurality of fixed guide vanes 3 fixe...

Embodiment 3

[0054] see figure 1 and image 3 , the method for preventing cracks from resonating on fixed guide vanes of an impact turbine comprises the following steps:

[0055] a. Determine the empennage 4 according to the geometric dimensions of the section of the fixed guide vane 3 on the seat ring of the impact turbine, and process the empennage 4 for standby;

[0056] b. Reserve a distance h between the upper end of the empennage and the upper ring plate 1 , reserve a distance h between the lower end of the empennage and the lower ring plate 2 , h 1 3% of fixed guide vane height h, h 2 3% of fixed guide vane height h;

[0057] c. Install the empennage 4 on the water outlet edge of the fixed guide vane 3 .

[0058] In the step c, the empennage 4 is welded to the water outlet edge of the fixed guide vane 3 by root cleaning and penetration.

[0059] The seat ring of the impact turbine includes an upper ring plate 1, a lower ring plate 2 and a plurality of fixed guide vanes 3 fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com