Steel-structured scaffold device for machinery aspect

A scaffolding and steel structure technology, applied in the field of scaffolding, can solve the problems of inconvenient overall movement, manual installation, inconvenience, etc., and achieve the effects of easy and stable mutual connection, reduced floor space, and convenient overall connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

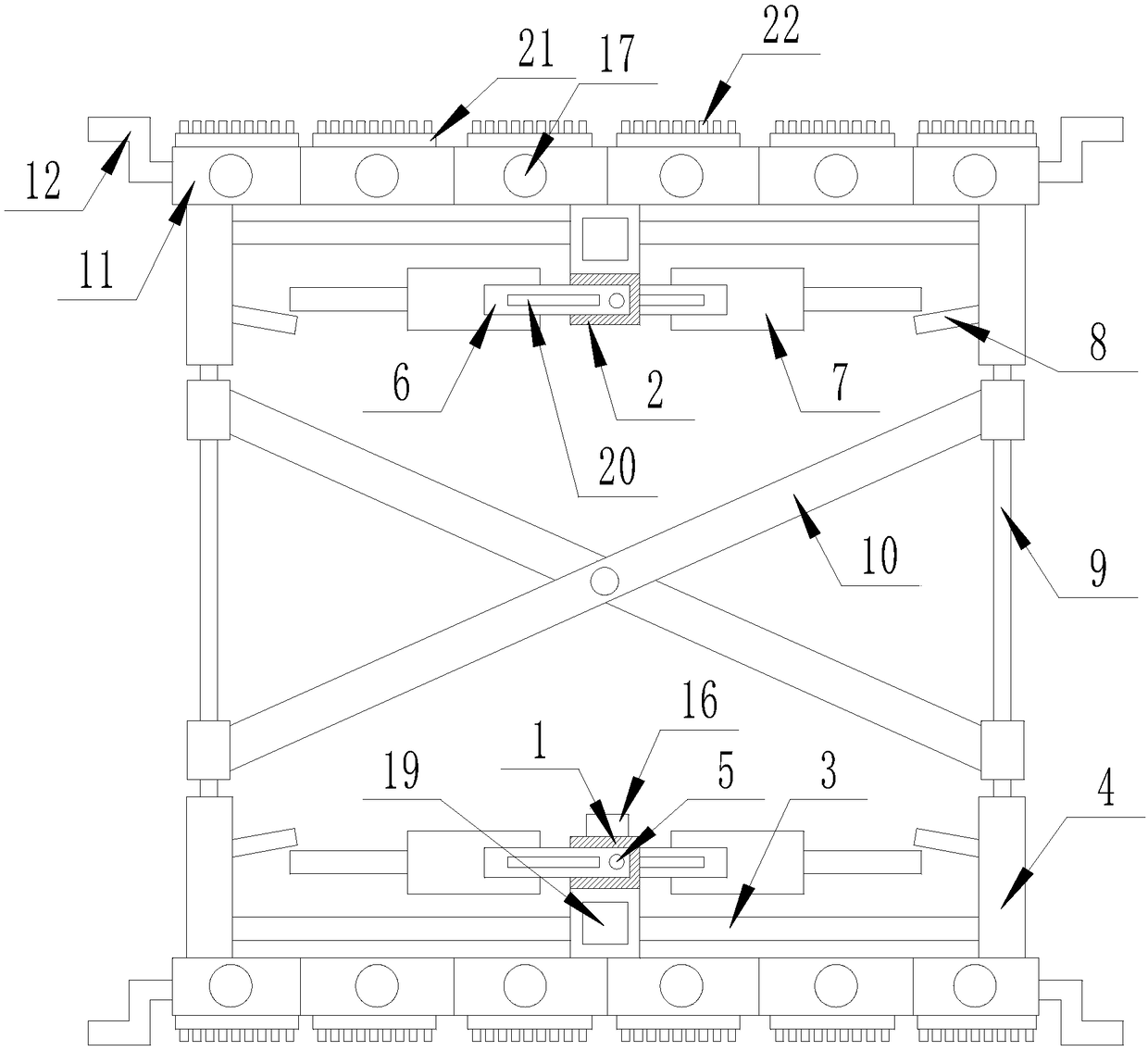

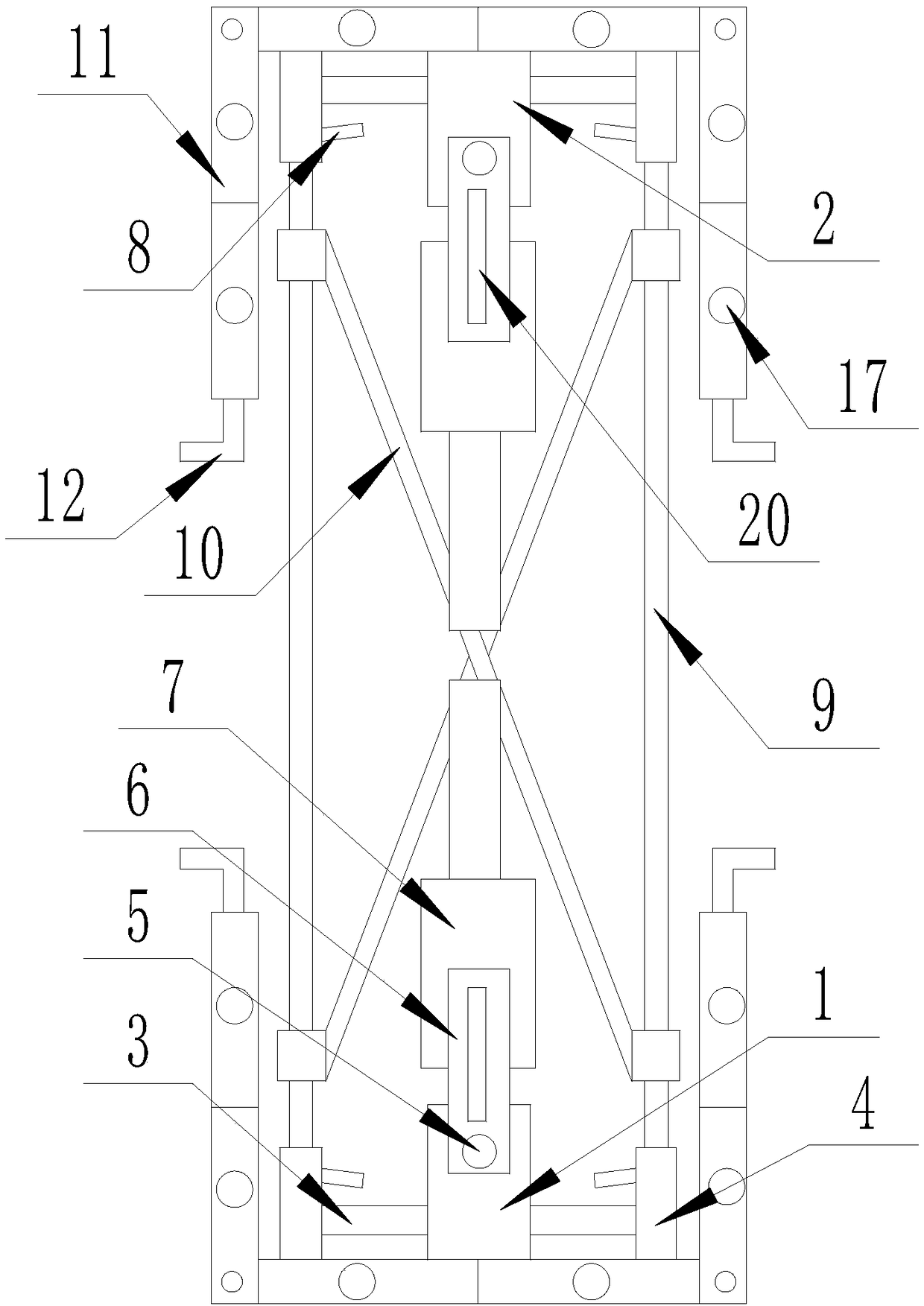

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 As shown, a steel structure scaffolding device used in machinery includes a No. 1 bar-shaped support block 1, and a No. 2 bar-shaped support block 1 matching the No. 1 bar-shaped support block 1 is arranged above the No. 1 bar-shaped support block 1. Support block 2, scaffold mechanism is established between described No. 1 bar-shaped support block 1 and No. 2 bar-shaped support block 2, and described scaffold mechanism is mainly arranged on No. 1 bar-shaped support block 1 and No. 2 bar-shaped support block 2 A number of horizontal stretch rods 3 on two opposite side surfaces, a mobile frame arranged on both sides of the No. 1 bar-shaped support block 1 and the No. 2 bar-shaped support block 2 and connected to the end faces of the corresponding several horizontal stretch rods 3 4. A number of strip-shaped through grooves processed on the No. 1 strip-shaped sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com