Intelligent automatic welding manipulator

An automatic welding and manipulator technology, applied in the field of manipulators, can solve problems such as high manufacturing and operating costs, complex overall structure of manipulators, and shortage of welding technicians, and achieve low manufacturing and operating costs, convenient and fast loading and unloading maintenance, and significant prompting effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

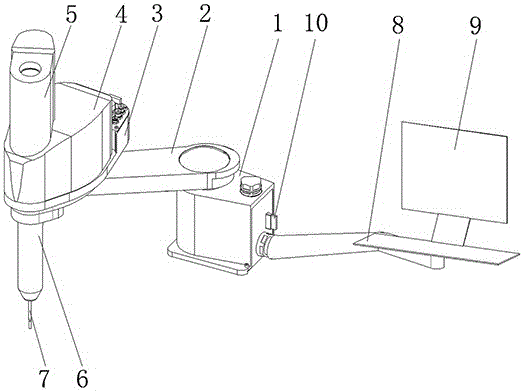

[0024] Such as figure 1 As shown, an intelligent automatic welding manipulator of this embodiment includes: a base 1, a first articulated arm 2, a second articulated arm 3, a fixed base 4, a lifting motor 5, a sliding sleeve 6, a welding gun 7, and PLC control Device 8, display panel 9 and automatic alarm device 10.

[0025] The connection relationship of the above-mentioned components is as follows: the two ends of the first articulated arm 2 are respectively connected to the base 1 and the second articulated arm 3, and both the first articulated arm 2 and the second articulated arm 3 pass through the inside of the base 1. The upper surface of the second articulated arm 3 is driven by a servo motor. The upper surface of the second articulated arm 3 is connected to a fixed seat 4; the upper part of the sliding sleeve 6 passes through the second articulated arm 3 and is connected to the fixed seat 4, and a lift motor 5 is connected to the top; The welding torch 7 is fixed inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com