Wine fermentation tank

A fermentation tank and wine technology, applied in the field of wine production, can solve the problems such as the insufficient mixing of wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

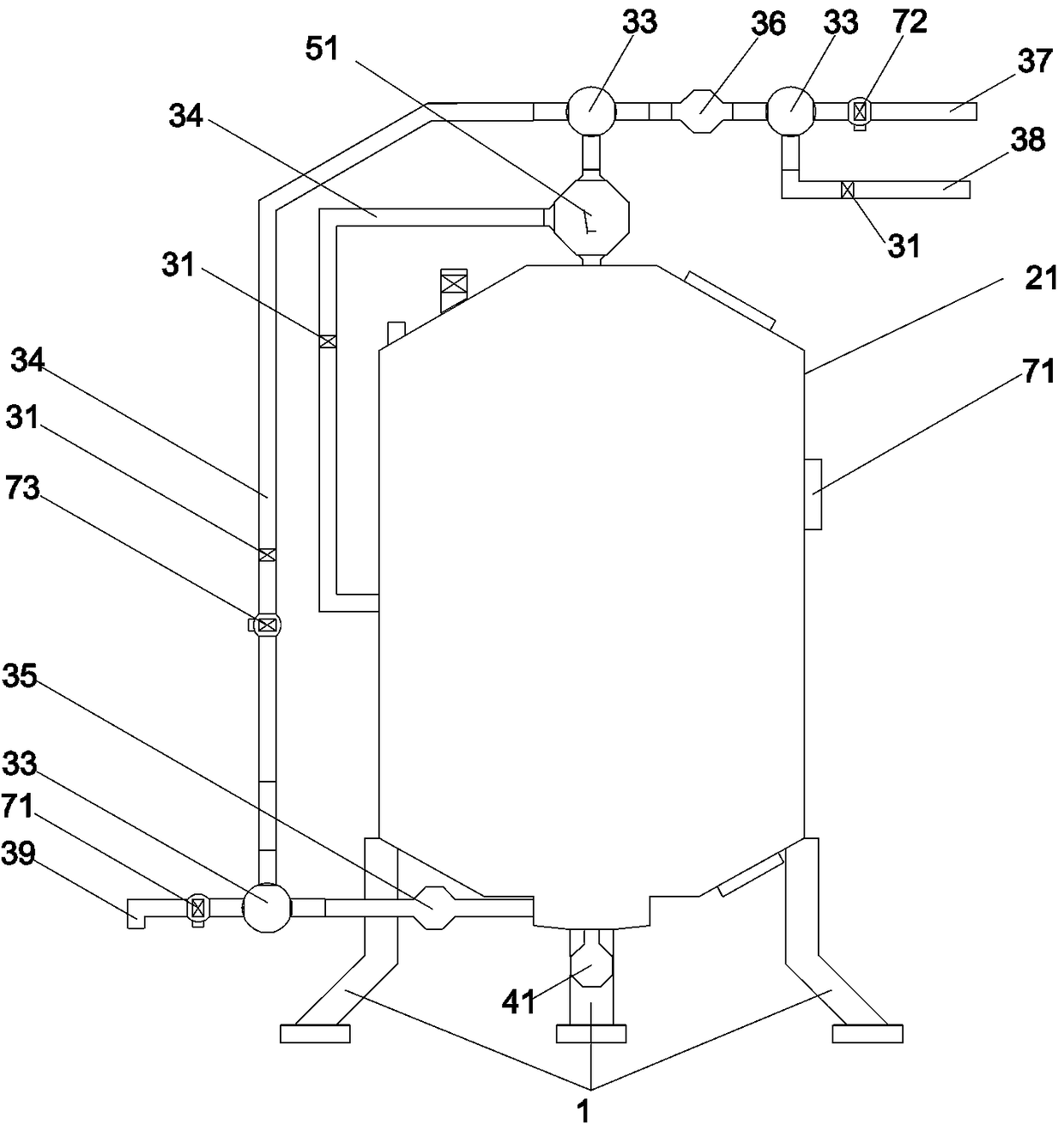

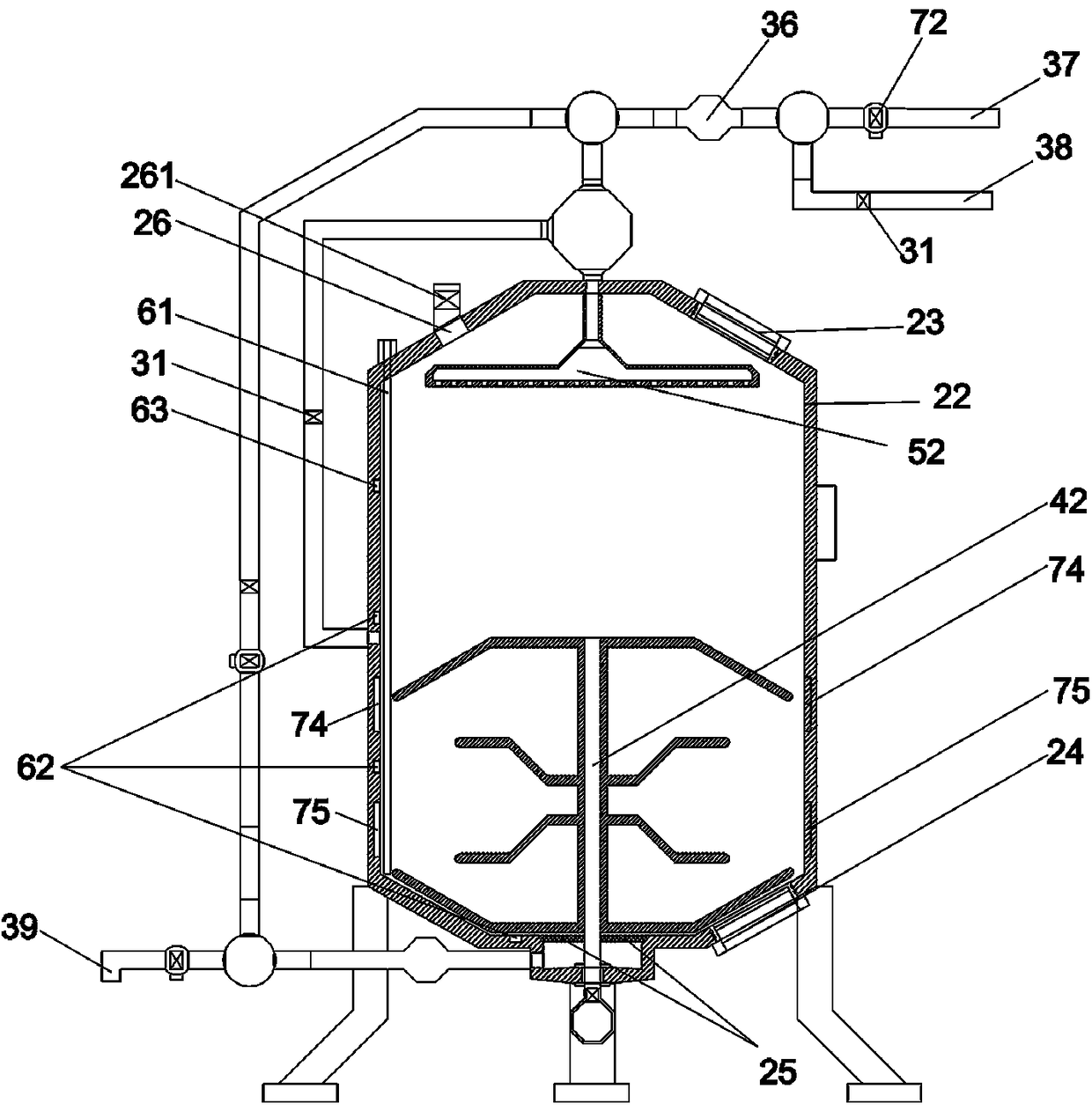

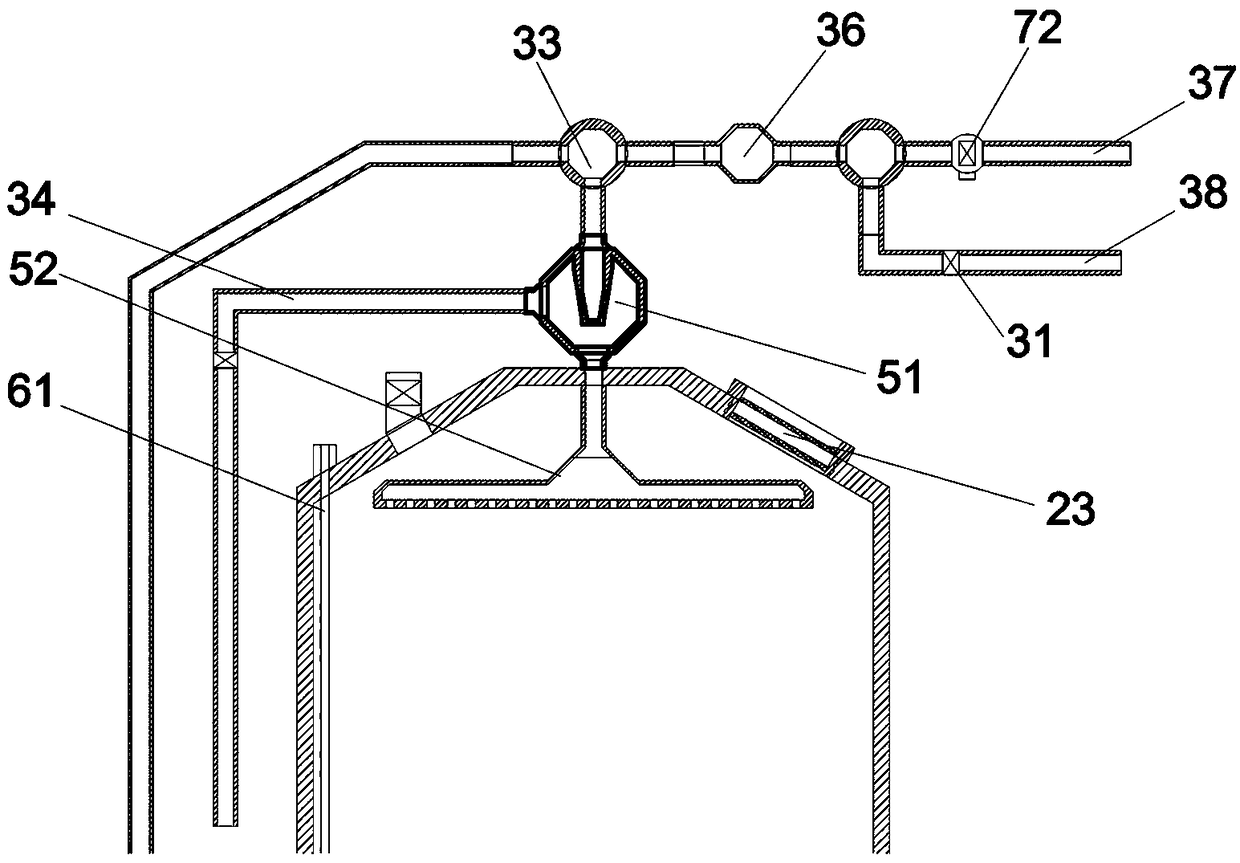

[0021] Such as figure 1 , figure 2 As shown, the wine fermentation tank includes: a base 1, a brewing tank, a circulation system, a stirring device, a mixer spray device, a monitoring system, and a control system;

[0022] The brewing tank includes: a brewing tank shell 21, a brewing tank liner 22, a feed port 23, a discharge port 24, a filter partition 25, and a vent 26;

[0023] The brewing tank is installed on the base 1; the brewing tank liner 22 is arranged in the brewing tank shell 21;

[0024] Such as Figure 5 As shown, the feed port 23 and the discharge port 24 are provided with a viewing window 231 and a double sealing strip 232;

[0025] The filter partition 25 is installed below the brewing tank liner 22, which can separate the pulp, peel and fruit wine stock solution;

[0026] The vent 26 is provided with a one-way vent valve 261;

[0027] The circulation system includes: a one-way valve 31, a tee pipe 33, a connecting pipe 34, a circulation pump 35, a suppl...

Embodiment 2

[0037] Such as figure 1 , figure 2 As shown, the wine fermentation tank includes: a base 1, a brewing tank, a circulation system, a stirring device, a mixer spray device, a monitoring system, and a control system;

[0038] The brewing tank includes: a brewing tank shell 21, a brewing tank liner 22, a feed port 23, a discharge port 24, a filter partition 25, and a vent 26;

[0039] The brewing tank is installed on the base 1; the brewing tank liner 22 is arranged in the brewing tank shell 21;

[0040] Such as Figure 5 As shown, the feed port 23 and the discharge port 24 are provided with a viewing window 231 and a double sealing strip 232;

[0041] The filter partition 25 is installed below the brewing tank liner 22, which can separate the pulp, peel and fruit wine stock solution;

[0042] The vent 26 is provided with a one-way vent valve 261;

[0043] The circulation system includes: a one-way valve 31, a tee pipe 33, a connecting pipe 34, a circulation pump 35, a supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com