A foaming device for glutinous rice and sweet potato syrup

The technology of a foaming device and glutinous rice is applied in the field of foaming devices for glutinous rice glutinous shreds syrup, which can solve the problems of high labor intensity and insufficient mixing of glutinous rice glutinous shreds syrup, so as to speed up stirring efficiency and reduce manual labor intensity. , the effect of increasing the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

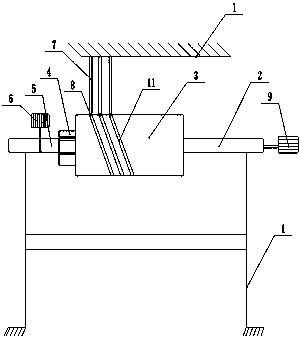

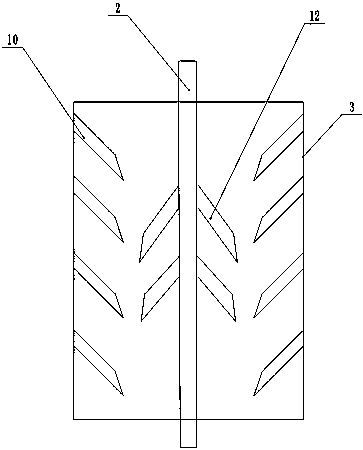

[0015] The reference numerals in the accompanying drawings of the description include a bracket 1, a rotating shaft 2, a mixing bucket 3, a spline sleeve 4, a spline shaft 5, a first rotating motor 6, a push rod 7, a roller 8, a second rotating motor 9, a second rotating motor A stirring blade 10 , an inclined annular groove 11 , and a second stirring blade 12 .

[0016] Such as figure 1 , 2 The shown glutinous rice and sweet potato syrup foaming device includes a bracket 1, a rotating shaft 2, a mixing tank 3, a spline sleeve 4, a spline shaft 5, a first rotating motor 6, a push rod 7, a roller 8, a second rotating Motor 9, first stirring blade 10, inclined annular groove 11 and second stirring blade 12. The rotating shaft 2 is erected on the support 1 and connected with the support 1 in rotation. The mixing tank 3 is made of stainless steel. The left and right ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com