A kind of equipment and method for manufacturing mold wheel laminar flow mixed absorbent core

A technology of absorbent core and mold wheel, which is applied in the field of personal hygiene, and can solve problems such as insufficient mixing of SAP and fluff pulp, SAP spilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

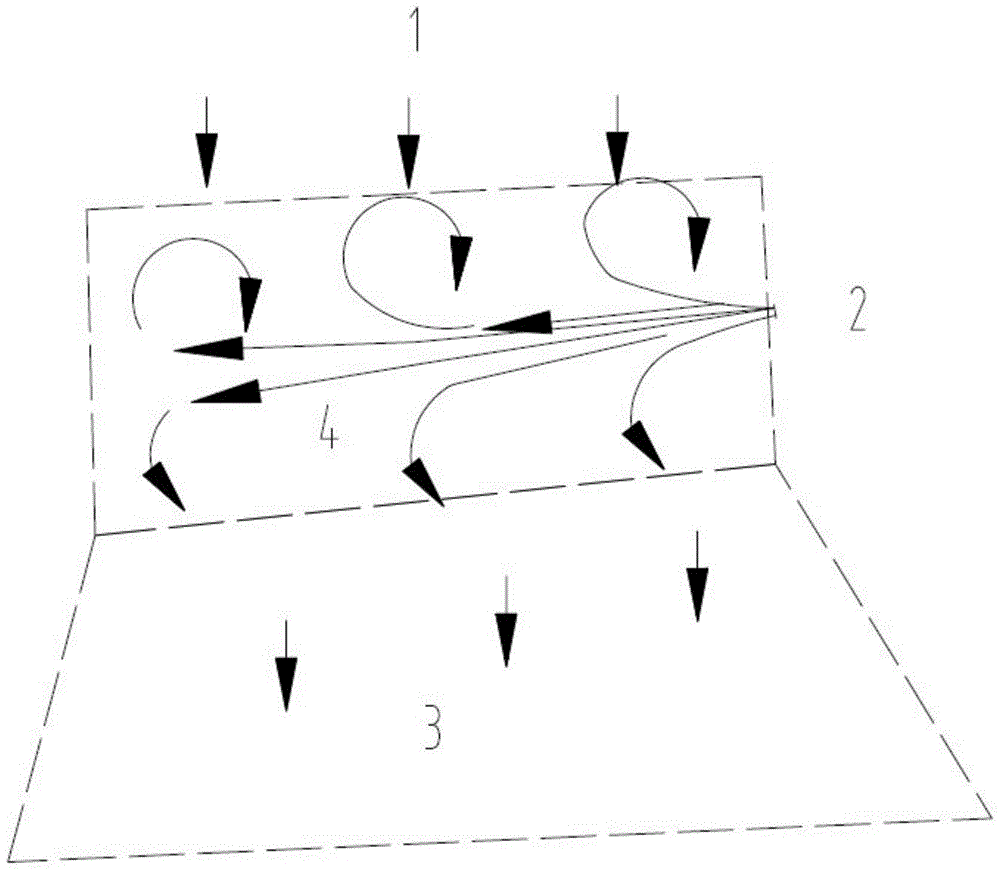

[0042] The defibrating machine (6) defibrates the fluff pulp fiberboard into fluff pulp fibers (21), and the wind force generated when the defibrating machine rotates drives the fluff pulp fibers into the mold wheel cover (1); The introduction can effectively exert the suspending and driving effect of the compressed air flow on the SAP (22) transportation; the content of SAP in the compressed air is less than 5kg / m3; when the SAP passes through the polymer water-absorbing material adding mechanism, it is positive pressure conveying, The working pressure of the compressed air is 0.3-0.8 MPa, and the preferred working pressure of the compressed air is 0.4-0.6 MPa.

[0043] SAP enters the SAP adding mechanism (7) through the SAP metering mechanism (5), the flow velocity of SAP in the SAP adding mechanism should be within 20-35m / s, and the high-speed compressed air (20) is filled into the side of the SAP adding mechanism and flows to the SAP On the other side of the adding mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com