Method for preparing geopolymer gel material and geopolymer mortar

A technology of geopolymer and cementitious materials, which is applied in the field of preparation of geopolymer cementitious materials and geopolymer mortar, can solve the problems of complex preparation process, poor operability, and poor production and application, etc. Achieve the effects of simple preparation method, low processing and production cost, and realization of processing and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

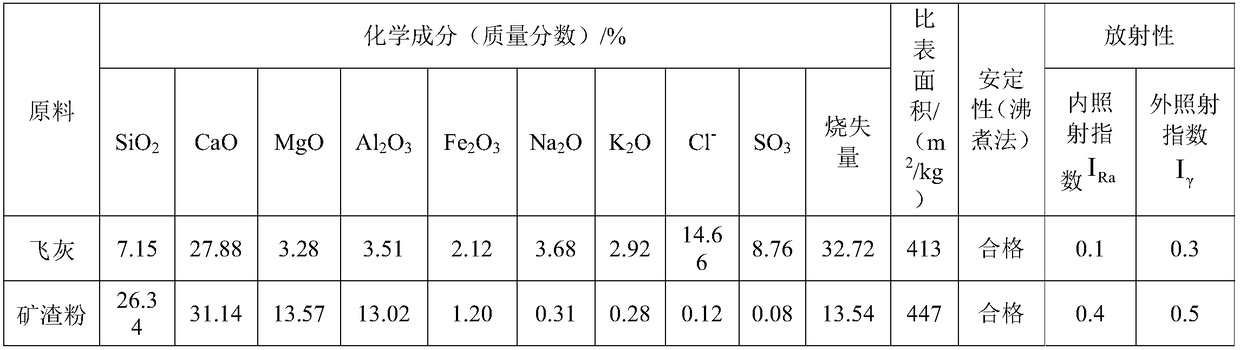

[0059] Preparation of fly ash-slag powder composite base geopolymer cementitious material:

[0060] 1) The preparation modulus is 1.3 The modulation of the composite activator:

[0061] First weigh 100 parts of water glass to prepare a composite activator with a modulus of 1.3, then weigh 10.59 parts of sodium hydroxide reagent according to the chemical composition of the water glass raw material, stir and add it to the weighed water glass, dissolve evenly and It is a composite activator with a modulus of 1.3;

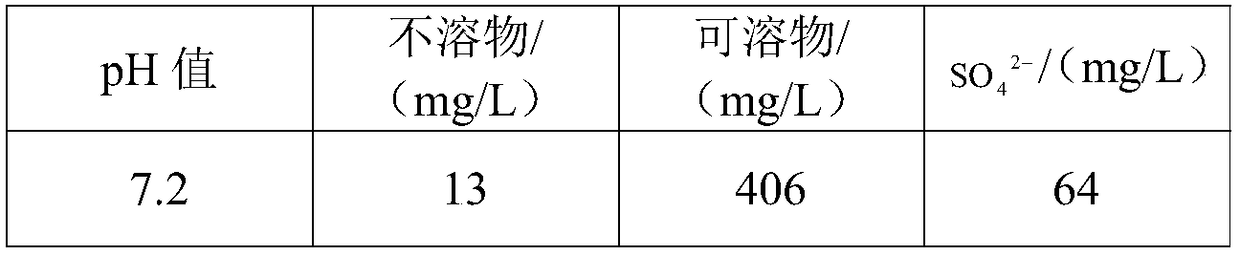

[0062] 2) Control of raw materials: the composite activator dosage is 20%, and the Si / Al molar ratio is 2.70, and the Na / Si molar ratio is 0.36, and the fly ash, slag powder, and composite activator are weighed, and the Ca / Si molar ratio is 0.89, the mixture of 100 parts of fly ash and slag powder was stirred evenly;

[0063] 3) Weigh 32 parts of mixing water (the water-binder ratio is 0.32), mix the composite activator with the mixing water, and then add it to the 1...

Embodiment 2

[0067] Production and preparation of fly ash-slag powder composite base geopolymer cementitious material:

[0068] 1) According to embodiment 1 modulation modulus is the composite exciter of 1.3;

[0069] 2) Control of raw materials: the composite activator dosage is 20%, and the Si / Al molar ratio is 2.80, and the Na / Si molar ratio is 0.42, and the fly ash, slag powder, and composite activator are weighed, and the Ca / Si molar ratio is 0.92, stir and mix 100 parts of fly ash and slag powder taken by weighing;

[0070] 3) Weigh 33 parts of mixing water (the water-cement ratio is 0.33), mix the composite activator with the mixing water, and then add it to the mixed 100 parts of fly ash and slag powder gelling components;

[0071] 4) According to Example 1, carry out stirring molding and specimen curing to obtain fly ash-slag powder composite base geopolymer gelling material.

Embodiment 3

[0073] Production and preparation of fly ash-slag powder composite base geopolymer cementitious material:

[0074] 1) According to embodiment 1 modulation modulus is the composite exciter of 1.3;

[0075] 2) Control of raw materials: the composite activator dosage is 35%, and the Si / Al molar ratio is 3.26, and the Na / Si molar ratio is 0.46, and the fly ash, slag powder, and composite activator are weighed, and the Ca / Si molar ratio is 0.70, stir and mix 100 parts of fly ash and slag powder taken by weighing;

[0076] 3) Weigh 33 parts of mixing water (the water-cement ratio is 0.33), mix the composite activator with the mixing water, and then add it to the mixed 100 parts of fly ash and slag powder gelling components;

[0077] 4) According to Example 1, carry out stirring molding and specimen curing to obtain fly ash-slag powder composite base geopolymer gelling material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com