Rolling device for spiral heat exchange pipe core in heat exchanger

A technology of heat exchange tube core and internal spiral, applied in heat exchange equipment, etc., can solve the problems of low accuracy, low production efficiency, inconvenient use, etc., and achieve the effect of convenient operation, high production efficiency, and avoiding the calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Referring to the accompanying drawings, the present invention will be further described in detail with specific embodiments.

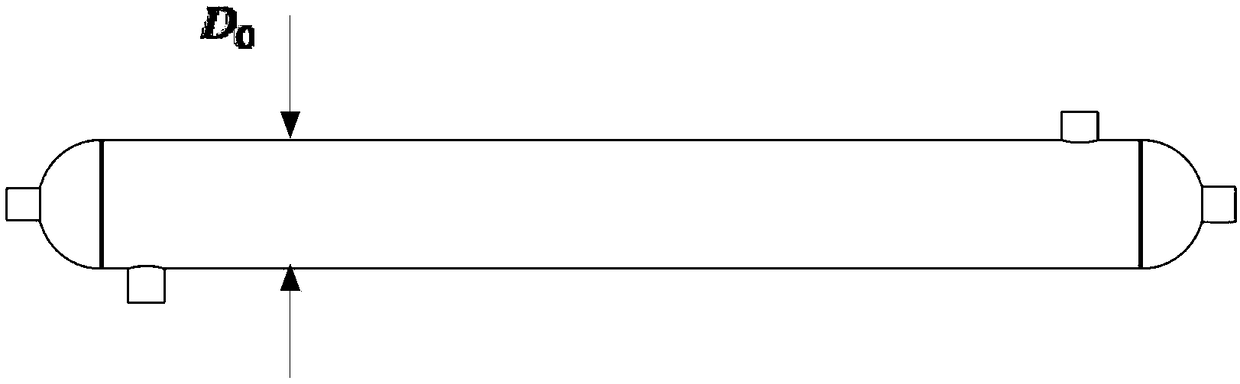

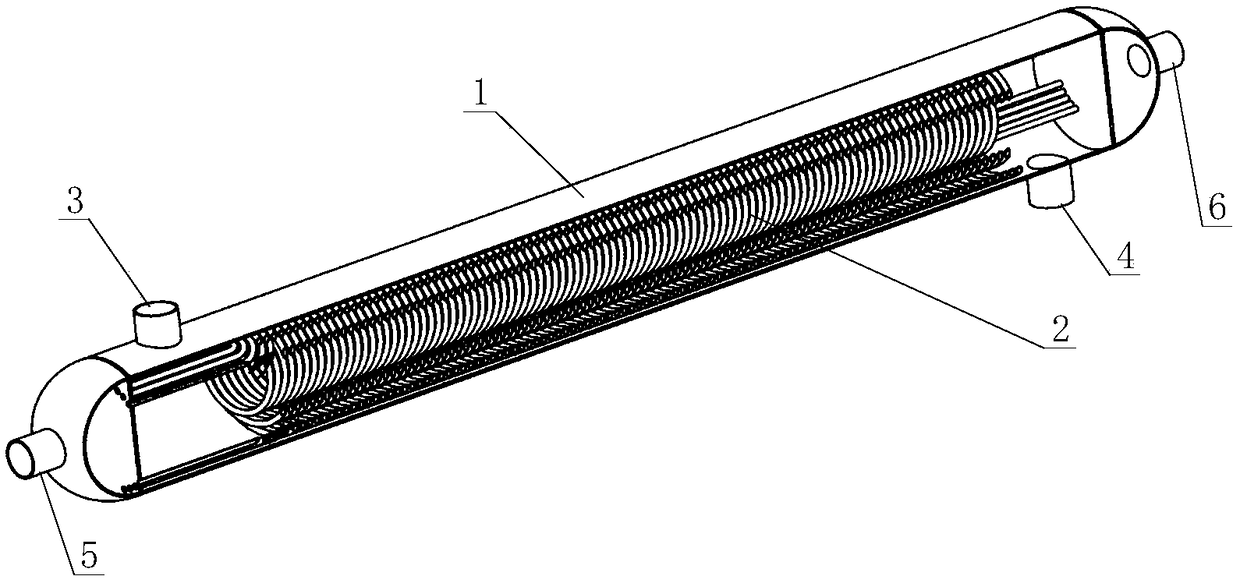

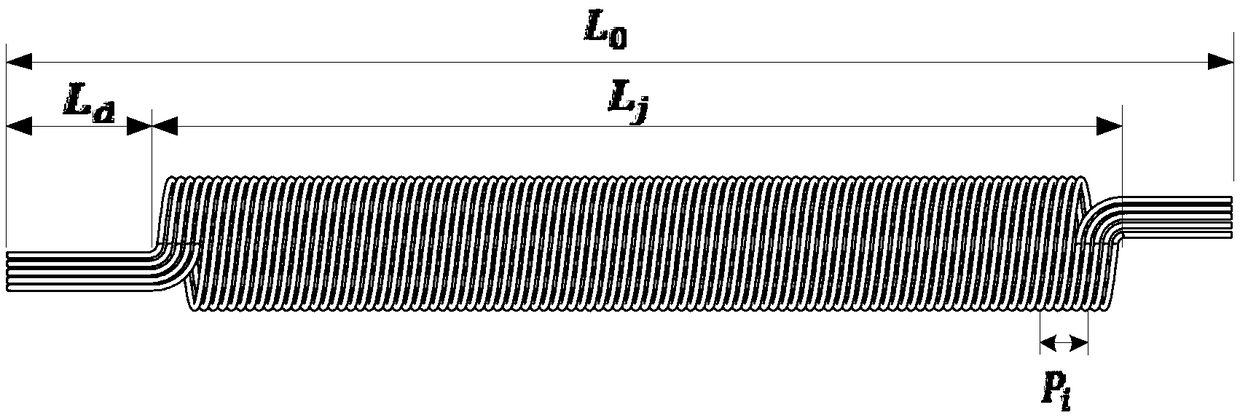

[0030] like Figure 1-2 As shown, the heat exchanger includes a shell 1, and a three-layer spiral heat exchange tube core 2 is installed in the shell 1. The housing 1 is provided with a heating medium inlet 3 , a heating medium outlet 4 , a heated fluid inlet 5 and a heated fluid outlet 6 .

[0031] like Figure 5-8 As shown, the rolling device of the spiral heat exchange tube core includes a body 7, a roller bearing seat 11, a spindle deceleration servo motor 15, a feed servo motor 16, a touch control panel 12 and a main controller are installed on the body 7, and the roller 8 One end is connected with the roller bearing seat 11, and the end face of the other end is provided with three circular holes 8-1. The sprocket shaft of sprocket wheel 13 is installed on the body 7 by bearing seat, and the sprocket wheel shaft of sprocket wheel 13 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com