Grinding wheel raw material mixing machine

A technology of mixer and raw material, applied in mixer, mixer with rotary stirring device, dissolving and other directions, can solve problems such as unfavorable production efficiency, low mixing efficiency, uneven mixing, etc., and achieve improved efficiency and effect, uniformity Good quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

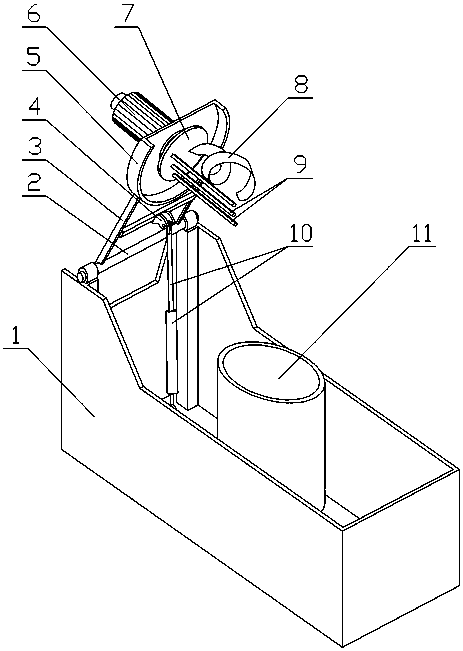

[0009] see figure 1 , the present invention is a grinding wheel raw material mixer, which has an open cabinet 1, a mixing tank 11 is provided on one side of the cabinet, and a rotating shaft 2 is arranged horizontally on the upper side of the cabinet, and is fixedly connected with the rotating shaft. A rotating plate 3 is provided, and a hinged ear 4 is arranged in the middle of the rotating plate, and a jacking cylinder 10 is arranged in the chassis below the hinged ear, the lower end of the jacking cylinder is hinged with the bottom of the chassis, and the piston rod of the jacking cylinder is connected to the bottom of the chassis. The hinged ears are hinged together; a material tank cover 5 is fixedly connected to the top of the rotating plate, and the material tank cover corresponds to the mixing tank, and a stirring motor 6 is arranged on the back of the material tank cover, and the output of the stirring motor The shaft passes through the cover plate of the material tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com