Aeroponic cultivation method

A technology of aerosol cultivation and cultivation rack, applied in the field of soilless cultivation and aerosol cultivation, can solve the problems of inability to standardize mass production, lack of large-scale production and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

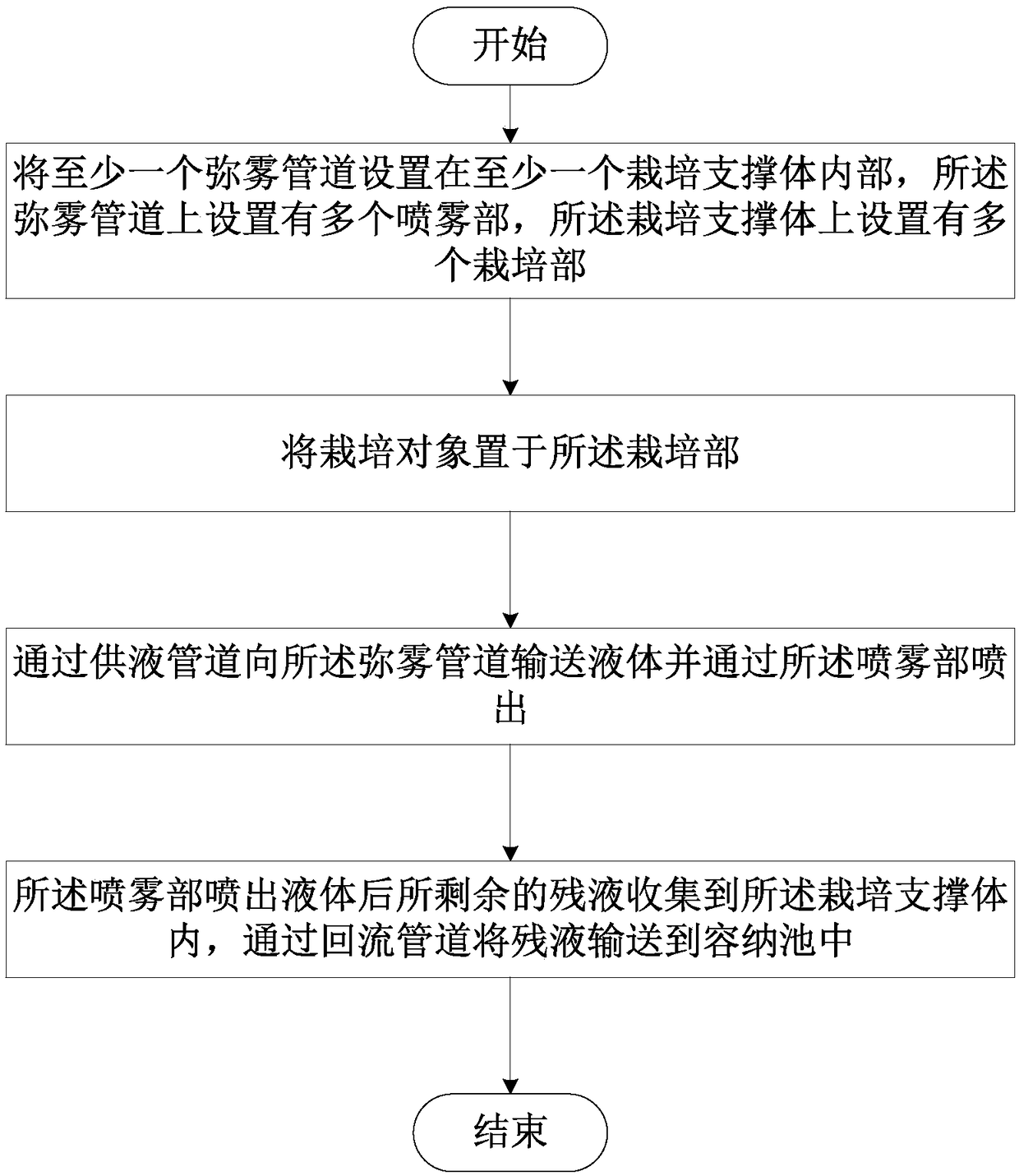

[0043] figure 1 Showing a specific embodiment of the present invention, a flow chart of an aerosol cultivation method, including the following steps:

[0044] First, step S101 is executed, at least one mist misting pipe is arranged inside at least one cultivation support body, the mist mist pipe is provided with a plurality of spraying parts, and the cultivation support body is provided with a plurality of cultivation parts. Specifically, the shape of the mist mist pipeline can be circular, square or other polygonal, the mist mist pipeline can be made by extrusion molding or injection molding process, and the spray part can be formed during the process of making the mist mist pipeline It can also be formed in one piece after the mist-misting pipeline is manufactured. For example, the spray part is a plurality of micropores on the outer surface of the mist mist pipeline, and the diameter of the micropores is between 0.1-0.3 mm. The micropores can be punched after the mist mist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com