Strengthened closed type medium-deep-layer buried pipe heat exchange system

A tube heat exchange and closed technology, applied in the direction of indirect heat exchangers, heat exchanger types, fixed tubular conduit components, etc., can solve the problem of small overall heat transfer, small temperature difference between supply and return water, and low heat transfer efficiency problems, to achieve the effect of ensuring stable results, preventing heat loss, and increasing heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

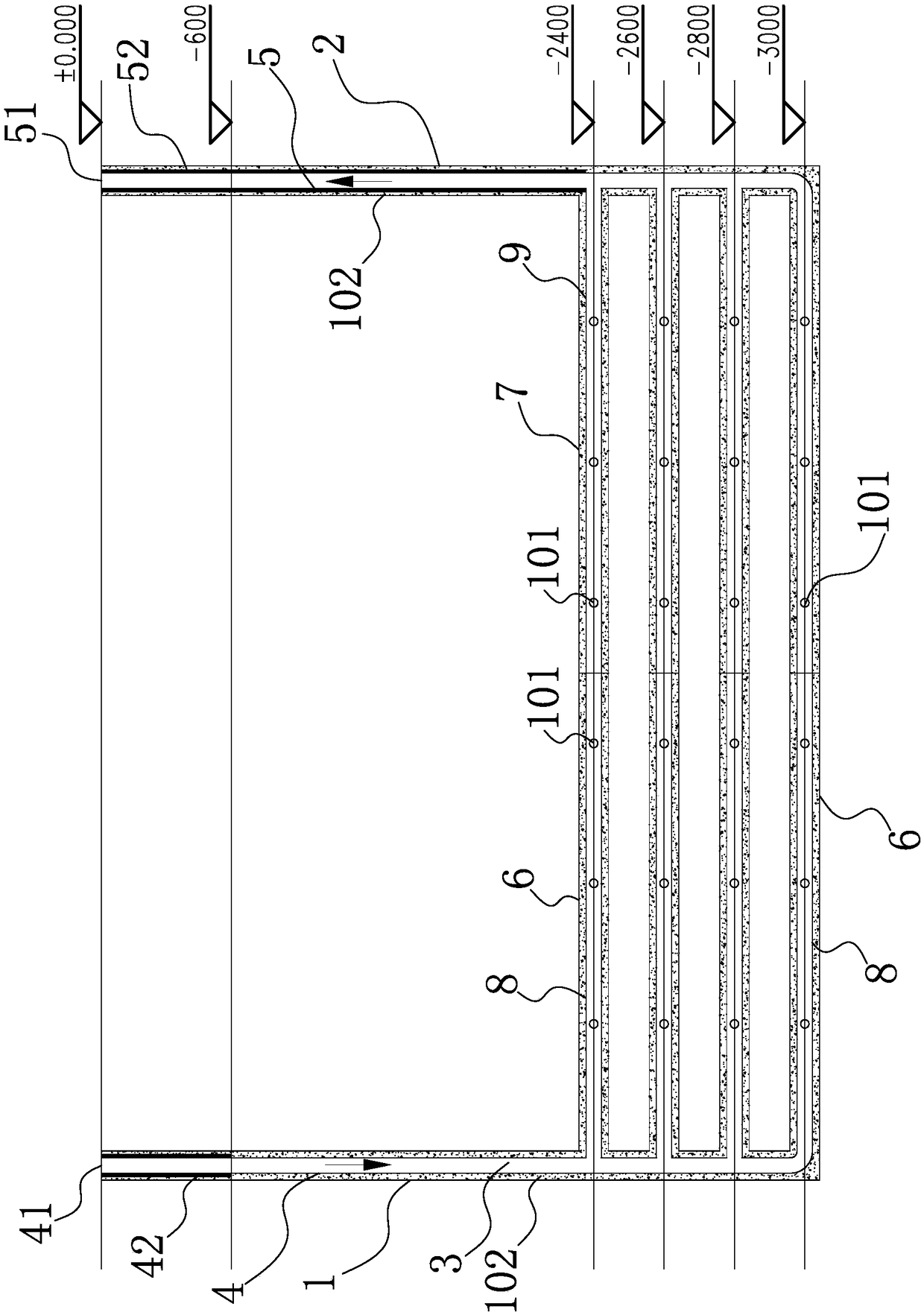

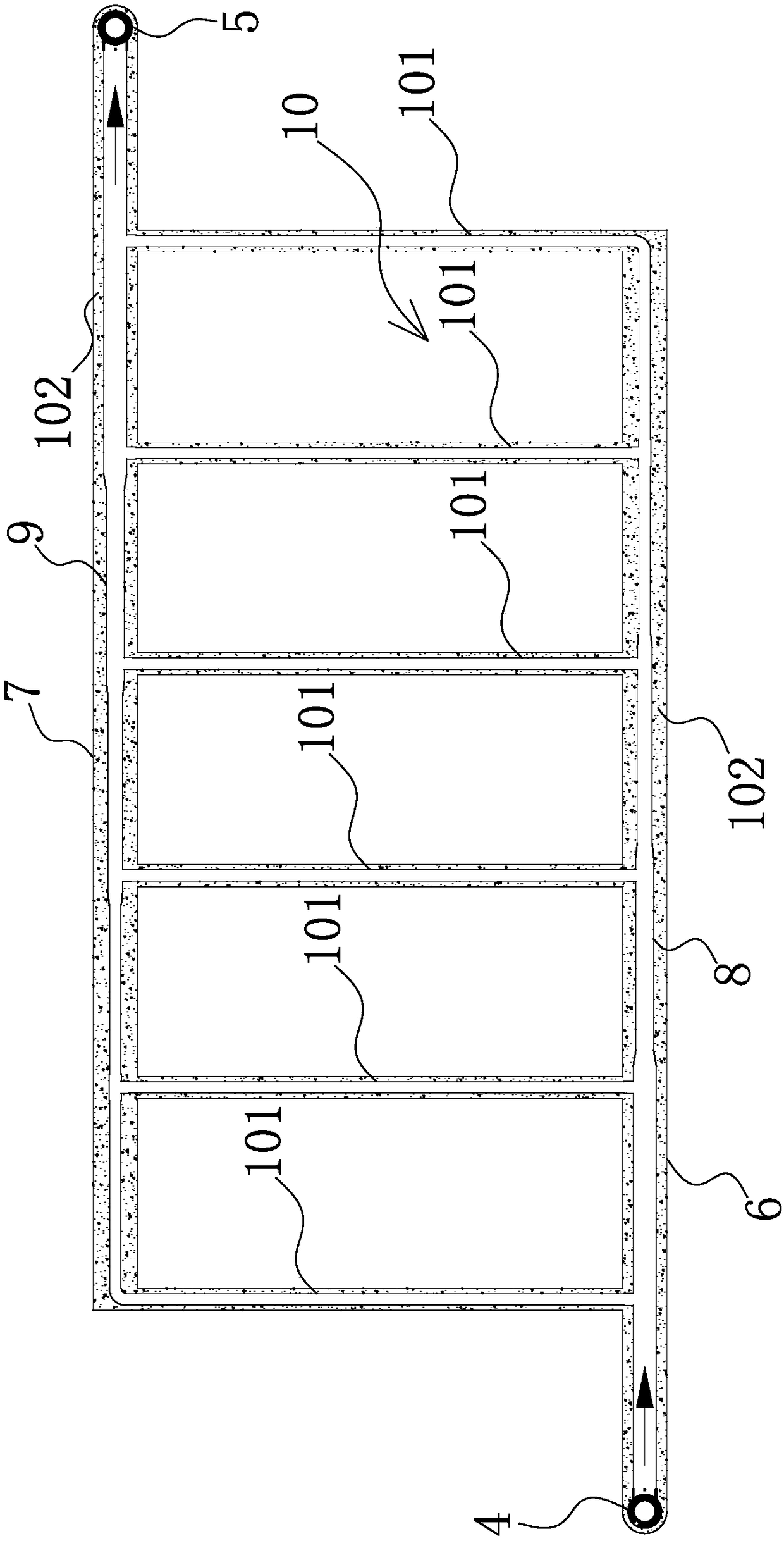

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Such as Figure 1-2 As shown, the closed medium-deep buried pipe heat exchange system includes the return water shaft 1 and the water outlet shaft 2 arranged vertically and dislocated in the horizontal direction. Here, the return water shaft 1 and the water outlet shaft 2 have the same depth. Ensure that the depth is above 3,000 meters. The return vertical shaft 1 is provided with a return vertical pipe 4 with a refrigerant 3 inside. The outlet vertical shaft 2 is provided with an outlet vertical pipe 5, and the upper end of the return vertical pipe 4 is a return pipe. The water end 41, the upper end of the water outlet vertical pipe 5 is the water outlet 51, wherein, the lower end of the backwater vertical shaft 1 is sequentially provided with a number of backwater horizontal wells 6 from top to bottom, and each backwater hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com