Foundation piling device for curve building

A technology for forming piles and foundations, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of increasing costs and unfavorable construction efficiency, and achieve strong practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

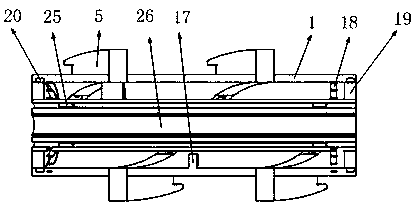

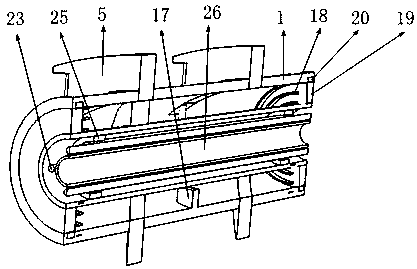

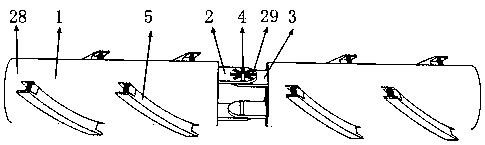

[0039] Such as figure 1 , 2 , 3, it includes a pile-forming unit 28, a connecting mechanism 29, wherein a plurality of pile-forming units 28 are connected together by the connecting mechanism 29, and between two adjacent pile-forming units 28 can be controlled by the connecting mechanism 29 The included angle.

[0040] Such as image 3 , 5 , 6, 7, 8, 9, and 10, the above-mentioned connecting mechanism 29 includes a first connecting plate 2, a second connecting plate 3, a first block 4, a block slot 6, a second block 8, a return spring 32 , Circular through hole 7, first annular support 19, guide ring 20, telescopic rotation limit rod 31, such as image 3 , 5 As shown, a guide ring 20 is installed on the outer edge surface of the first annular support 19, and two second connecting plates 3 are symmetrically installed on one side of the first annular support 19, such as Figure 7 As shown, one side of the second connecting plate 3 is provided with a block groove 6 and the other side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com