Equipment and construction method for bridge replacement

A technology for equipment and bridges, applied in the field of bridge replacement equipment and construction, can solve the problems of unfavorable suspension transportation and installation, large weight and large volume, and achieve the effect of simple and controllable operation method, reasonable equipment structure and simple and reasonable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

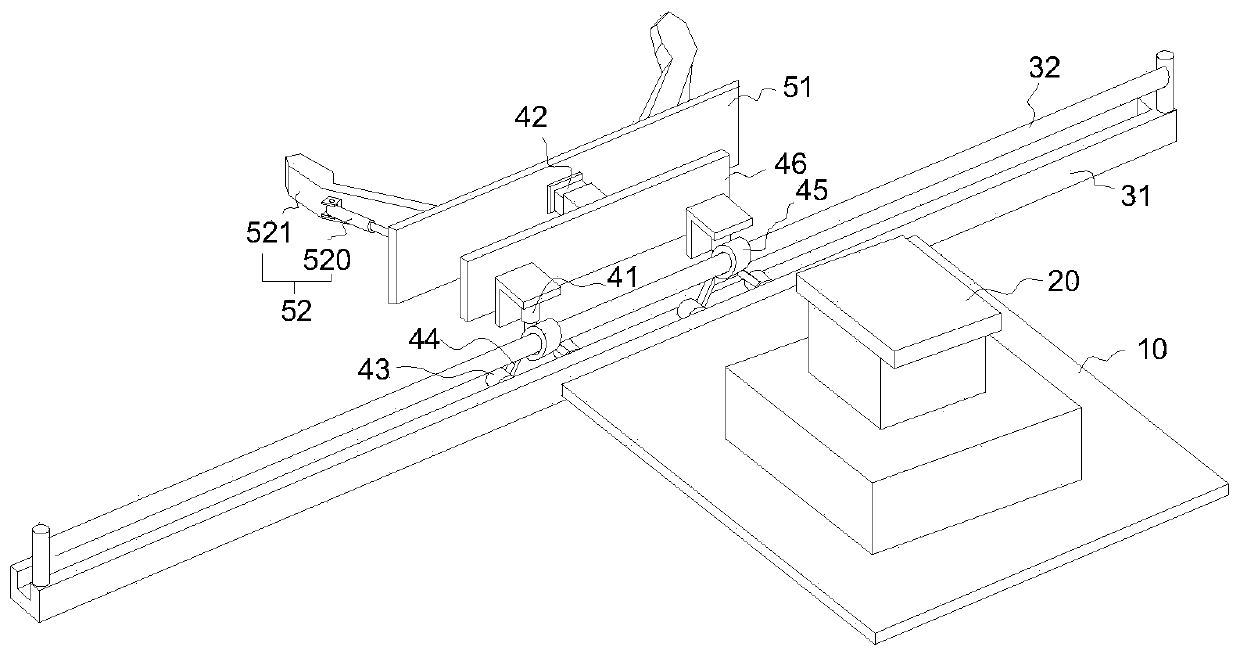

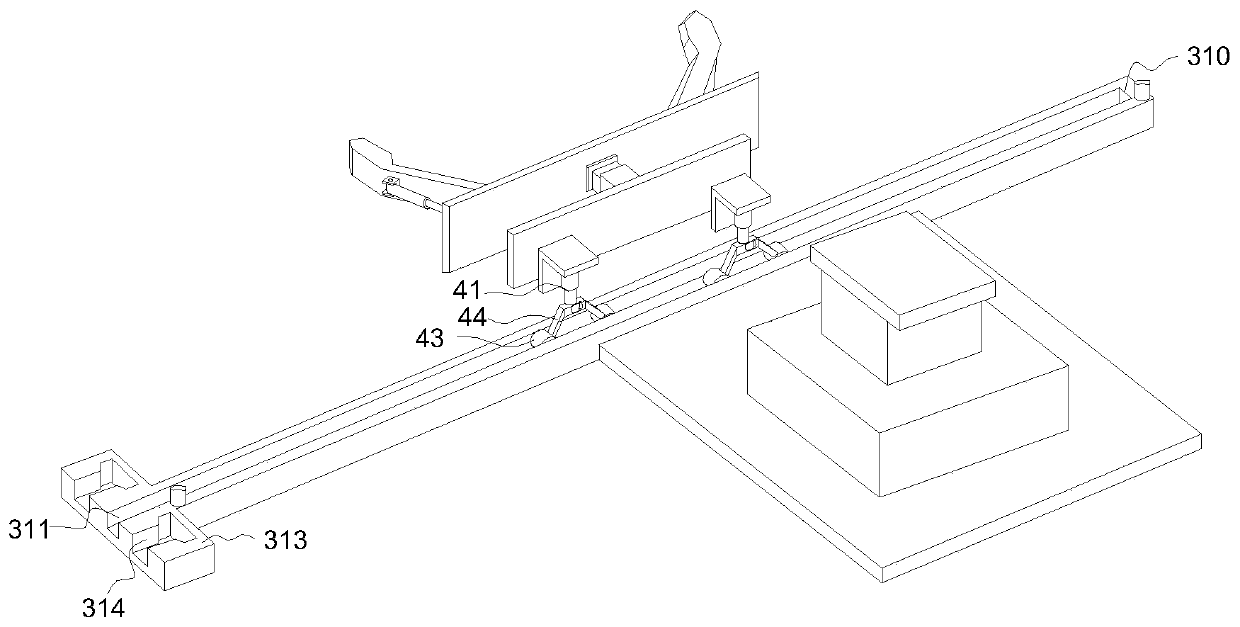

[0022] Such as figure 1 As shown, the present invention provides a device for bridge replacement, which includes a bottom plate 10, a jacking mechanism 20, a slide bar assembly, a telescopic assembly and a clamping assembly. Specifically, the jacking mechanism 20 is arranged on the bottom plate 10 . The slide bar assembly includes a strip track groove 31 connected in parallel to one side of the bottom plate 10 and a screw mechanism 32 with two ends erected on the two ends of the strip track groove 31, and one end of the screw mechanism 32 is connected with a power mechanism 33 . The telescopic assembly includes a longitudinal telescopic mechanism 41 and a horizontal telescopic mechanism 42, the bottom of the longitudinal telescopic mechanism 41 is connected with a slider 43 through a connecting rod 44, and the slider 43 is placed in the strip track groove 31, and the connection One side of the rod 44 is connected with a nut 45 matched with the screw mechanism 32 to form a sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com