Water-soluble yeast beta-glucan as well as preparation method and application thereof

A glucan and water-soluble technology, applied in the field of water-soluble yeast beta-glucan and its preparation, can solve the problems of unsatisfactory water solubility of products and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

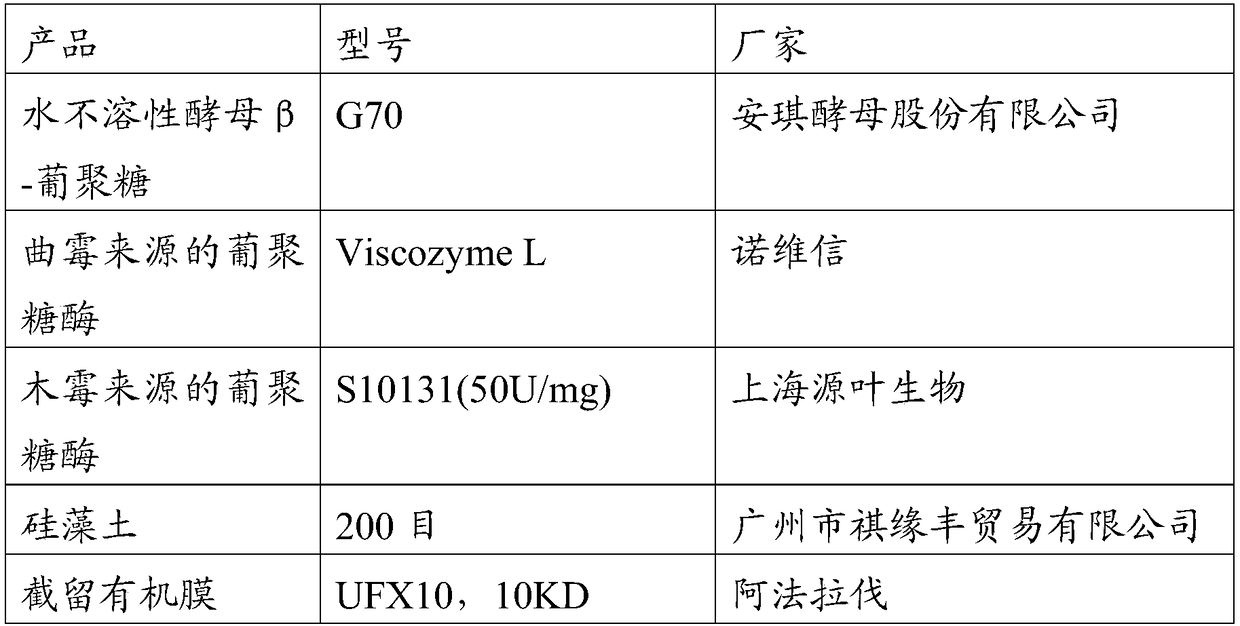

Method used

Image

Examples

Embodiment 1

[0044] Add 20kg of water-insoluble yeast β-glucan to prepare 1000L solution with purified water, adjust pH to 4.0, temperature 20°C, add glucanase to make the concentration reach 0.1U / mL, keep warm for 24h, and collect the supernatant by centrifugation. The supernatant was filtered with 100 mesh diatomaceous earth. Collect the supernatant, adjust the pH value to 7, use an organic membrane with a molecular weight cut-off of 10KD for membrane separation, collect the retentate, and obtain a total of 400L of retentate. The retentate presents a clear solution, which is water-soluble β-glucan.

[0045] The retentate was added to freeze-dry to obtain 12.1 kg of powdered water-soluble yeast β-glucan product (ie, the amount of dry matter accounted for 3.1% of the content of the retentate). The weight average molecular weight of the product is 158KD, the content of β-glucan is 85.8%, and the product yield is 60%.

[0046] Wherein, the amount of dry matter is the amount of the powdered ...

Embodiment 2

[0051] Add 100kg of water-insoluble yeast β-glucan to 1000L of purified water to prepare a solution of 1000L, adjust the pH to 7.0, the temperature is 70°C, add glucanase to make the concentration reach 5U / mL, incubate for 1 hour, and collect the supernatant by centrifugation. The supernatant was filtered with 200 mesh diatomaceous earth. Collect the supernatant, adjust the pH value to 9, use an organic membrane with a molecular weight cut-off of 10KD for membrane separation, collect the retentate, and obtain a total of 800L of retentate. The retentate presents a clear solution, which is water-soluble β-glucan.

[0052] The retentate was added to freeze-dry to obtain 56 kg of powdery water-soluble yeast β-glucan product (that is, the amount of dry matter accounted for 7% of the content of the retentate). The weight average molecular weight of the product is 366KD, the content of β-glucan is 82.1%, and the product yield is 56%.

[0053] Embodiment two adopts the same method as...

Embodiment 3

[0055] Add 50kg of water-insoluble yeast β-glucan to prepare 1000L of solution with purified water, adjust pH to 5.0, temperature at 50°C, add dextranase to make the concentration reach 1U / mL, incubate for 8h, and collect supernatant by centrifugation. The supernatant was filtered with 100 mesh diatomaceous earth. Collect the supernatant, adjust the pH value to 8, use an organic membrane with a molecular weight cut-off of 10KD for membrane separation, collect the retentate liquid, and obtain a total of 600L retentate liquid. The retentate liquid presents a clear solution, which is water-soluble β-glucan.

[0056] The retentate was added to freeze-dry to obtain 35 kg of powdery water-soluble yeast β-glucan product (that is, the amount of dry matter accounted for 5.83% of the content of the retentate). The weight average molecular weight of the product is 456KD, the content of β-glucan is 83.3%, and the product yield is 70%.

[0057] Embodiment 3 is determined by the same metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com