Fabricated thermal-insulation wallboard material capable of realizing rapid demoulding and preparation method of fabricated thermal-insulation wallboard material

A thermal insulation wall panel and prefabricated technology, which is applied in the field of building materials, can solve the problems of restricting the popularization and application of prefabricated thermal insulation wall panels, increasing production costs, long demoulding time, etc., achieving high social and environmental benefits, easy production, The effect of reducing production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

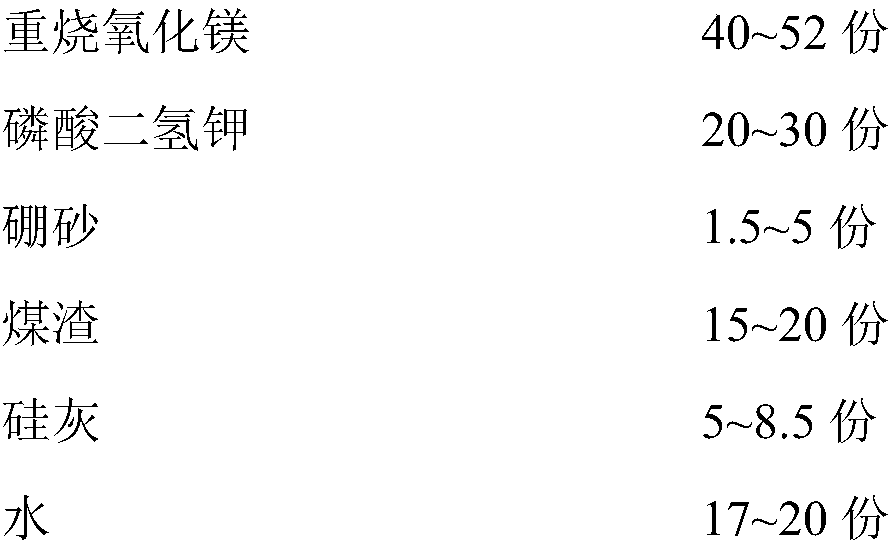

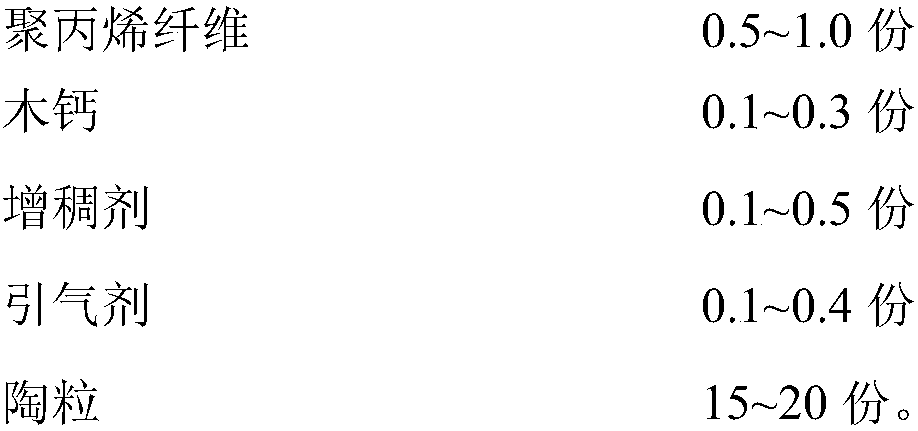

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 42 kg of dead-burned magnesia, 21 kg of potassium dihydrogen phosphate, 2 kg of borax, and 5 kg of silica fume and pour them into a stirring container, stir for 30 seconds until uniformly mixed, and obtain a solid mixture;

[0034] (2) Weigh 0.1kg of fatty alcohol polyoxyethylene ether, 0.1kg of methylcellulose, and 0.1kg of wood calcium into 18kg of water, stir for 30s until the liquid is evenly mixed, and obtain a liquid mixture;

[0035] (3) Pour the liquid mixture obtained in step (2) into the solid mixture obtained in step (1), stir at low speed for 15 seconds, and then stir at high speed for 30 seconds to form a fluid slurry;

[0036] (4) Mix the flowable slurry prepared in step (3) with 20kg of cinder and 20kg of ceramsite, first stir at a low speed for 30s, and then stir at a high speed for 30s;

[0037] (5) Mix the mixture prepared in step (4) with 0.5 kg of polypropylene fiber, stir at high speed for 30 s, prepare concrete, and discharge;

[0038] (...

Embodiment 2

[0041] (1) Weigh 43 kg of dead-burned magnesia, 22 kg of potassium dihydrogen phosphate, 2.8 kg of borax, and 6 kg of silica fume and pour them into a stirring container, stir for 30 seconds until uniformly mixed, and obtain a solid mixture;

[0042] (2) Pour 0.1 kg of fatty alcohol polyoxyethylene sodium sulfonate, 0.1 kg of hydroxypropyl methylcellulose, and 0.12 kg of wood calcium into 18 kg of water, stir for 30 seconds until the liquid is evenly mixed, and obtain a liquid mixture;

[0043] (3) mixing the solid mixture prepared in step (1) with the liquid mixture prepared in step (2), first stirring at a low speed for 30s, then stirring at a high speed for 30s to make a fluid slurry;

[0044] (4) Mix the flowable slurry prepared in step (3) with cinder 19kg and ceramsite 20kg, first stir at low speed for 30s, then stir at high speed for 30s;

[0045] (5) Mix the mixture prepared in step (4) with 0.5 kg of polypropylene fiber, stir at high speed for 30 s, prepare concrete, ...

Embodiment 3

[0049] (1) Weigh 45 kg of dead-burned magnesia, 21 kg of potassium dihydrogen phosphate, 3.1 kg of borax, and 7 kg of silica fume and pour them into a stirring container, stir for 30 seconds until uniformly mixed, and obtain a solid mixture;

[0050] (2) Pour 0.1 kg of fatty alcohol polyoxyethylene ether, 0.1 kg of sodium carboxymethyl cellulose, and 0.14 kg of wood calcium into 18 kg of water, stir for 30 seconds until the liquid is evenly mixed, and obtain a liquid mixture;

[0051] (3) Mix the solid mixture prepared in step (1) with the liquid mixture prepared in step (2), first stir at a low speed for 15 seconds, and then stir at a high speed for 30 seconds to form a fluid slurry;

[0052] (4) Mix the flowable slurry prepared in step (3) with cinder 18kg and ceramsite 20kg, first stir at low speed for 30s, then stir at high speed for 30s;

[0053] (5) Mix the mixture prepared in step (4) with 0.5 kg of polypropylene fiber, stir at high speed for 30 s, prepare concrete, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com