Forklift wheel retaining ring structure and machining technology thereof

A processing technology and retaining ring technology, which is applied to rims, vehicle parts, transportation and packaging, etc., can solve problems such as low processing efficiency, retaining rings are easily deformed by force, and lock rings are easy to pop out, so as to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0031] Aiming at the problems that the existing retaining ring is easily deformed by force, the matching lock ring is easy to pop out, the material utilization rate is low and the processing efficiency is low, the invention provides a forklift wheel retaining ring structure and a processing technology thereof.

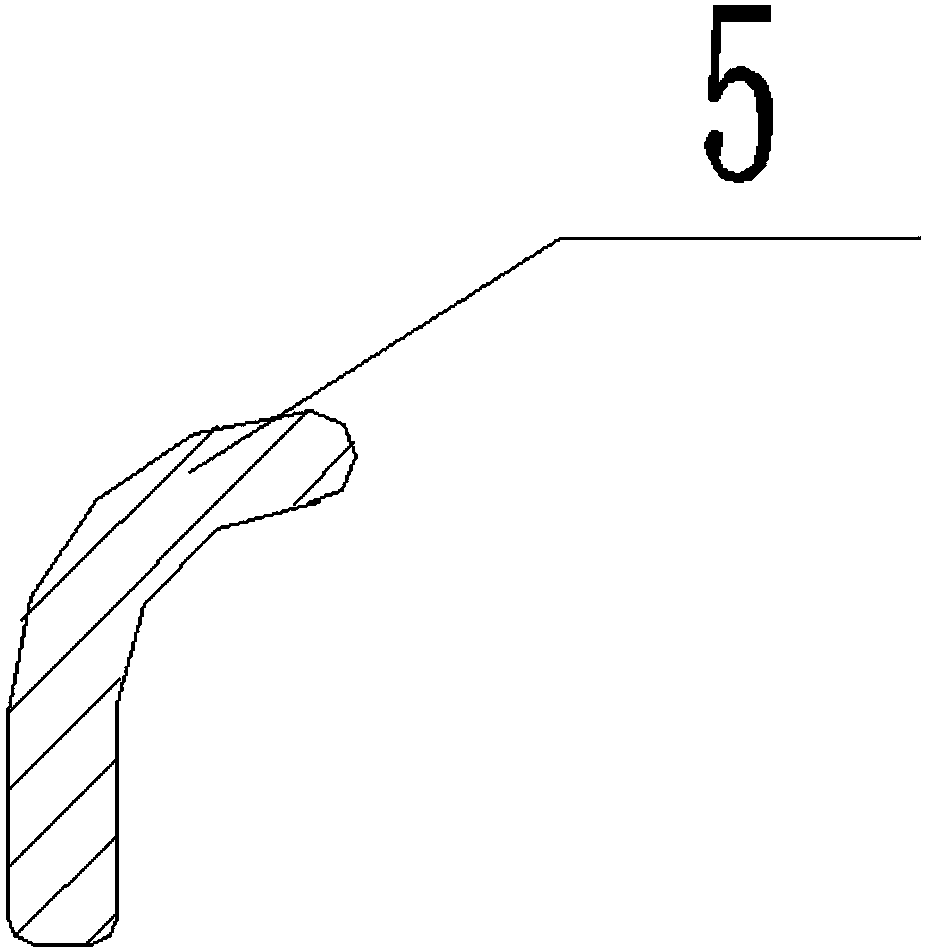

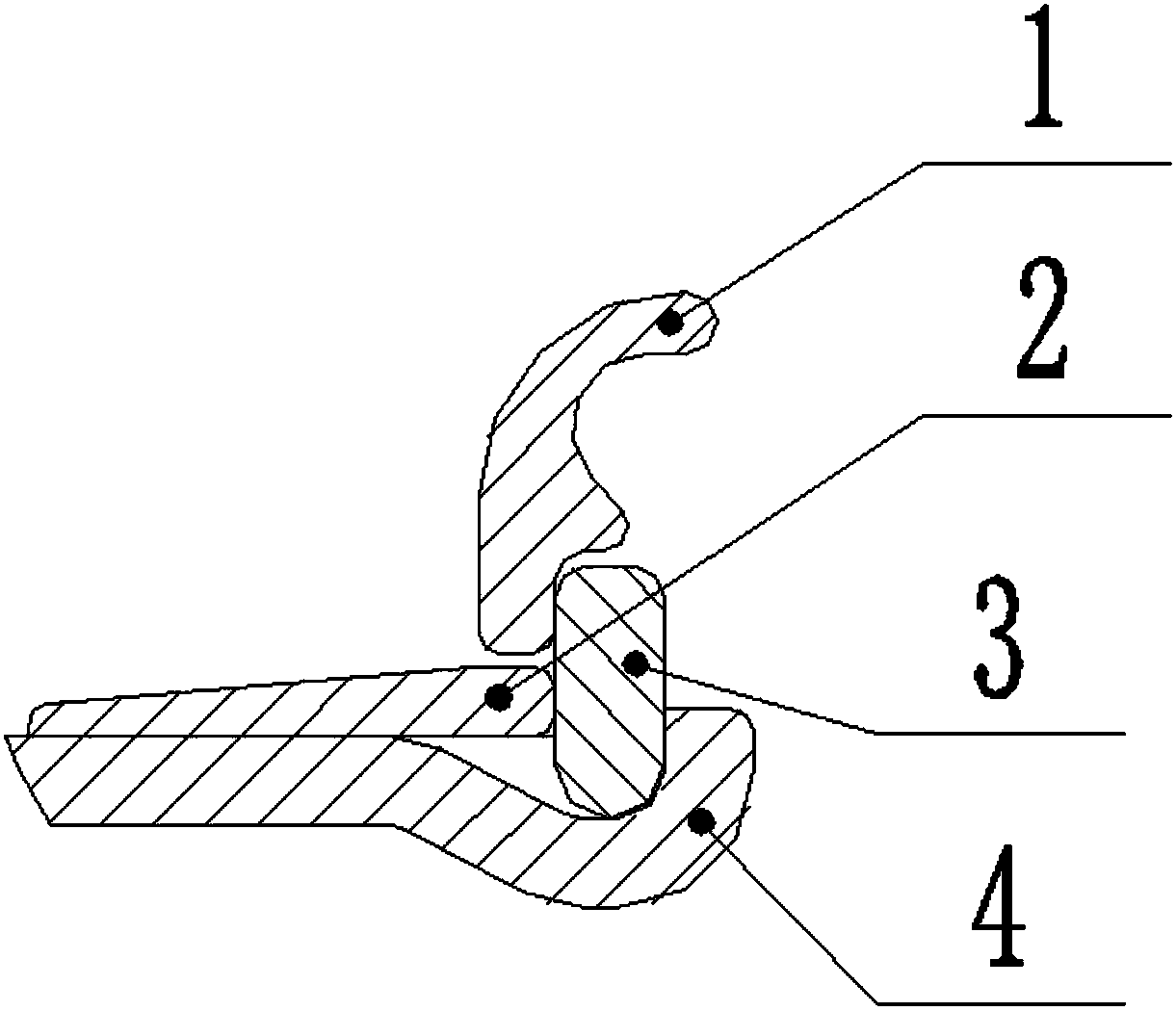

[0032] Such as Figure 2-3 As shown, the embodiment of the present invention provides a forklift wheel retaining ring structure. The outer side of the retaining ring 1 includes an integrally formed vertical outer surface 11 and an arc outer surface 12, and the inner side of the retaining ring includes an integrally formed vertical outer surface 12. The straight inner surface 13 , the protrusion 14 and the concave surface 15 , the vertical outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com