Valve cover shot blasting machine

A technology of valve cover and shot blasting machine, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., which can solve the problems of difficult surface treatment, reduced production efficiency, and rising market demand, and achieve improvement Feeding efficiency, wide shot peening area, and the effect of improving shot peening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

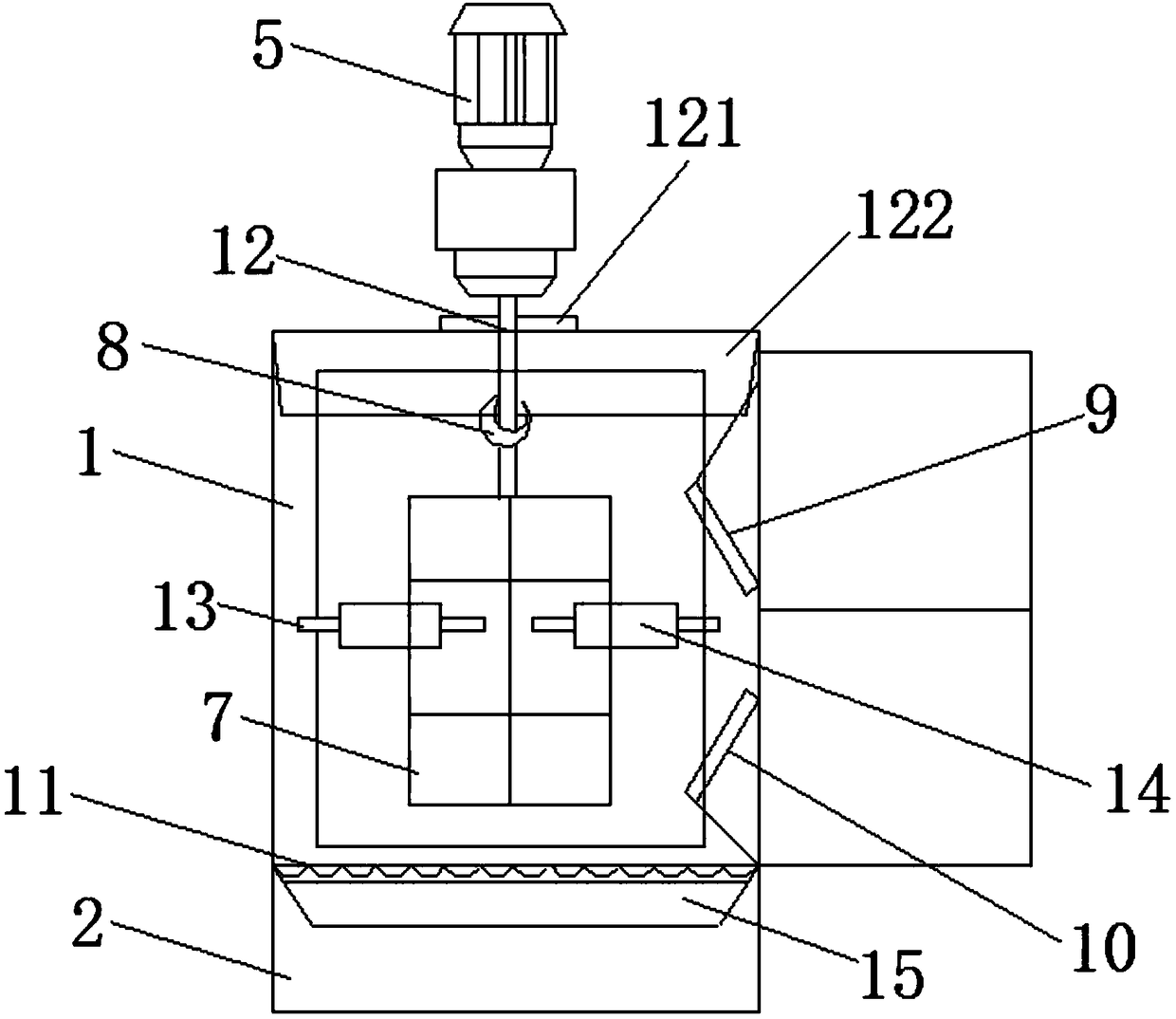

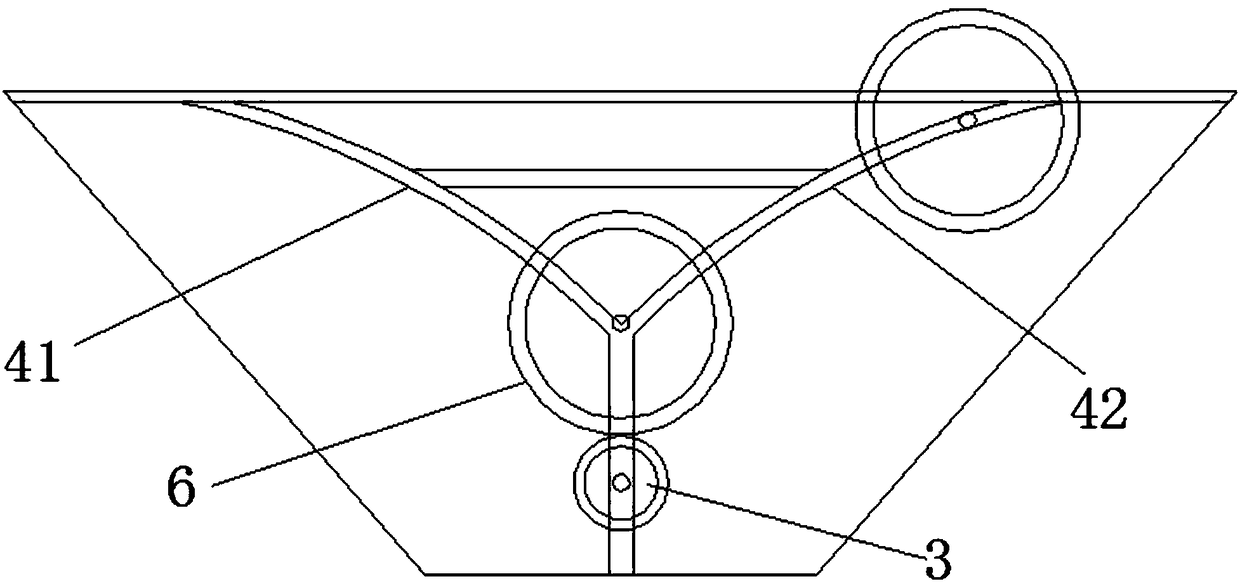

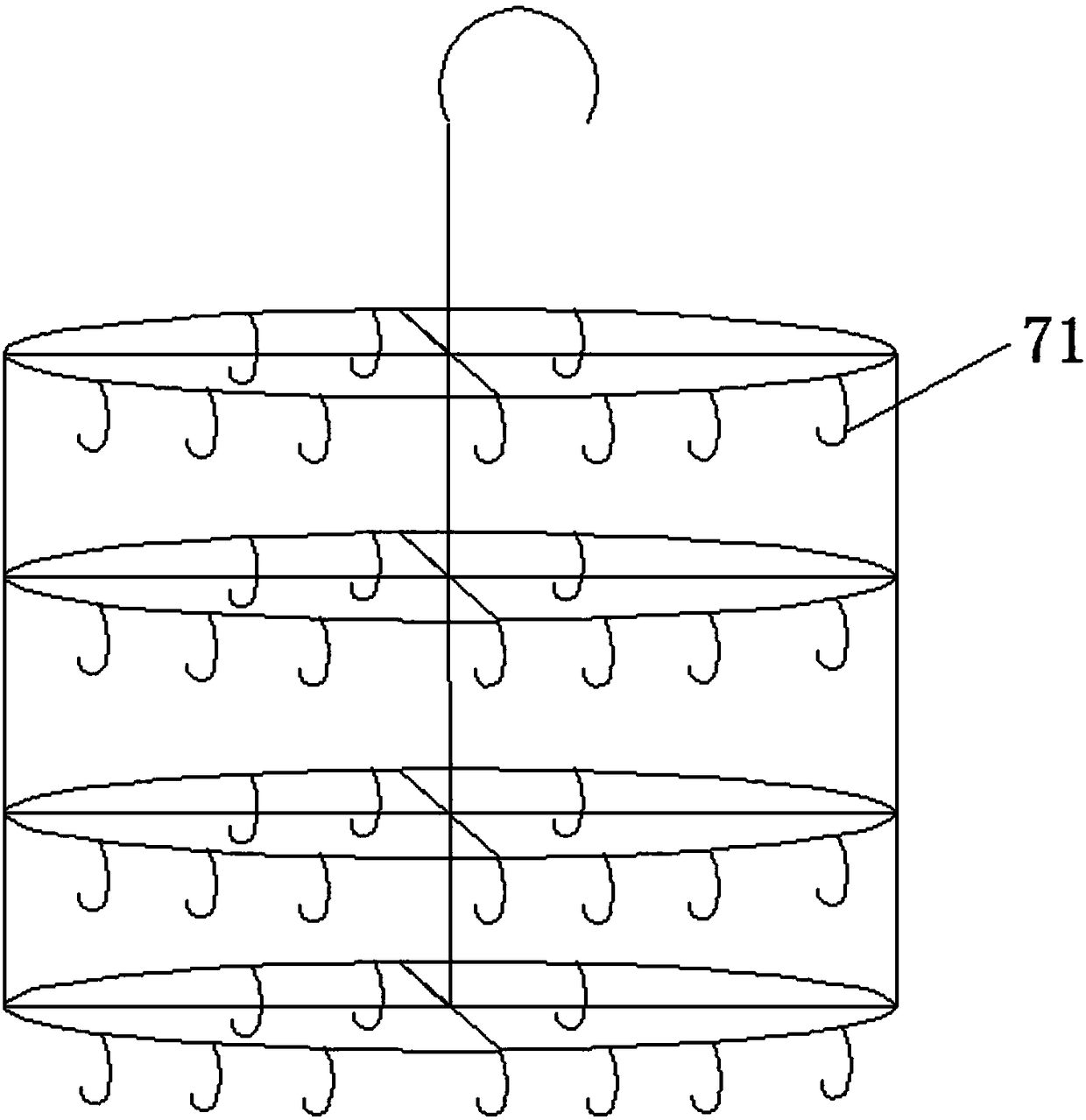

[0019] Such as figure 1 As shown, the valve cover shot blasting machine includes a shot blasting box 1, and the lower end of the shot blasting box 1 is provided with a recovery box 2 for reclaiming steel balls, and also includes a shelf 7 for surrounding the valve covers, and the shot blasting box 1 The top is provided with a rotating gear 3, a horizontal slide rail, a lifting motor 5 slidingly connected to the horizontal sliding rail, a driving mechanism for driving the lifting motor 5 to slide along the horizontal sliding rail, and a driven gear 6 cooperating with the rotating gear 3 to rotate. The driven gear 6 is connected with the output end of the lifting motor 5 by a transmission rope, the below of the driven gear 6 is connected with a hook 8 for fixing the shelf 7 through a bearing, and the upper end of the shot blasting box 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com