Deslag and sand sedimentation mechanism

A sand settling and mud cover technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., to achieve the effects of simple implementation, good cleaning effect, and good slag removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below by means of specific embodiments:

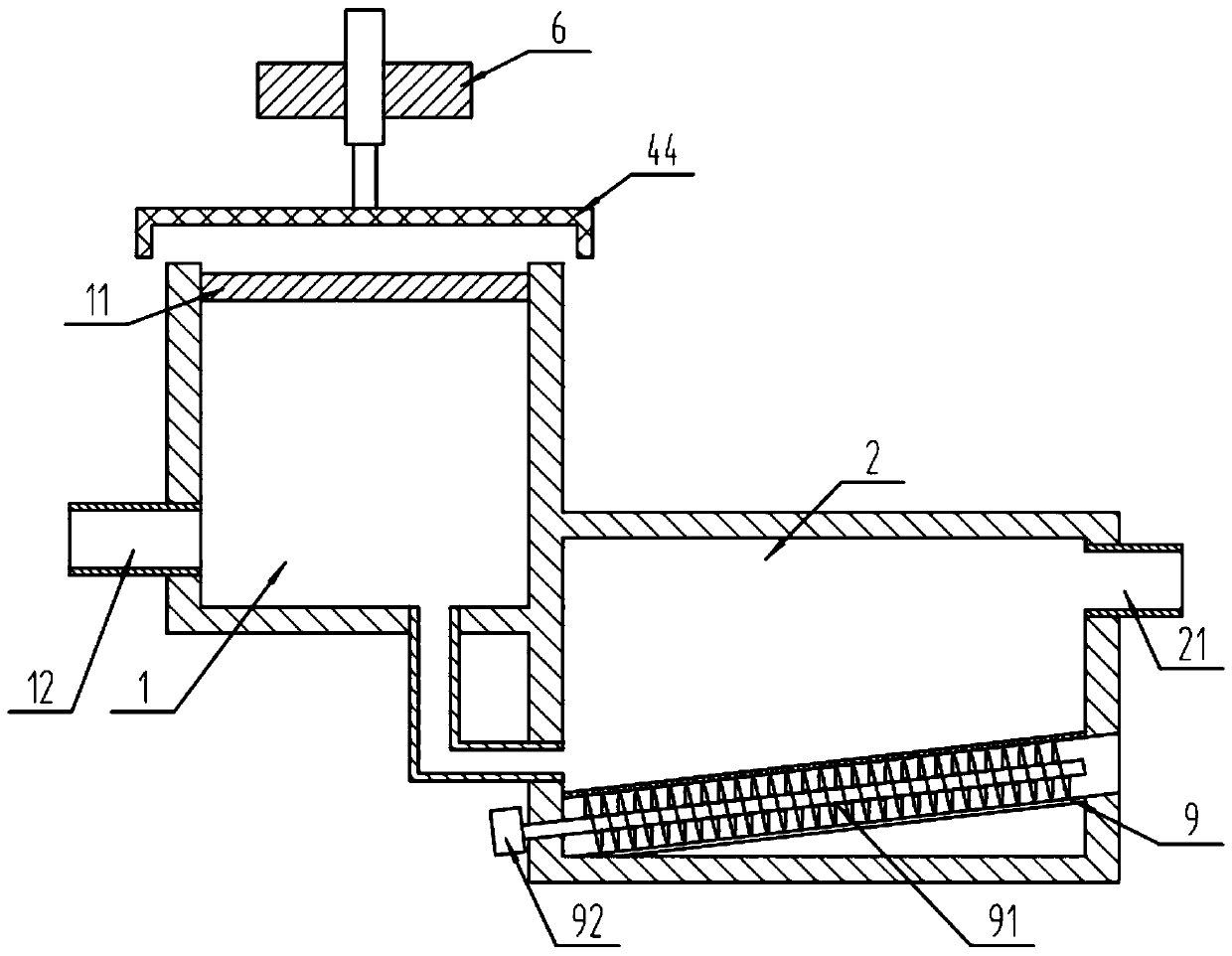

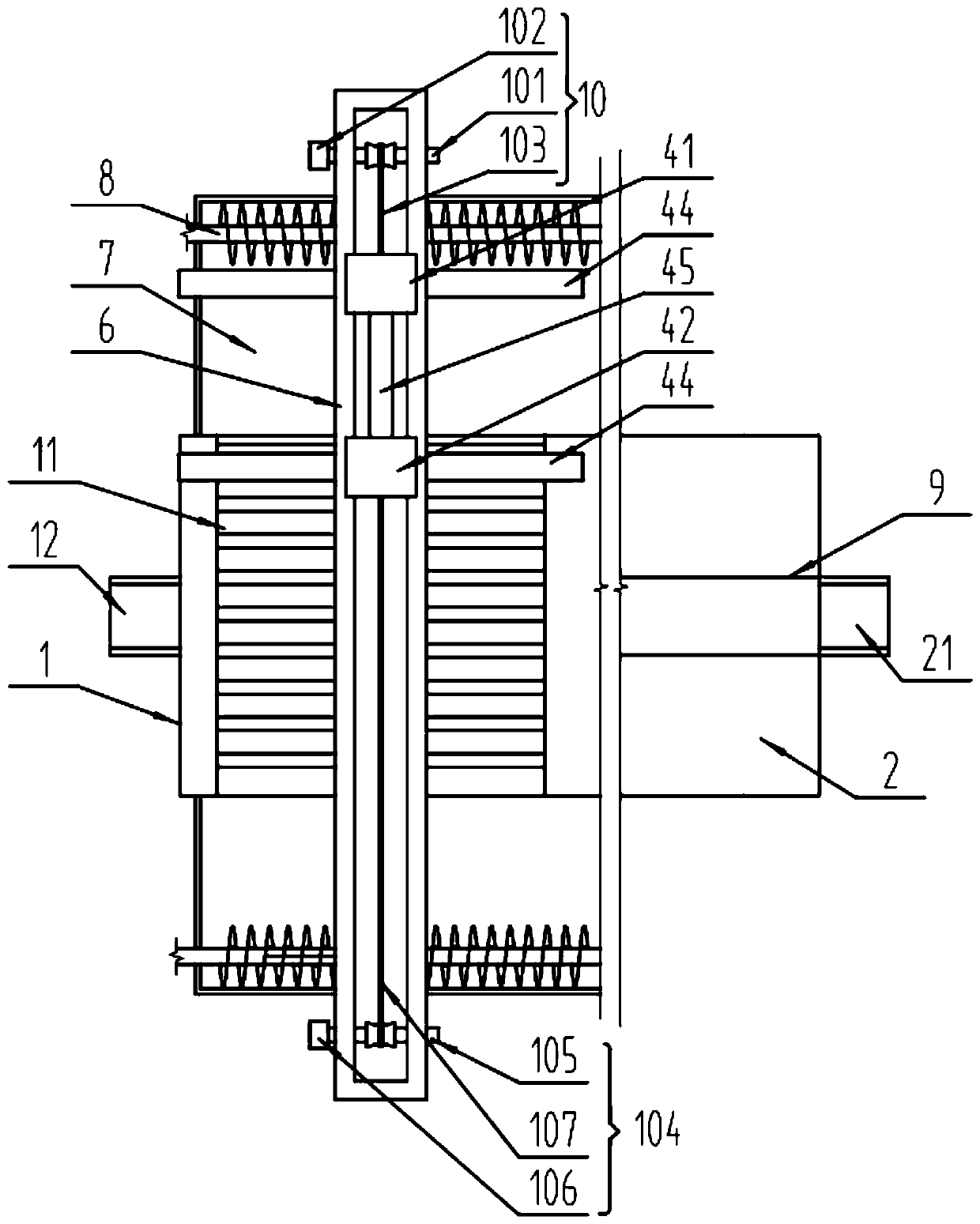

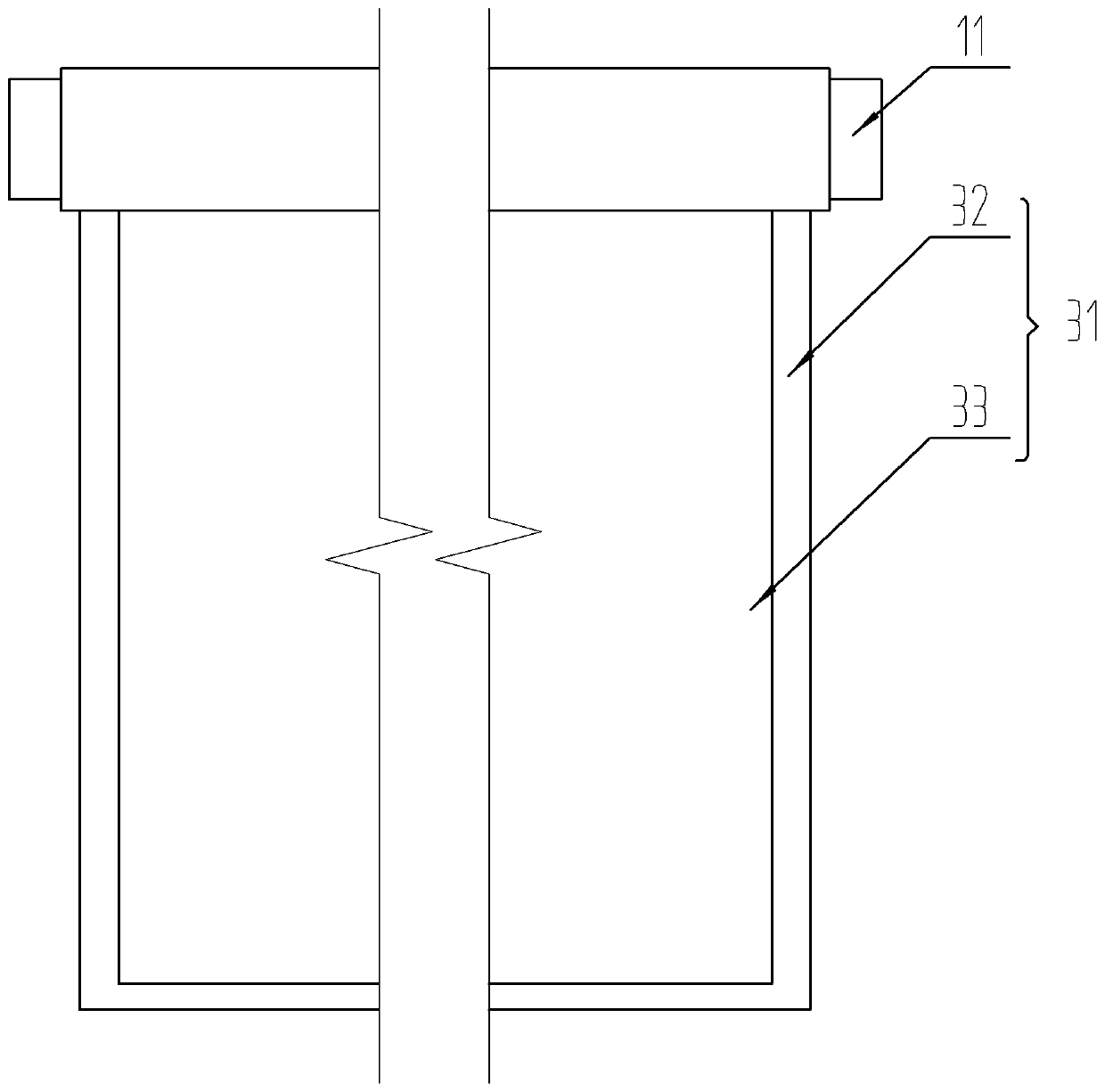

[0026] The reference signs in the drawings of the description include: water collection tank 1, horizontal bar 11, water inlet pipe 12, sedimentation tank 2, water outlet pipe 21, extrusion unit 3, upper pressing piece 31, support frame 32, extrusion plate 33, The first elastic tension cord 34, the second elastic tension cord 35, the first extruding cover 36, the second extruding cover 37, the pressing part 38, the anti-turnover protrusion 39, the first power cylinder 41, the second power Cylinder 42, pusher 44, connecting rod 45, slide rail 6, discharge chute 7, first discharge screw mechanism 8, sand settling and mud fall cover 9, second discharge screw mechanism 91, first motor 92, the first discharge screw mechanism A horizontal power mechanism 10 , a second rotating shaft 101 , a second motor 102 , a third power rope 103 , a second horizontal power mechanism 104 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com