Controller for a motor vehicle and method

一种机动车辆、控制器的技术,应用在机动车、混合动力车辆、电动汽车等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

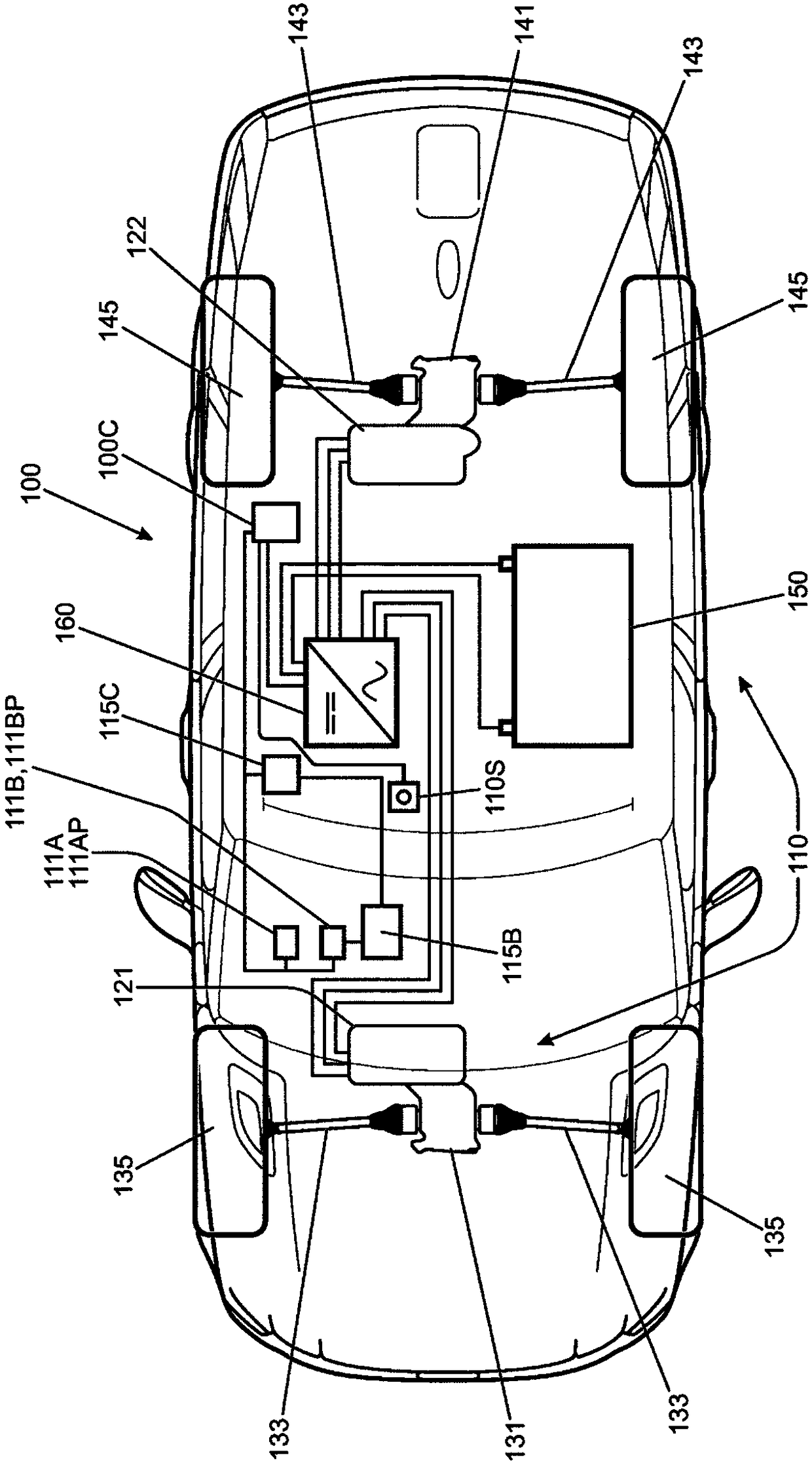

[0056] figure 1 is a schematic diagram of a vehicle 100 according to an embodiment of the present invention. The vehicle 100 has a powertrain 110 having a first electric machine 121 and a second electric machine 122 each operable as a propulsion motor (generating positive drive torque in the direction of rotation of the electric machine) or as a generator (A charge is generated by applying a negative drive torque, which is a drive torque in a direction opposite to the actual direction of rotation of the motor). The first electric machine 121 is arranged to drive a pair of front wheels 135 of the vehicle via a first torque transmitting device of the powertrain 110 having a front differential gearbox 131 and a pair of front axle shafts 133 . The second electric machine 122 is arranged to drive a pair of rear wheels 145 of the vehicle via a second torque transmitting device of the powertrain 110 having a rear differential gearbox 141 and a pair of rear axle shafts 143 . The ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com