Preparation method of thin-film resistor

A technology of thin-film resistors and metal electrodes, which is applied in the direction of resistors, circuits, electrical components, etc., can solve the problems of reducing the reliability of thin-film resistors and affecting the accuracy of thin-film resistors, and achieve the effects of improving accuracy and reliability and avoiding over-etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

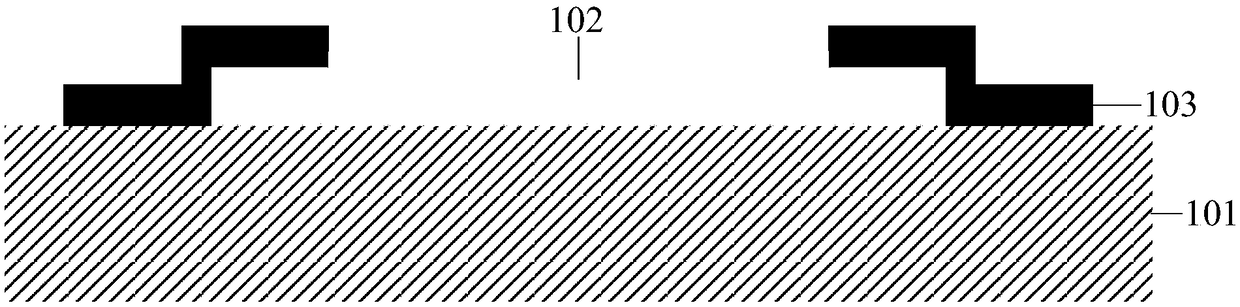

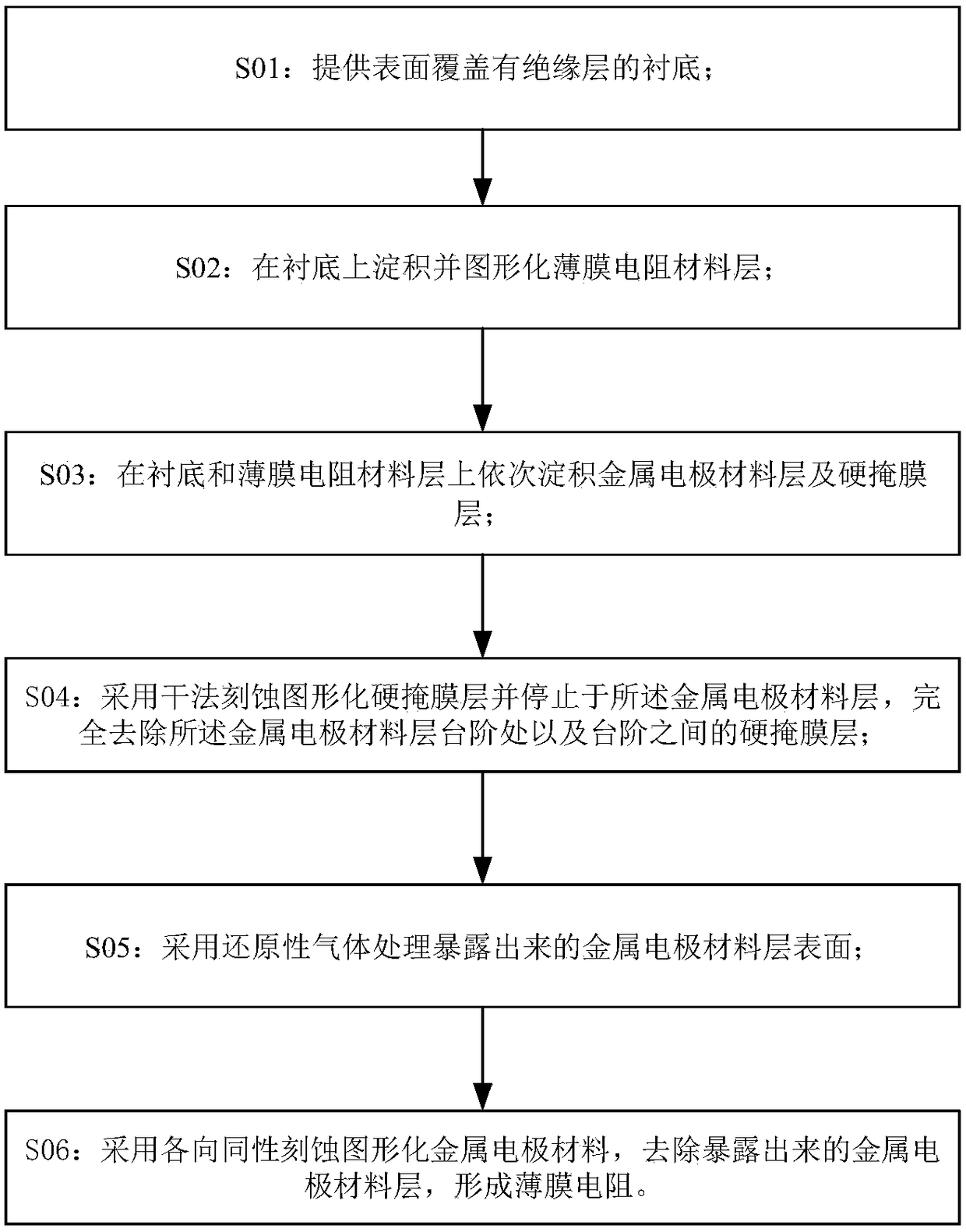

[0027] see figure 2 and image 3 , as shown in the figure is a schematic flow chart of a preferred embodiment of a method for preparing a thin film resistor of the present invention. In this embodiment, a method for preparing a thin film resistor includes the following steps:

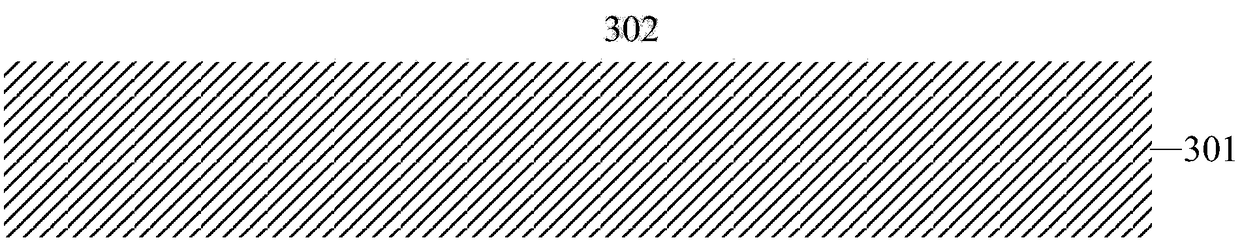

[0028] Step S01: providing a substrate whose surface is covered with an insulating layer.

[0029] Specifically, a silicon wafer is used as a substrate, and an insulating layer is deposited on the substrate. The silicon wafer substrate may be a silicon wafer on which a CMOS processing circuit chip has been manufactured. As an optional implementation, this embodiment uses an 8-inch silicon wafer as the substrate, and deposits 3000 Angstroms of sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com