Vacuum drop-out-type switch

A technology of drop switch and vacuum switch, which is applied in the direction of electric switch, high voltage/high current switch, high voltage air circuit breaker, etc. It can solve the problems of high labor cost, delay of power supply restoration, maintenance and closing operation difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

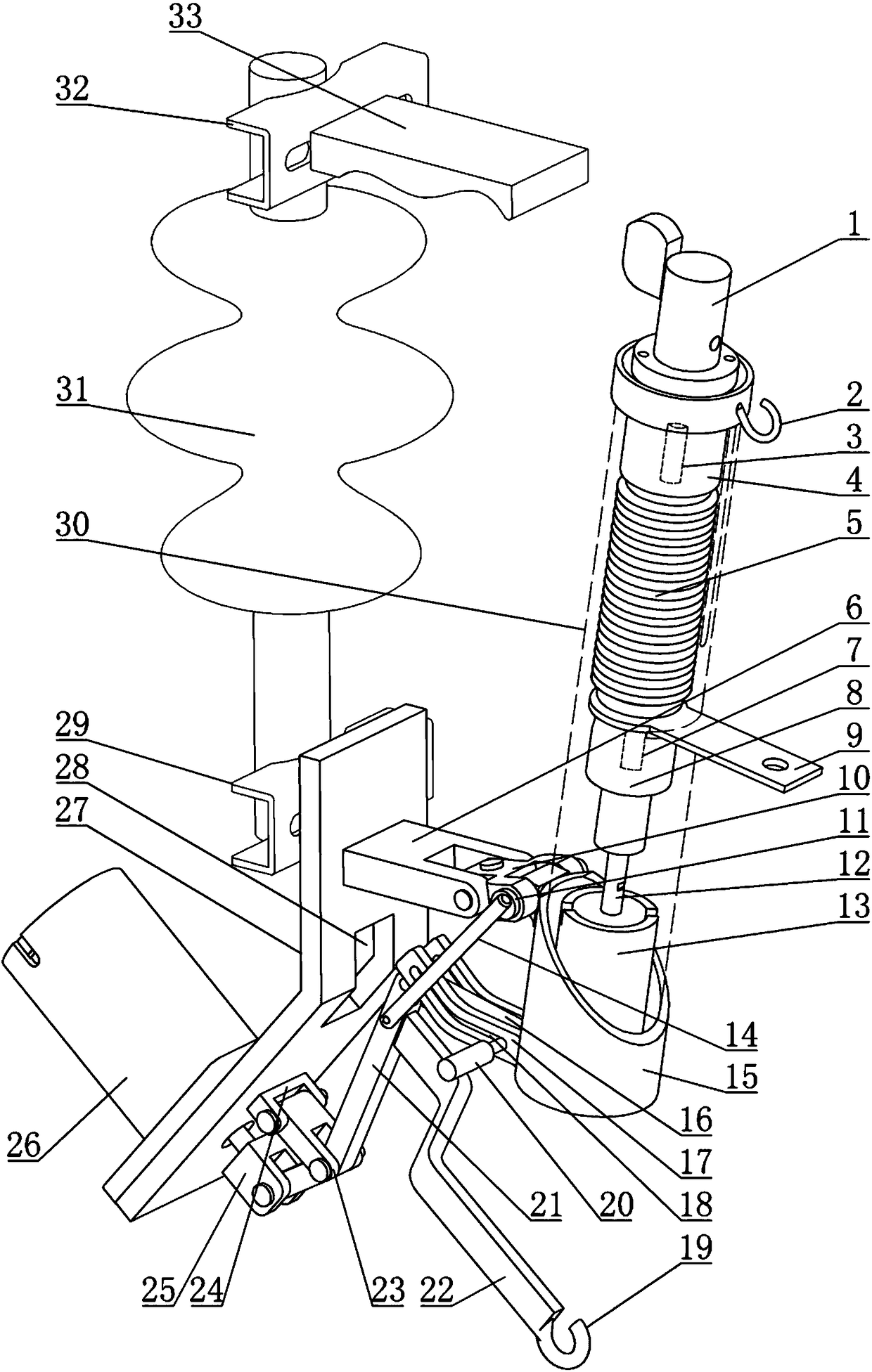

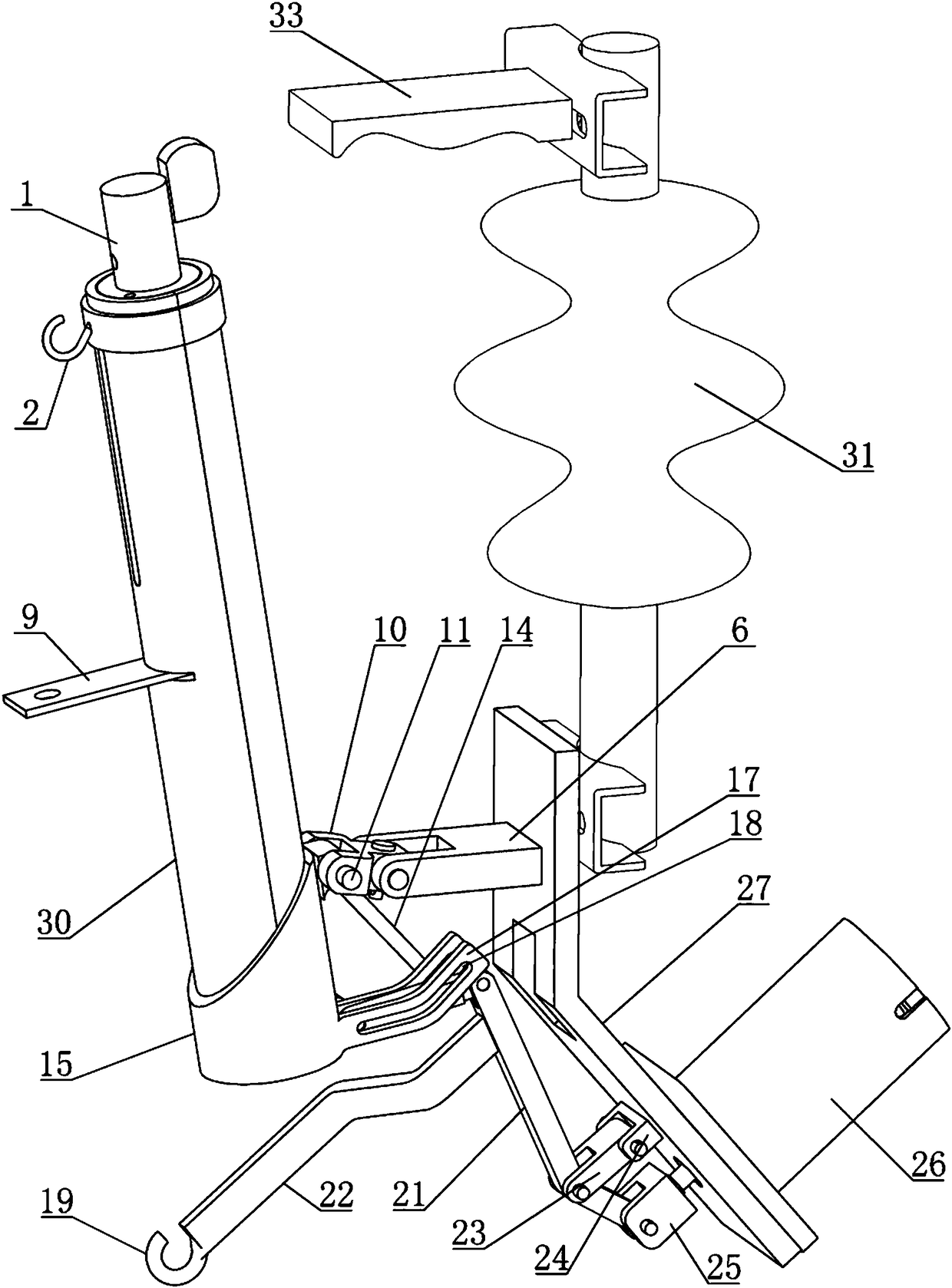

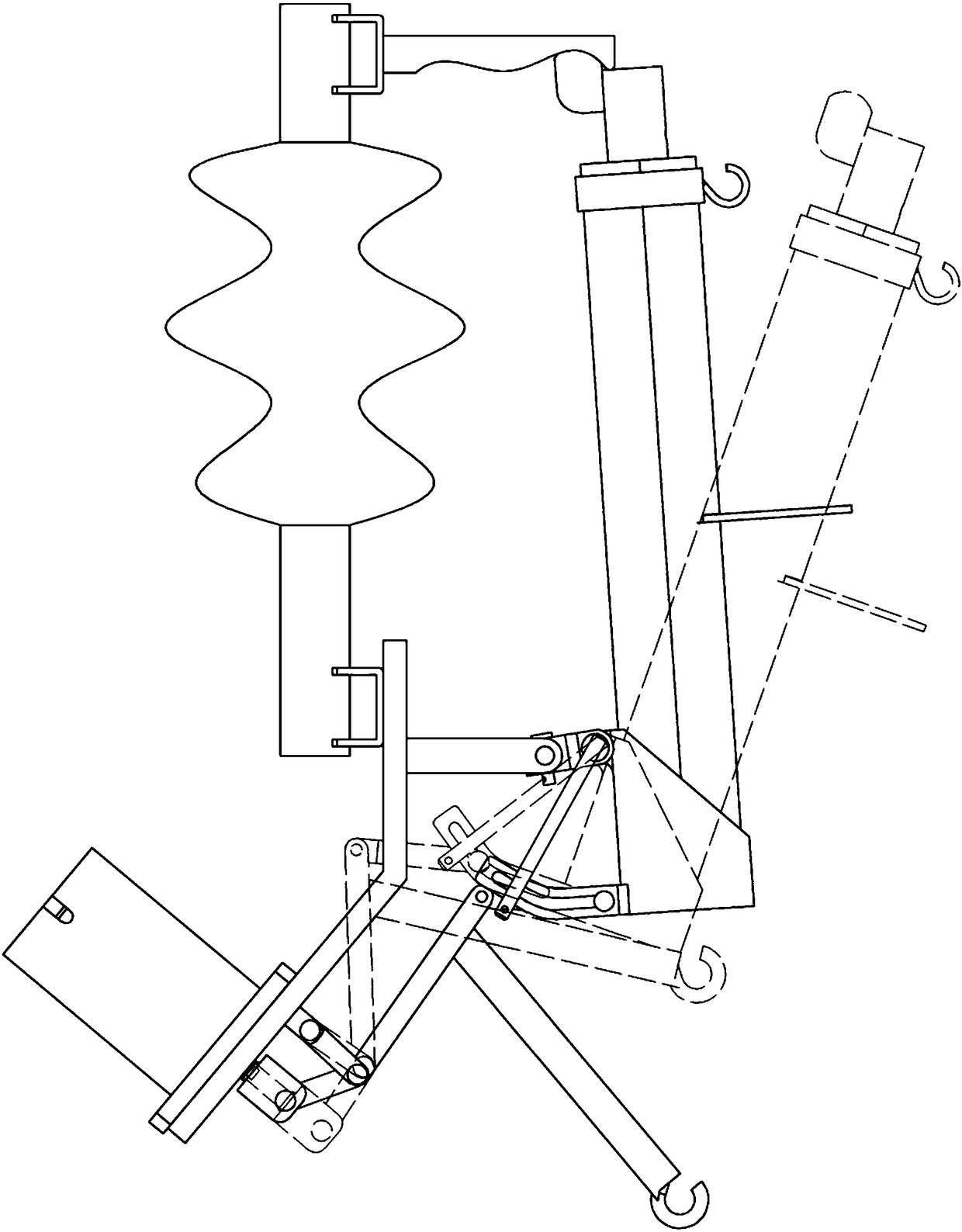

[0015] The vacuum drop switch has a drop action mechanism and a vacuum switch assembly. The drop action mechanism has a bracket 27, a first hinge seat 6, a second hinge seat 24, a crank arm 21, a first permanent magnet action mechanism 26, a base 15, a first The hinge seat, the second hinge seat, and the first permanent magnet action mechanism are installed on the bracket, and the first hinge seat is equipped with a first connecting plate 10, one end of the first connecting plate is hinged with the first hinge seat, and the other end is hinged with the upper part of the base The second hinge base is equipped with a second connecting plate 23, one end of the second connecting plate is hinged with the second hinge base, the other end is hinged with the middle part of the crank arm, and one end of the crank arm is hinged with the drive rod 25 of the first permanent magnet action mechanism , the other end of the crank arm is connected to the lower part of the base through a hinge. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com