Tubular splitter

A splitter and tube-type technology, which is applied in the field of bulk material sample shrinkage, can solve the problems of inability to install, large overall size, etc., and achieve the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and embodiments.

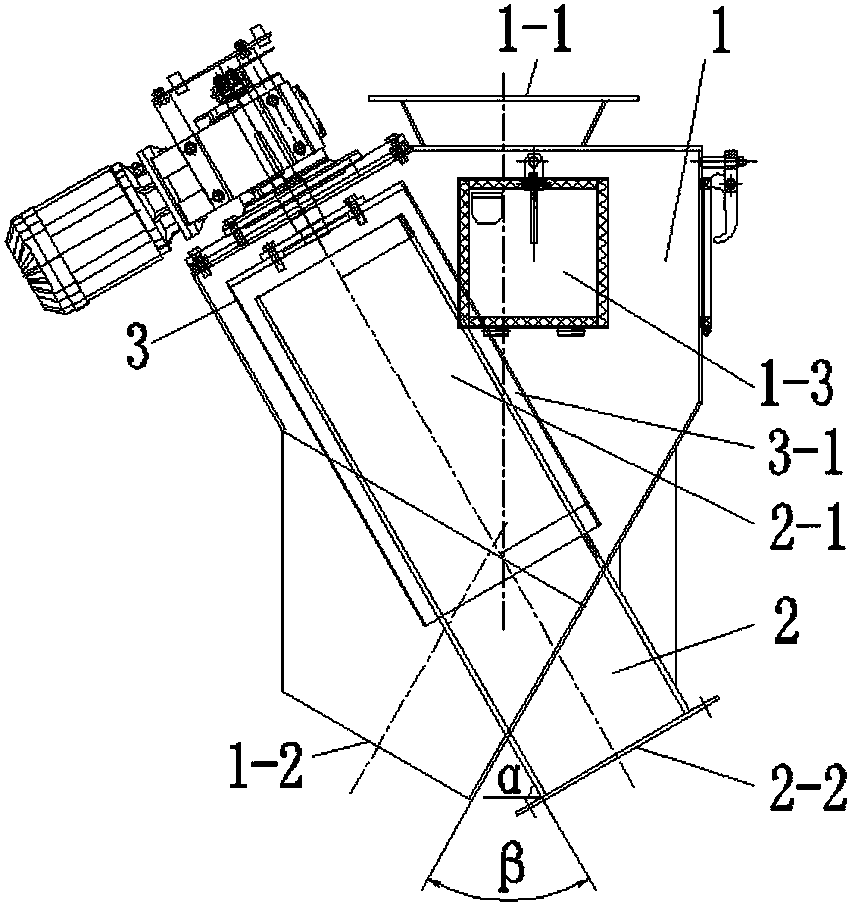

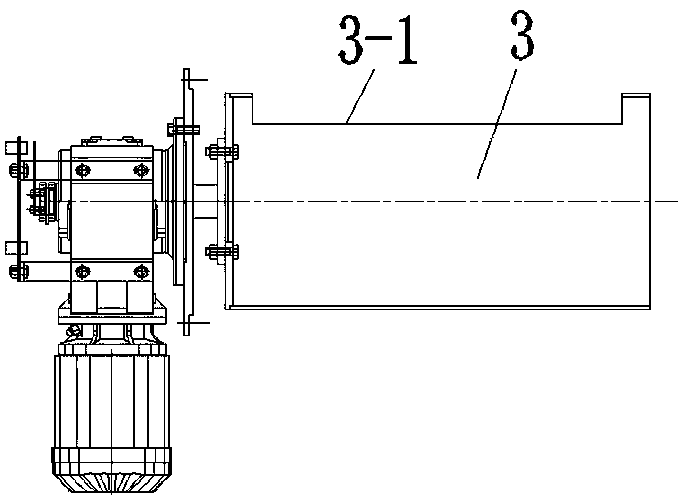

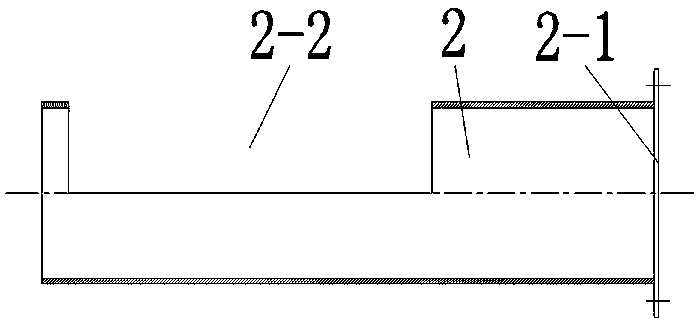

[0017] Such as figure 1 As shown, a tubular splitter includes a housing 1, a fixed tube 2 and a rotating tube 3. A feed port 1-1 is provided above the housing 1, and a sample discarding port 1-1 is provided below the housing 1. 2; the fixed pipe 2 is arranged obliquely in the housing 1, such as image 3 As shown, the outer circumference of the fixed tube 2 is provided with a gap 2-1 that allows the material to enter the tube, and the gap 2-1 faces the feed port 1-1 of the housing 1, and the sample retention port 2-2 of the fixed tube 2 is formed by The casing 1 protrudes obliquely from below; the rotating tube 3 is set on the outside of the fixed tube 2, and the outer circumference of the rotating tube 3 is provided with a shrinkage port 3-1, and the material can pass through the feed port 1-1 and the shrinkage port 3-1 , the gap 2-1 and finally discharged f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com