Industrial robot electric control cabinet inner temperature detection system

An industrial robot, internal temperature technology, applied in radiation pyrometry, instruments, measuring devices, etc., can solve the problems of small monitoring range, potential safety hazards, insufficient measurement accuracy, etc., and achieve high thermal sensitivity, high imaging speed, high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

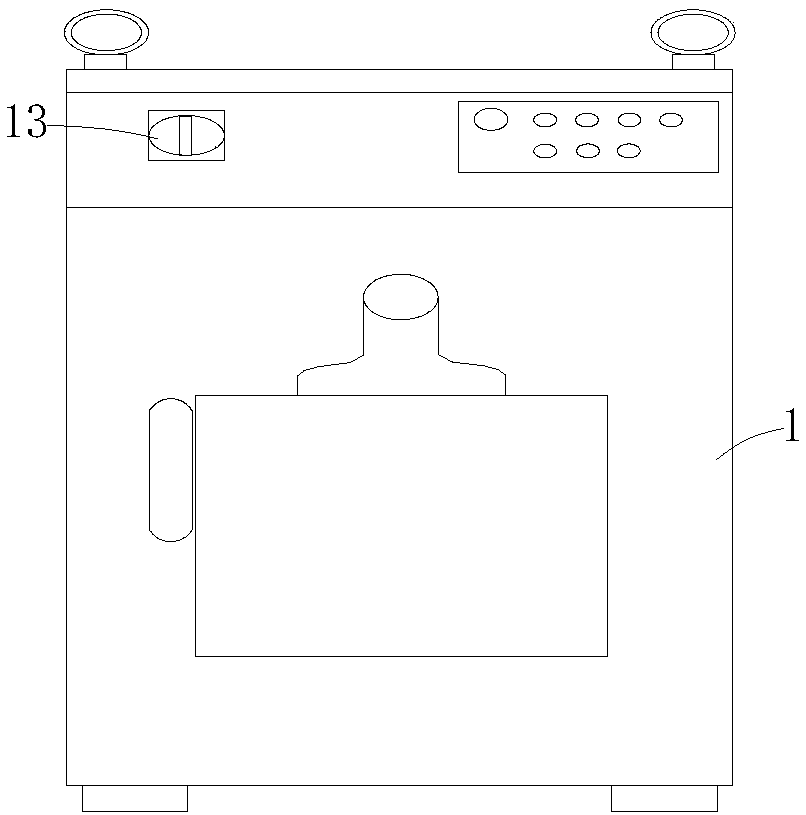

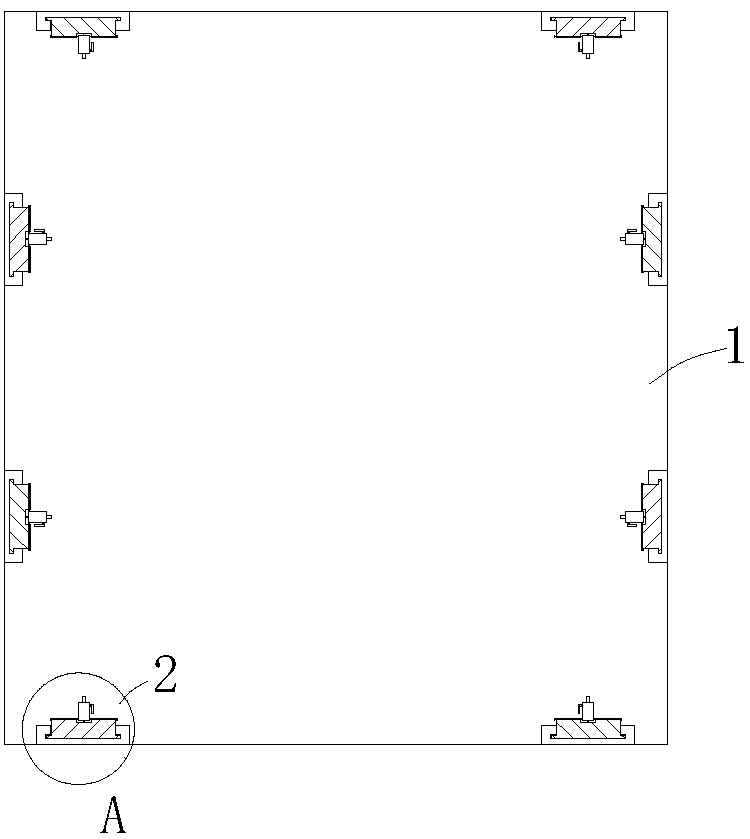

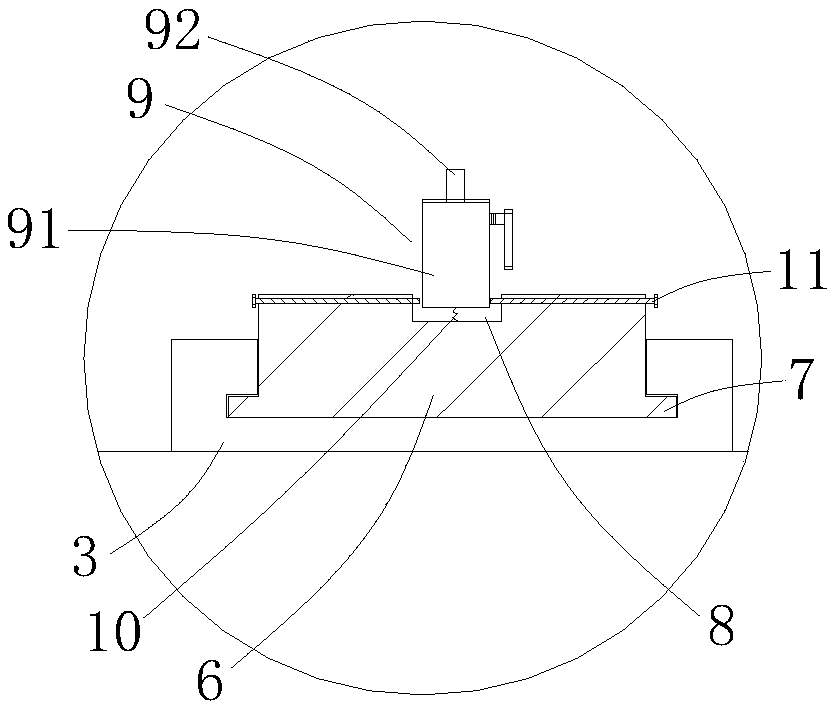

[0019] like Figure 1 to Figure 5 As shown, a temperature detection system inside the electric control cabinet of an industrial robot includes a plurality of temperature detection components 2 arranged in the electric control cabinet 1 of the robot, and the temperature detection components 2 include a rail frame 3 fixed on the inner wall of the electric control cabinet 1 of the robot , the guide rail frame 3 is provided with a guide rail groove 4, the two sides of the guide rail groove 4 are provided with a guide groove 5, and the guide rail groove 4 is provided with a sliding block 6, and the two sides of the sliding block 6 are provided with a guide plate 7, and the guide plate 7 is located at the guide In the groove 5, the top of the sliding block 6 is provided with a placement groove 8, and the placement groove 8 is provided with a thermal imaging camera 9, and the thermal imaging camera 9 includes a thermal imaging camera housing 91 and is arranged on the thermal imaging c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com