Method and device for measuring the contact surface of rotating shaft lip-shaped sealing member

A technology of lip seals and measuring devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large contact stress error and subjective feeling influence, and achieve high precision, rapid measurement of the shape and size of the contact surface, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the scope of protection of the present invention will not be limited thereby.

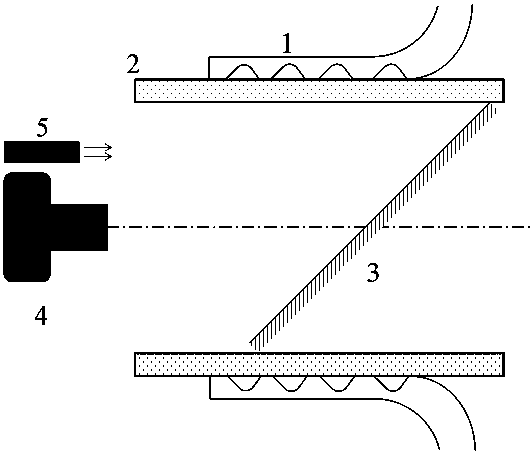

[0032] Such as figure 1 The device for measuring the contact surface of a seal includes: a seal 1 , a glass shaft 2 , a plane mirror 3 , an industrial camera 4 and a light source 5 .

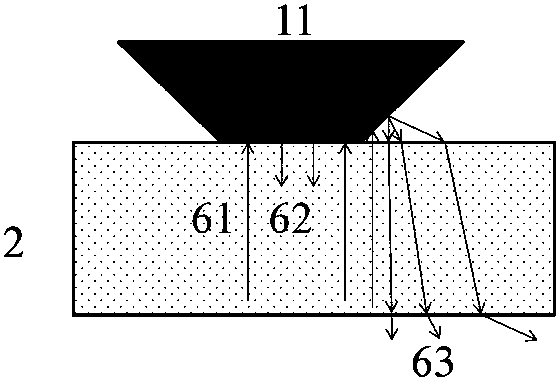

[0033] Made of rubber, PTFE or other rubber and plastic materials, the seal 1 is installed on the glass shaft 2 through interference fit, and forms a contact sealing surface with the glass shaft 2; the glass shaft 2 is made of plexiglass or other high-transmittance quartz glass materials, Its interior is a hollow structure, the wall thickness does not exceed 1mm, and the scale line for measuring length is engraved on the outer surface; the scale line is a full circle, the distance between adjacent scale lines is 1mm, and the total length of the scale line along the axis of the glass axis is 20m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com