Nuclear environment wall lamp

A technology for environment and wall lamps, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve problems such as high heat generation, high power consumption, and insufficient brightness, and achieve long life, uniform and soft light, and luminous big angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

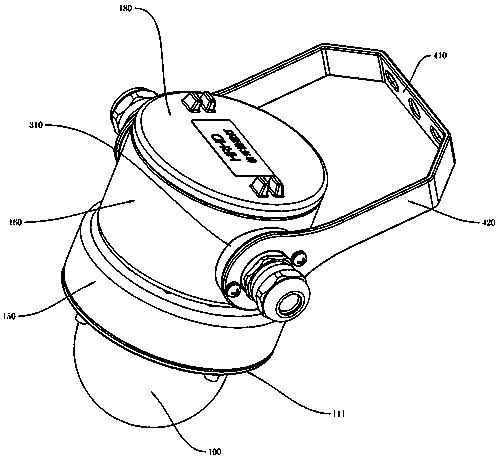

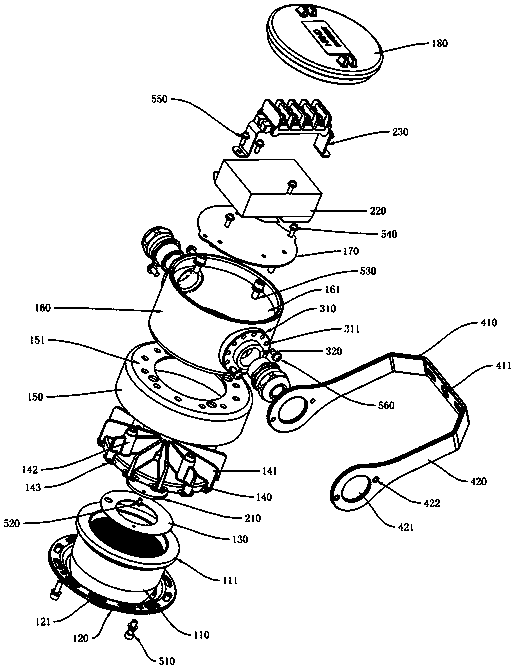

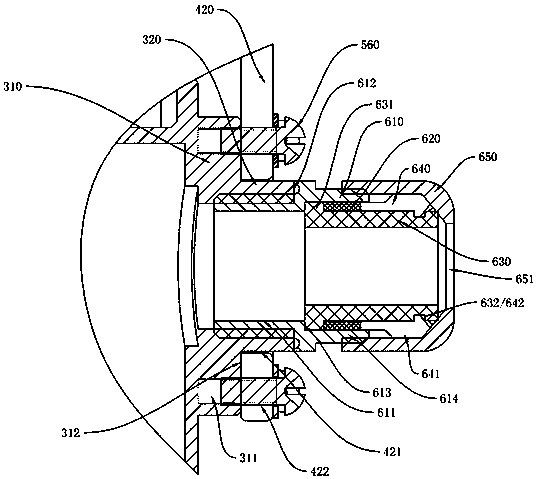

[0043] see Figure 1-Figure 7 , a nuclear environment wall lamp, comprising: a lampshade 110, the end of the lampshade 110 is provided with a clamping ring 111, and the clamping ring 111 is installed in the heat dissipation installation groove 144 of the radiator 140 and connected with the reflector 130 The closed end of the heat dissipation installation groove 144 is pressed tightly, and the end surface of the reflector 130 facing the lampshade is provided with a reflective coating, which can reflect light to the lampshade 110;

[0044] The reflective mirror 130 is provided with a reflective installation hole 131, the light source board 210 is installed in the reflective installation hole 131 and the second screw 520 is assembled and fixed with the radiator 140 after passing through the light source board 210, so that the light source board 210 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com