Variable speed drive control policy for cylindrical rotor blade of vertical axis wind turbine

A technology of rotor blades and variable speed drive, which is applied in the control of wind turbines, wind turbines at right angles to the wind direction, engine control, etc., and can solve the problems of large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention provide a variable speed drive control strategy for rotor blades of a vertical axis wind turbine.

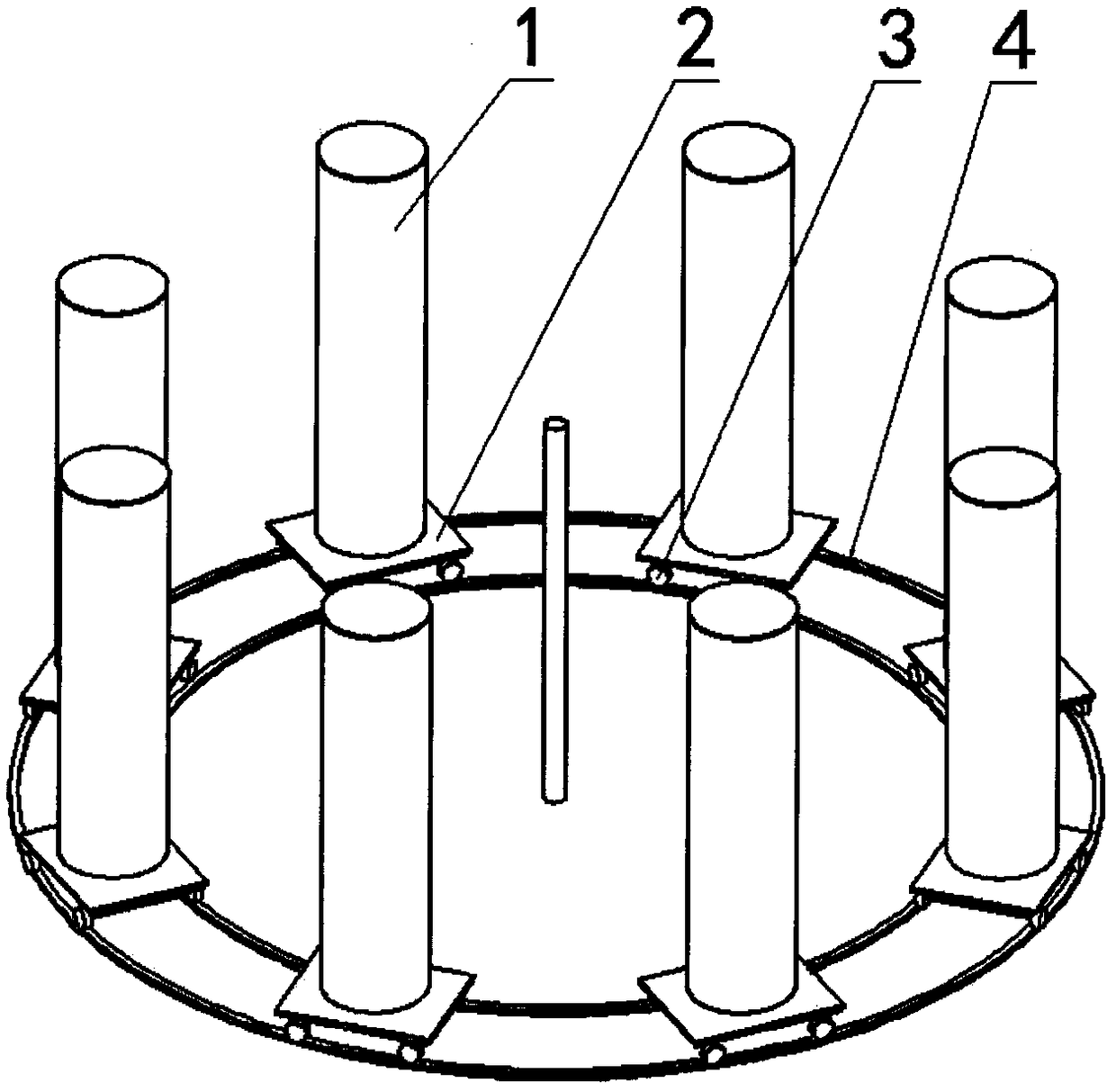

[0056] exist figure 1 In the Magnus effect vertical axis wheel-rail wind turbine shown, the prime mover driving the rotor blades is changed to a variable frequency drive synchronous motor (or a variable frequency drive asynchronous motor, but its instantaneous actual speed must be understood as equal to this Invented variable frequency drive frequency), the output shaft of the motor is directly connected to the rotor blade shaft (or connected after deceleration through a reducer with a transmission ratio of i).

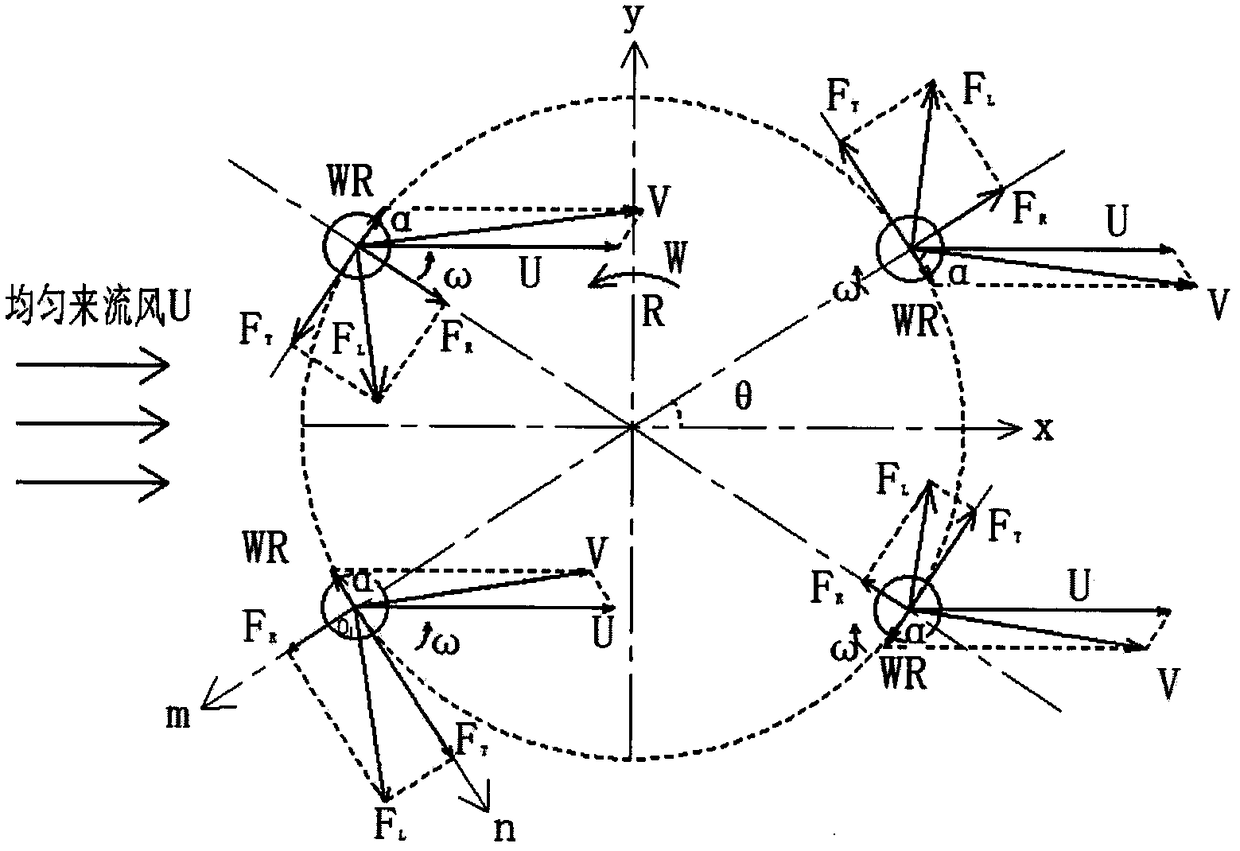

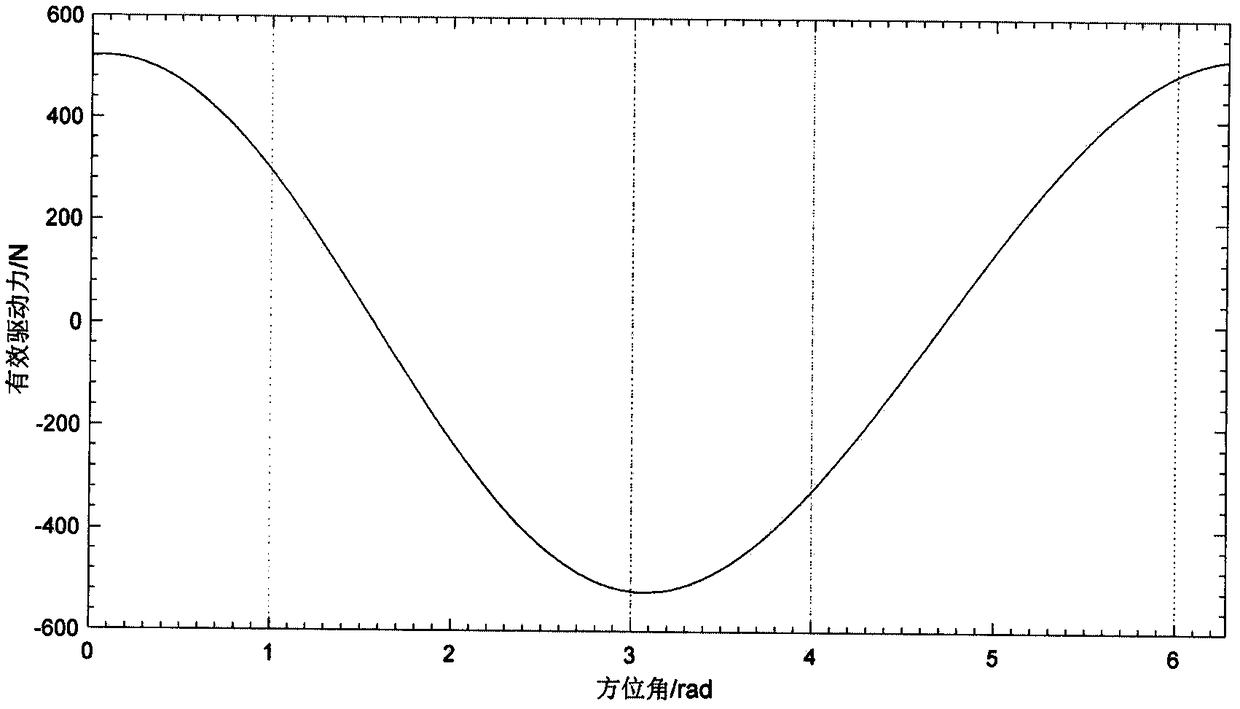

[0057] Set the working parameters of the wind turbine as follows: the radius of the cylindrical rotor blade r=0.5m, the height of the cylindrical blade h=4m, the radius of the circular orbit R=5m, and the revolution angular velocity of the cylindrical blade W=(π / 30)rad / s when the wind turbine is in normal operation ; and assu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com