Gently-inclined broken thin lode medium-depth hole mining method

A mining method and thin vein technology, which is applied in the field of medium and deep hole mining with gently inclined and broken thin veins, to achieve the effects of simplifying the mining process, improving the efficiency of transportation, and ensuring the safety of construction personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

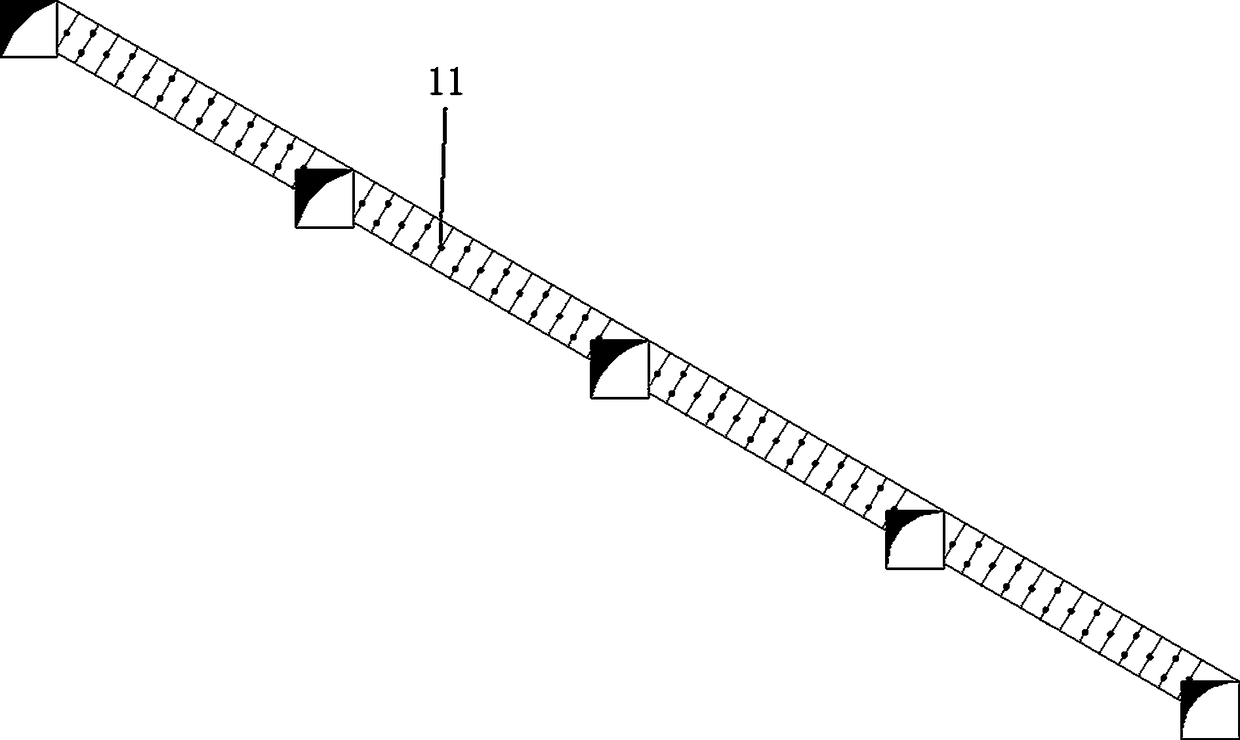

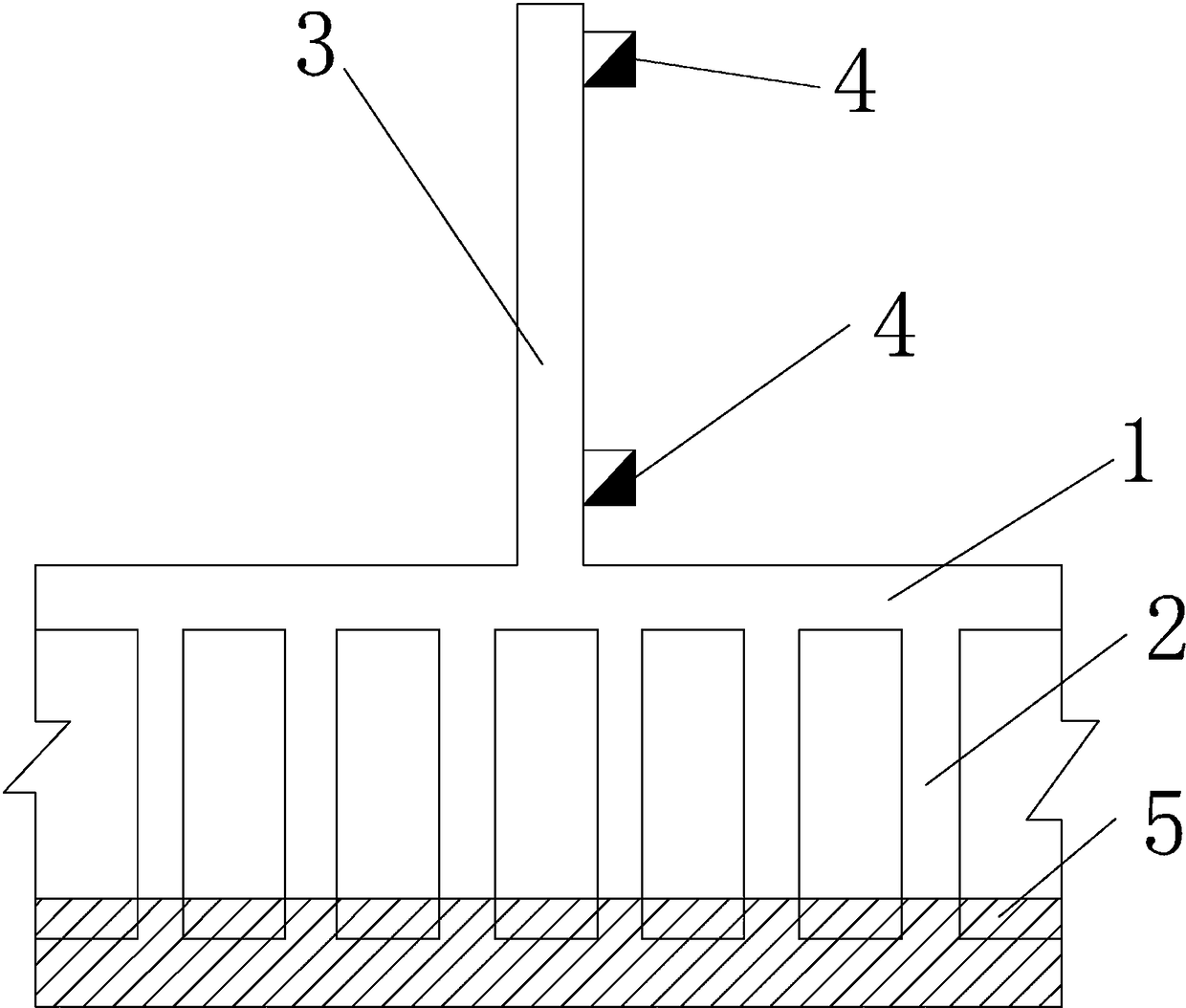

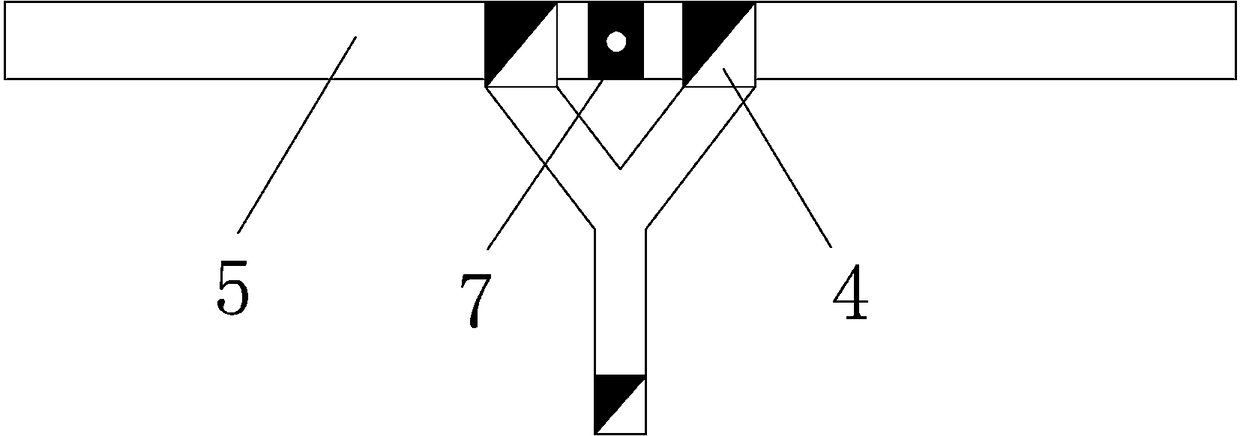

[0024] Embodiment 1: as Figure 1 to Figure 5 As shown, taking the mining of a gold mine with gently inclined broken thin veins as an example, the inclination angle of the ore body 9 is 20°-40°, the thickness of the ore body 9 is 0.5m-2.5m, and the ore grade is 3g / t-4g / t. The rocks in the hanging wall of ore body 9 are relatively broken, the hanging wall joints and fissures are developed, and the hanging wall boundary has obvious bedding planes. The ore has no spontaneous combustion and agglomeration, and belongs to a typical gently inclined broken thin vein.

[0025] (1) Division of mine pillars:

[0026] In the stope of this process, mine houses and ore pillars 10 are alternately arranged, and intermittent regular ore pillars 10 are left to support the goaf when returning to the mine house. In the mining area, calculated according to the ore body 9 dip angle of 30°, the mining area is 80m long; along the ore body 9 dip, the mining area is divided into 5 sections with a sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com