A sound insulation door structure for noise control

一种隔声门、噪声的技术,应用在隔音门/窗、门扇、翼扇的布置等方向,能够解决影响隔音效果、开关门费力、胶圈磨损等问题,达到提高隔音效果、减少磨损、延长使用寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

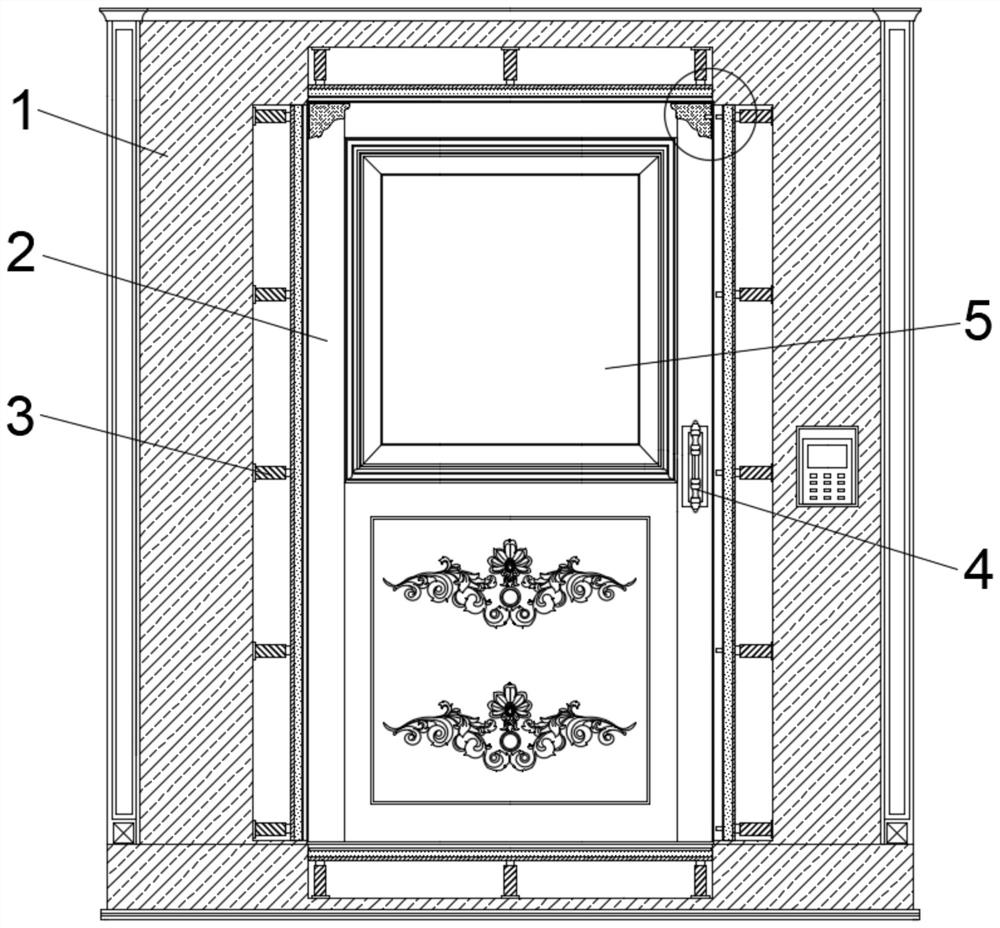

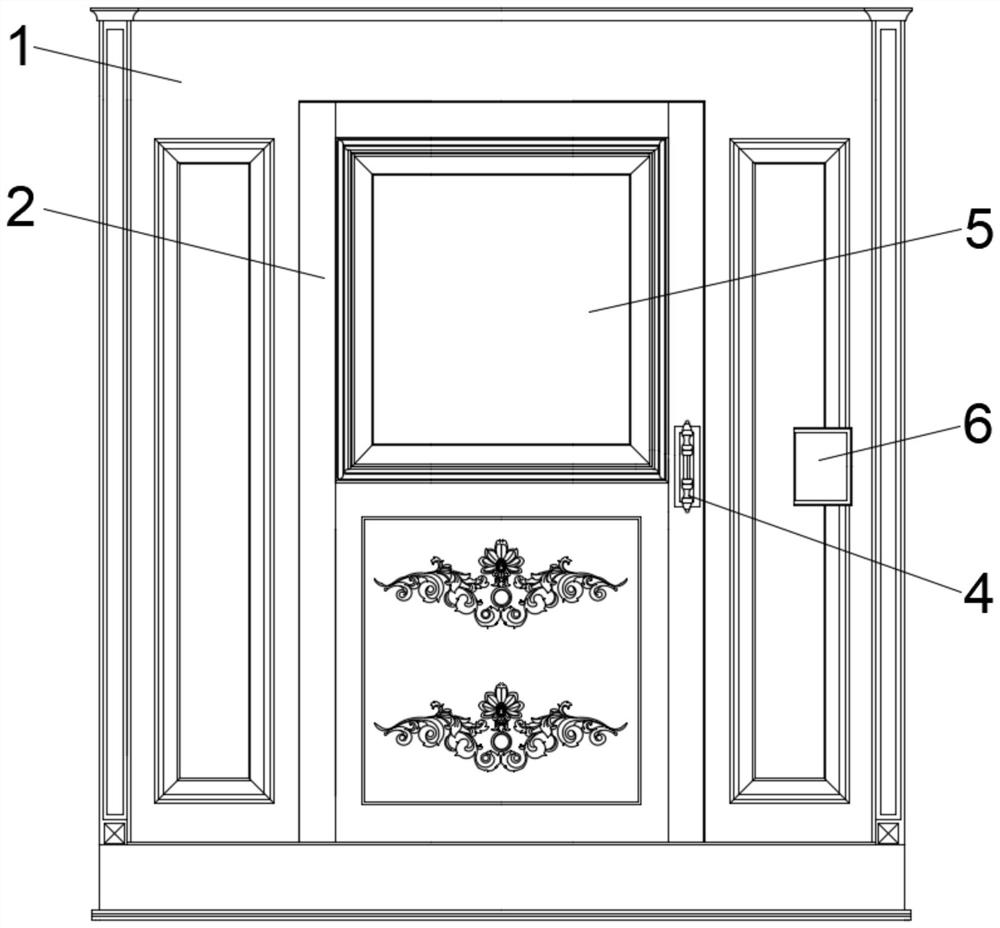

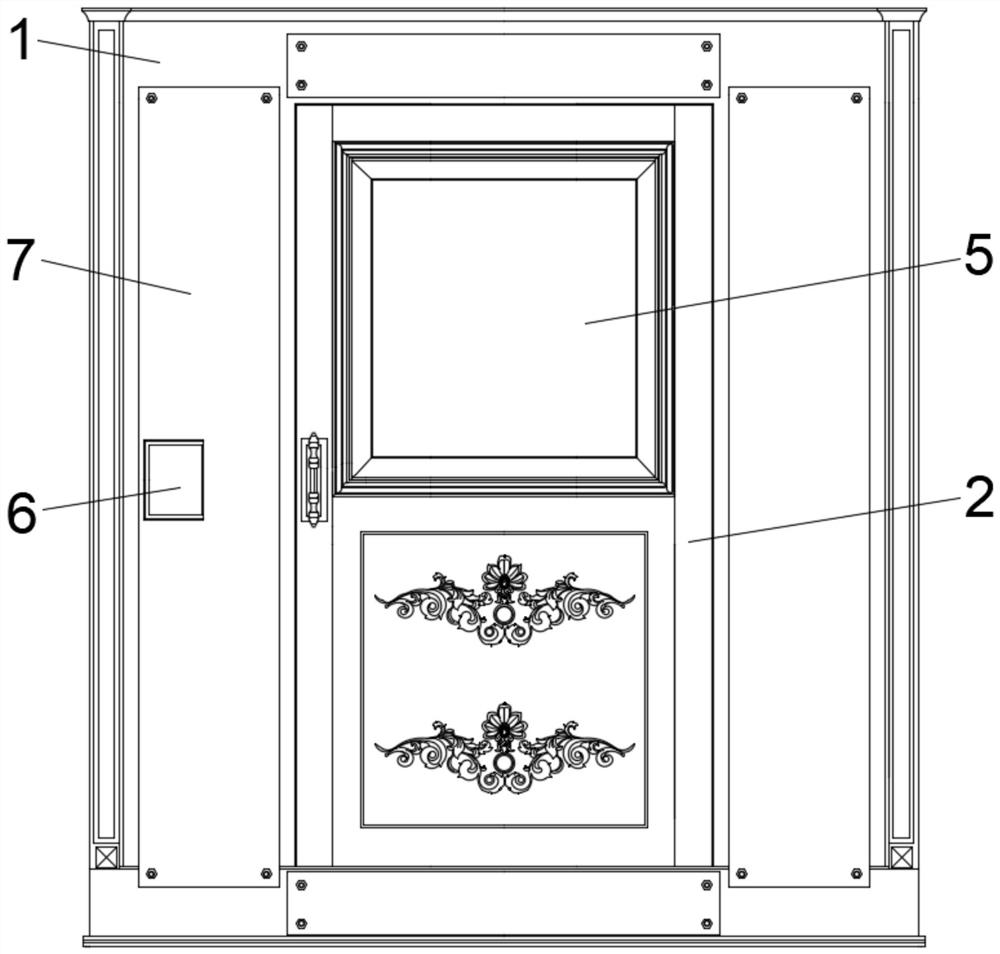

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The present invention provides a sound-insulating door structure for noise control, including a door frame 1, a main door body 2, sound-absorbing cotton 201, PU202, a mineral wool sound-insulating board 203, an electric push rod 3, a door handle 4, a sound-insulating glass 5, a control Switch 6, maintenance cover plate 7, support steel plate 8, soundproof felt strip 9, clip strip 10 and lock block 11;

[0036] A main door body 2 is installed on the inner side of the door frame 1 through a rotating shaft; the main door body 2 is composed of two layers of sound-absorbing cotton 201, two layers of PU202 and one layer of mineral wool sound insulation board 203; the inner side of the main door body 2 is also fixedly installed with A piece of soundproof glass 5; the front and rear sides of the main door 2 are also fixed with a door handle 4; the inner side of the door frame 1 and the inner side of the top and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com