Cast-in-situ concrete construction method of folding-type roof

A construction method and technology of concrete, applied to roofs, building components, buildings, etc., to achieve the effect of smooth concrete construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Such as Figure 12 As shown, the folded roof cast-in-place concrete construction method of the present invention, the main construction steps and technical control points are:

[0038] 1) Positioning elevation control:

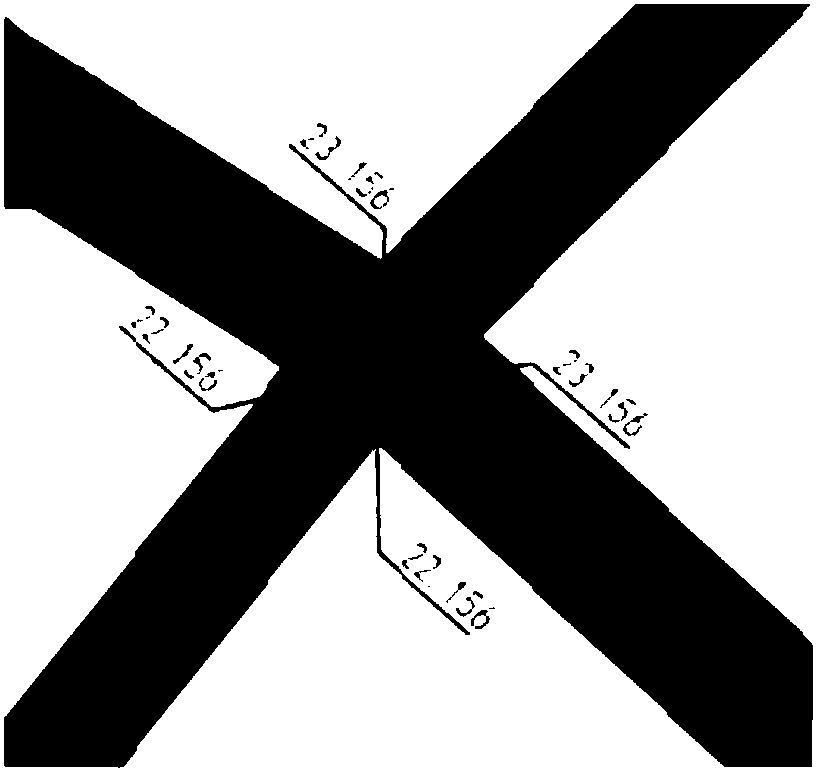

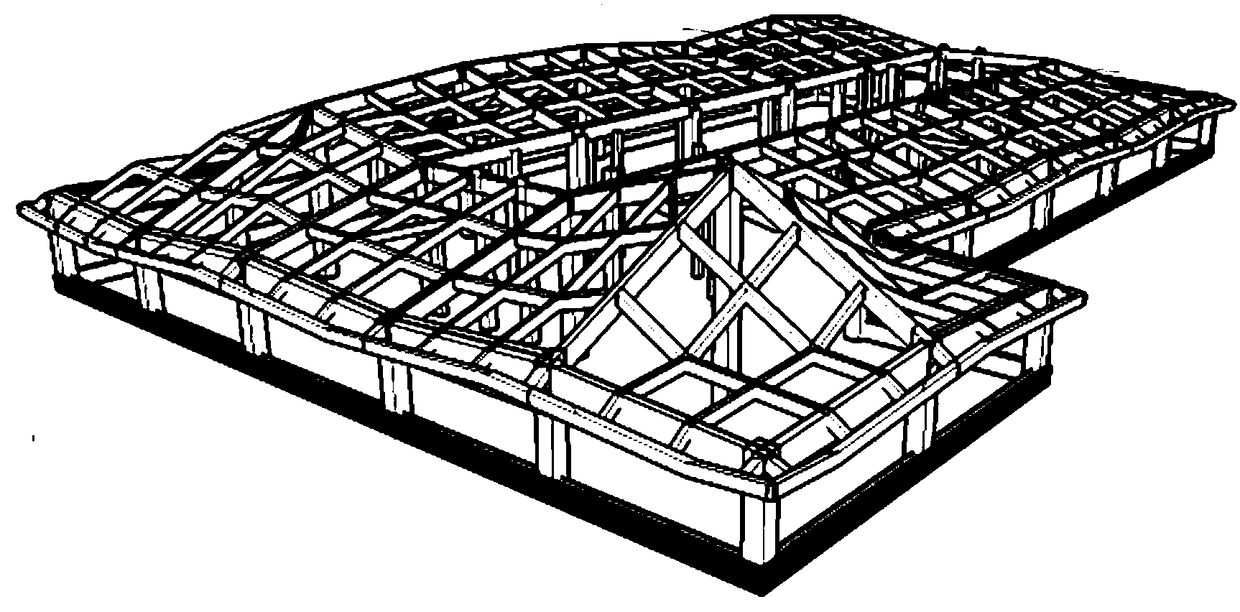

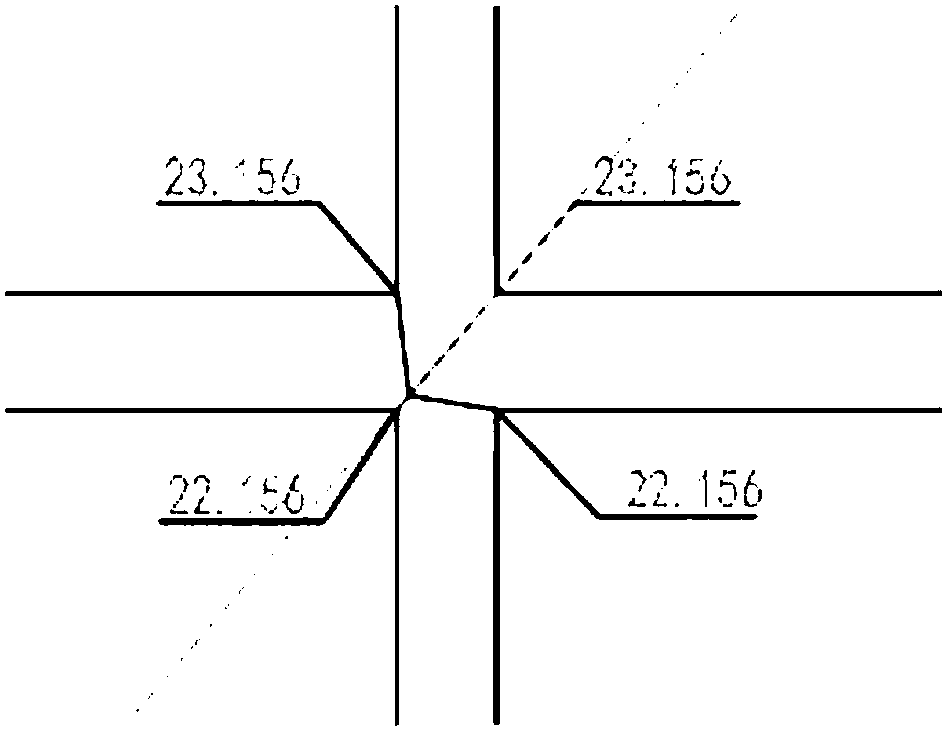

[0039] (1) Roof girders and slabs are all slopes, the angle changes greatly, and there are many slopes in the formwork configuration, it is difficult to locate the oblique elevation of beams and slabs. Through detailed design and BIM technology, 3D modeling ( figure 2 , 3), in the 3D model, mark the elevation values of all the beam and slab intersection points of the sloping roof, so as to solve the difficult problem of locating the oblique elevation of the beam and slab.

[0040](2) The erection height of inclined roof bent frames varies greatly, and it is difficult to control the elevation. According to the three-dimensional model drawings and marked elevations, conduct on-site review calculations, uniformly prepare a 1-meter elevation control l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com