A method for improving the air permeability of a sintered material layer and a device for distributing balls

A gas-permeable, sintered material technology, applied in the field of iron and steel metallurgy, which can solve the problems of over-melting and high local temperature of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

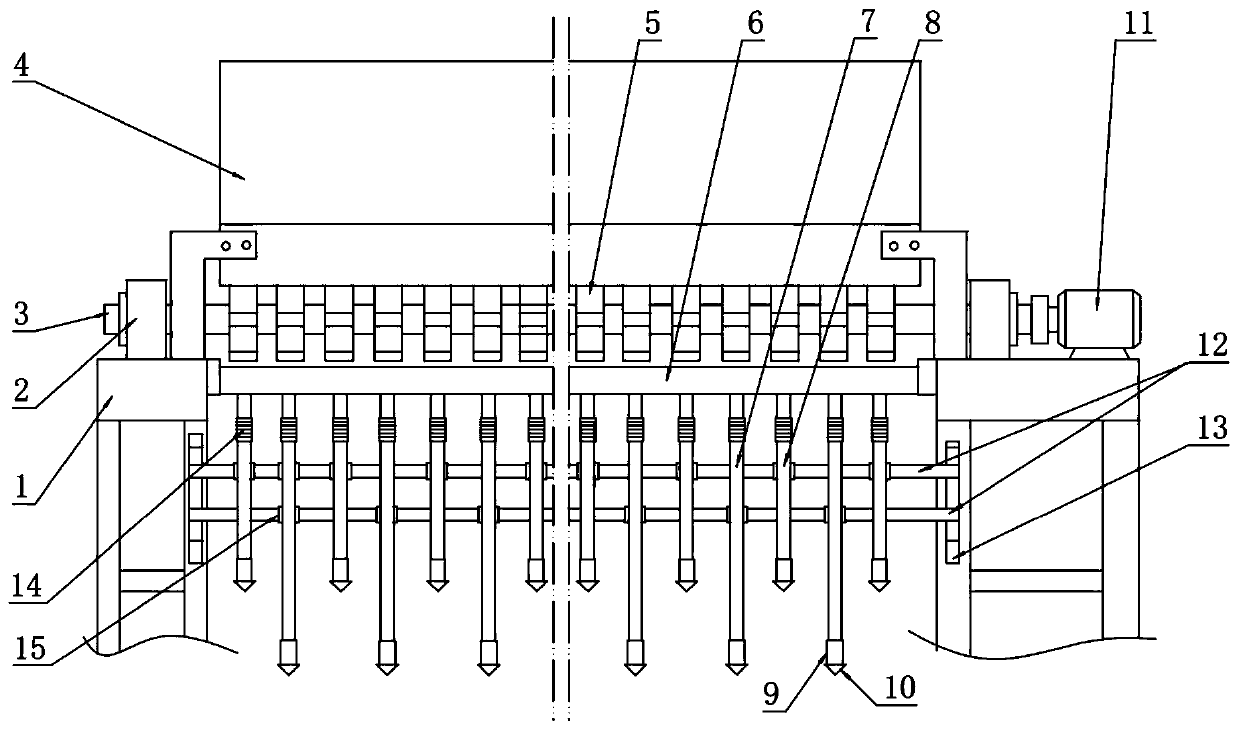

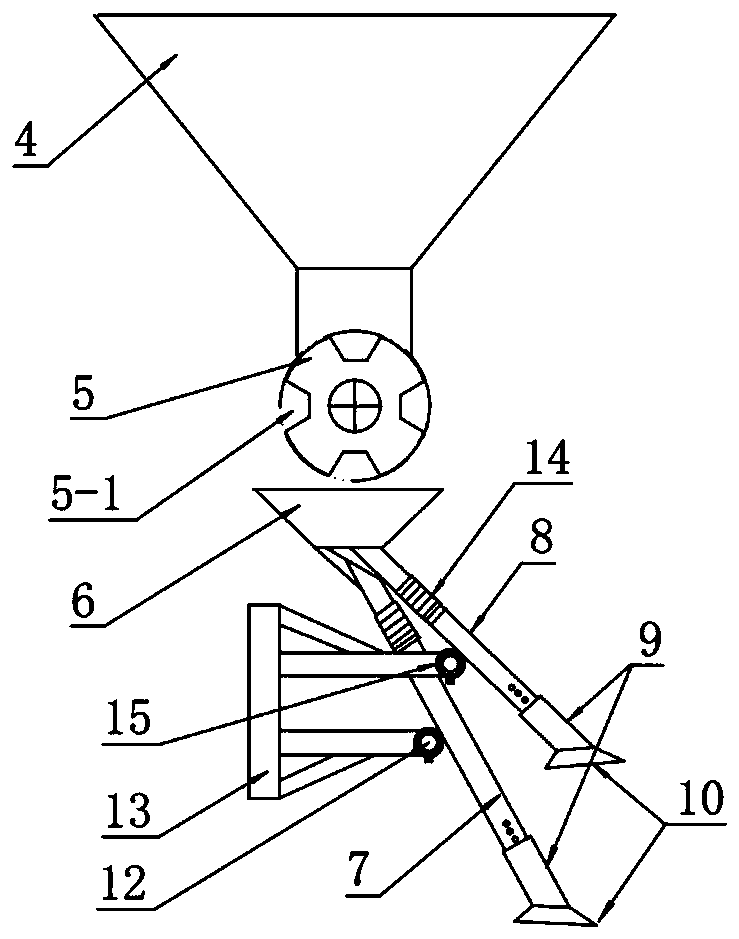

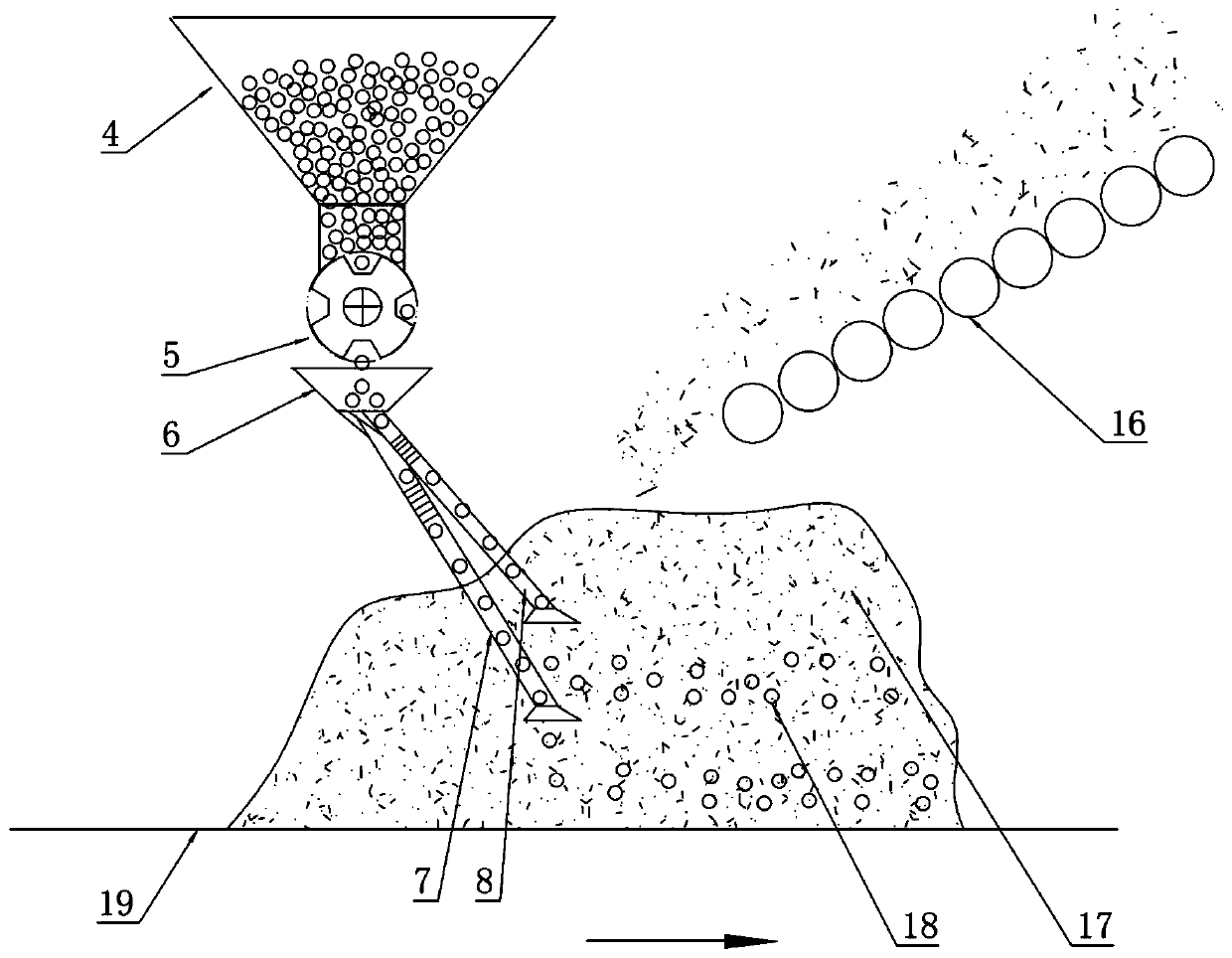

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The raw material ratio of air-permeable particles is as follows: 50% sawdust, 4% slaked lime powder, and the balance is iron ore powder. Mix the above-mentioned raw materials evenly, and make them into spherical bodies with a diameter of 8-10 mm through a granulator, and sieve out the slag and send them to the silo for standby. The air-permeable particles mentioned above are added to the sintered material, and the addition ratio is controlled at 1.5% of the total amount of the sintered material. The sintering parameters are as follows: negative pressure (-kPa) 13.2, vertical sintering speed (m / min) 0.03044, horizontal sintering speed (m / min) 1.607, sinter drum index (%) 77.33, RDI +3.15 (%) 81.36, 10% (°C) 1183 reflow reduction under load, 40% (°C) 1289 reflow reduction under load.

Embodiment 2

[0028] Embodiment 2: The raw material ratio of air-permeable particles is as follows: 50% sawdust, 5% slaked lime powder, and the balance is iron ore powder. Mix the above-mentioned raw materials evenly, and make them into spherical bodies with a diameter of 8-10 mm through a granulator, and sieve out the slag and send them to the silo for standby. The air-permeable particles mentioned above are added to the sintered material, and the addition ratio is controlled at 2.5% of the total amount of the sintered material. The sintering parameters are as follows: negative pressure (-kPa) 12.7, vertical sintering speed (m / min) 0.03055, horizontal sintering speed (m / min) 1.619, sinter drum index (%) 78.33, RDI +3.15 (%) 82.47, 10% (°C) 1197 reflow reduction under load, 40% (°C) 1328 reflow reduction under load.

Embodiment 3

[0029] Embodiment 3: The raw material ratio of air-permeable particles is as follows: 50% sawdust, 4.5% slaked lime powder, and the balance is iron ore powder. Mix the above-mentioned raw materials evenly, and make them into spherical bodies with a diameter of 8-10 mm through a granulator, and sieve out the slag and send them to the silo for standby. The air-permeable particles mentioned above are added to the sintered material, and the addition ratio is controlled at 2.0% of the total amount of the sintered material. The sintering parameters are as follows: negative pressure (-kPa) 12.8, vertical sintering speed (m / min) 0.03053, horizontal sintering speed (m / min) 1.618, sinter drum index (%) 76.67, RDI +3.15 (%) 81.36, 10% (°C) 1192 reflow reduction under load, 40% (°C) 1294 reflow reduction under load.

[0030] Sampling the test data obtained by the method of the present invention and the operation data comparison of the existing method are shown in the table below.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com