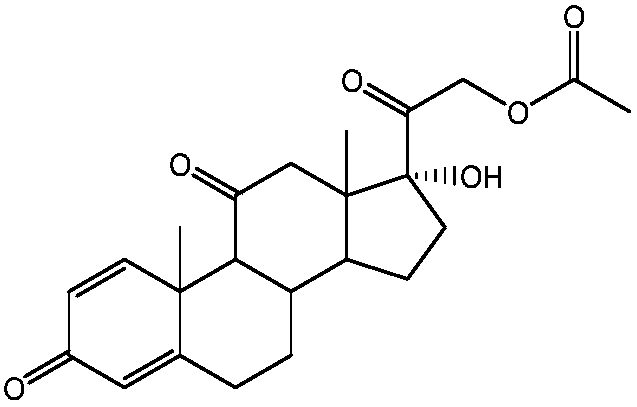

Method for preparing prednisone acetate

A technology of prednisone acetate and cortisone acetate, which is applied in the field of chemical preparation, can solve the problems of environmental and personnel health threats, unstudied size, and low conversion rate, and achieves low toxicity, easy to obtain and simple solvent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Make first-class seeds of simple Arthrobacter CPCC 140451, put them into a 50L fermenter with 30L of liquid in the fermenter, feed 1.8Kg after culturing at 28°C for 12-14h, control the speed at 200rpm, transform at a temperature of 32-34°C, and transform for 40h After that, inactivate and centrifuge, collect the solid part, and extract with acetone to obtain 1.75Kg of prednisone acetate crude product. Put the crude prednisone acetate into a 50L refining tank, add 30L chloroform, reflux and dissolve, slowly pour into 2.7L acetone, concentrate under reduced pressure to a volume of 3-5L, cool down to 0-5°C, keep warm for 2 hours and then centrifuge , collect fine work, put fine work in 85 ℃ of hot air dryings and place 48h, obtain the prednisone acetate fine work of 1.45Kg, fine work one-time weight yield is 80.56%, the external standard of fine work is 98.52%, impurity 1 prednisone and impurity 2 can be Pine was not detected, and all the other indicators met the quality r...

Embodiment 2

[0024] Make first-class seeds of simple Arthrobacter CPCC 140451, put them into a 50L fermenter with 30L of liquid in the fermenter, feed 1.5Kg after culturing at 30°C for 12-13h, control the speed at 250rpm, and transform at a temperature of 32-34°C for 36h after transforming , inactivate and centrifuge, collect the solid part, extract with acetone to obtain 1.44Kg of the crude product of prednisone acetate, put the crude product into a 50L refining tank, add 25L of dichloromethane, slowly flush into 1.5L of ethanol after dissolving, and concentrate under reduced pressure to After a volume of 4-5L, cool down to 0-5°C, centrifuge after heat preservation and crystallization for 2 hours, collect the fine product, dry the fine product with hot air at 85°C for 48 hours, and obtain 1.24Kg of the fine product of prednisone acetate, and the yield of the fine product is 82.67%. The external standard of the high-quality goods is 98.74%, the impurity 1 prednisone and the impurity 2 corti...

Embodiment 3

[0026] Make first-class seeds of simple Arthrobacter CPCC 140451, put them into a 50L fermenter with 30L of fermentation tank liquid, feed 2.1Kg after culturing at 30°C for 12-13h, control the speed at 300rpm, transform at a temperature of 32-34°C, transform for 45h After inactivation, the solid part was collected by centrifugation, extracted with acetone to obtain 2.05Kg of crude product, 40L chloroform was added to the dried crude product, and 2.5L cyclohexane was slowly poured into the dried crude product, after being concentrated under reduced pressure to a volume of 5-6L, the temperature was lowered Centrifuge at 0-5°C, heat preservation and crystallization for 2 hours, collect the fine product, dry the fine product at 85°C with hot air for 48 hours, and obtain 1.66Kg of prednisone acetate fine product, the primary weight yield of the fine product is 79.05%, and the external standard of the fine product is 98.56%. Impurity 1 prednisone and impurity 2 cortisone were not det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com