Lubricating organic-silicon anti-icing coating prepared by ''one-step method'' and preparation method of coating

A lubricity, anti-icing technology, applied in the coating and other directions, to achieve the effects of reduced adhesion, low shear modulus, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

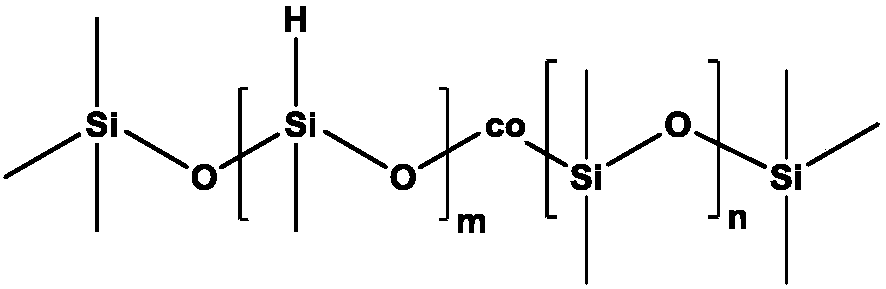

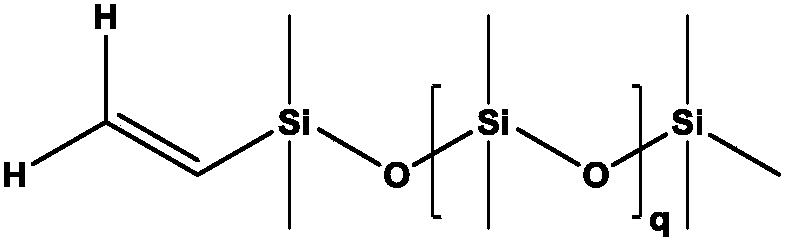

[0042] 2.0g main chain PDMS-PMHS (molecular weight is 120000), 2.0g branched chain PDMS-V (molecular weight is 3750), 2.0g cross-linking agent V-PDMS-V (molecular weight is 12500), 1.5g did not participate in the cross-linking reaction The additive PDMS (molecular weight is 17500) and 42.5g xylenes are formulated into the solution that solute mass percentage content is 15wt%, add the xylene solution (solution mass fraction is 5.0wt%) of the Karstedt's catalyst of 100 μ L, ultrasonic stirring 1.5h with Mix evenly to make the solution uniform and transparent; take an appropriate amount of the solution and drop-coat it on the surface of the substrate, and let it dry for 2.5 hours at room temperature, and then put it in a blast drying oven at 110°C for 4.5 hours to cross-link and solidify to form a film, " One-step method" to prepare lubricating silicone anti-icing coating.

[0043] The measured static water contact angle of the coating is 100°, and the ice shear strength is 11.6k...

Embodiment 2

[0045] 2.0g main chain PDMS-PMHS (molecular weight is 120000), 2.0g branched chain PDMS-V (molecular weight is 7000), 1.0g crosslinking agent V-PDMS-V (molecular weight is 20000), 1.0g did not participate in the crosslinking reaction The additive PDMS (molecular weight is 15000) and 4.0g chloroform are formulated into the solution that solute mass percentage content is 60wt%, add the chloroform solution (solution mass fraction is 2.5wt%) of Karstedt's catalyst of 46 μ L, ultrasonic stirring 2h Mix evenly to make the solution uniform and transparent; take an appropriate amount of solution and spray it on the surface of the substrate, let it dry at room temperature for 1 hour, and then put it into a blast drying oven at 85°C for 3 hours to cross-link and solidify to form a film, "one-step method "Preparation of lubricious silicone anti-icing coatings.

[0046] The measured static water contact angle of the coating is 97°, and the ice shear strength is 8.4kPa.

Embodiment 3

[0048] 6.0g main chain PDMS-PMHS (molecular weight is 8000), 6.0g branched chain PDMS-V (molecular weight is 500), 3.5g crosslinking agent V-PDMS-V (molecular weight is 5000), 3.25g did not participate in crosslinking reaction The additive PDMS (molecular weight is 532) and 31.25g tetrahydrofuran are prepared into a solution with a solute mass percentage of 37.5wt%, and 200 μL of Karstedt's catalyst tetrahydrofuran solution (solution mass fraction is 3.0wt%) is added, and ultrasonically stirred for 1 h to mix uniformly , to make the solution uniform and transparent; take an appropriate amount of the solution and spin-coat it on the surface of the substrate, and let it dry for 3 hours at room temperature, and then put it into a blast drying oven at 60°C for 3 hours to cross-link and solidify to form a film, "one-step" preparation Lubricious silicone anti-icing coating.

[0049] The measured static water contact angle of the coating is 100°, and the ice shear strength is 14.8kPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com