Method of fermenting organic fertilizer with chicken manure

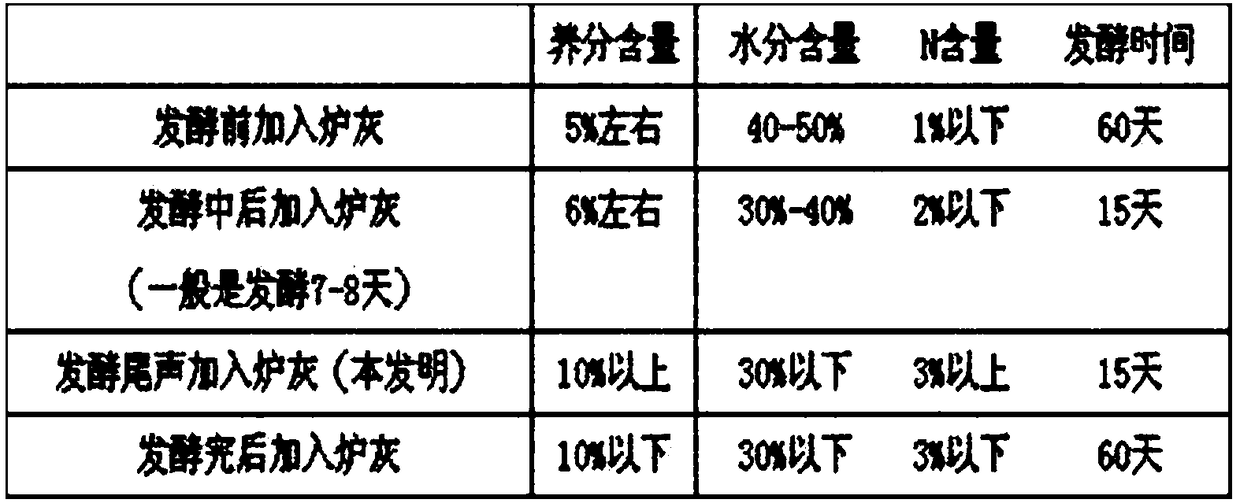

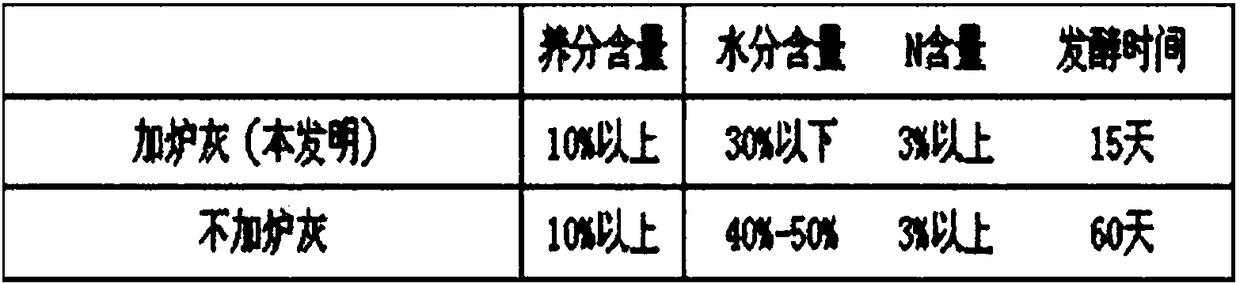

A technology of organic fertilizer and chicken manure, which is applied in the preparation of organic fertilizer, organic fertilizer, inorganic fertilizer, etc., can solve the problems of low nutrient content of organic fertilizer, high cost of organic fertilizer, loss of nitrogen nutrient, etc., to reduce water content, Effect of increasing fertilizer efficiency and inhibiting fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: the method for fermenting organic fertilizer with feces of southern laying hens, comprises the steps:

[0014] (1) Mix fresh free-range dry chicken manure with a water content of about 12% and fresh caged chicken manure with a water content of more than 90% to prepare chicken manure with a water content of 60%-70% for subsequent use. Wherein, the amount of free-range dry chicken manure and cage-raised dilute chicken manure is based on the mixed chicken manure with a water content of 60%-70%;

[0015] (2) Initial fermentation: adding zeolite powder and calcium chloride to chicken manure with a water content of 60%-70%, wherein the weight of chicken manure, zeolite powder and calcium chloride with a water content of 60%-70% The ratio is 100:3:3, and the rw fermentation agent is added, stirred and mixed evenly, and then fermented at a temperature of 70°C for about 10 days to obtain the initial fermentation material; the rw fermentation agent is purchased dire...

Embodiment 2

[0017] Embodiment 2: the method for fermenting organic fertilizer with manure of southern laying hens, comprises the steps:

[0018] (1) Mix fresh free-range dry chicken manure with a water content of about 12% and cage-raised thin chicken manure with a water content of more than 90% to prepare chicken manure with a water content of 60%-70% for subsequent use, wherein The amount of free-range dry chicken manure and cage-raised dilute chicken manure is subject to mixing to obtain chicken manure with a water content of 60%-70%;

[0019] (2) Primary fermentation: adding zeolite powder and calcium chloride to fresh chicken manure with a water content of 60%-70%, wherein the water content is 60%-70% chicken manure, zeolite powder, and calcium chloride The weight ratio is 100:3:3, and the rw fermentation agent is added, stirred and mixed evenly, and then fermented at a temperature of 60°C for about 10 days to obtain the primary fermentation material;

[0020] (3) Final fermentation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com