Powder conveying device

A technology for conveying devices and powders, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., and can solve problems such as difficult implementation, decreased measurement accuracy of measuring instruments, and wear and tear of measuring instruments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

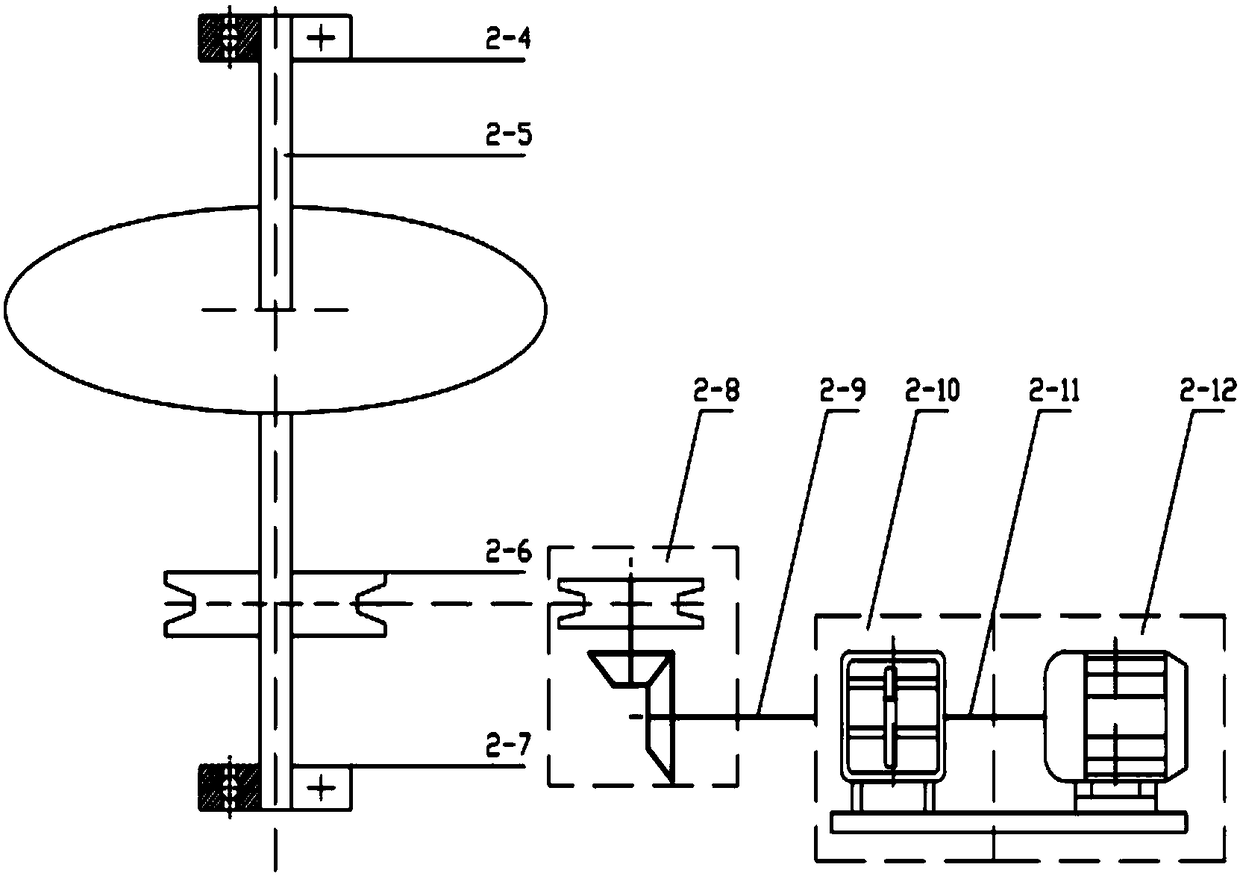

[0039] specific implementation plan

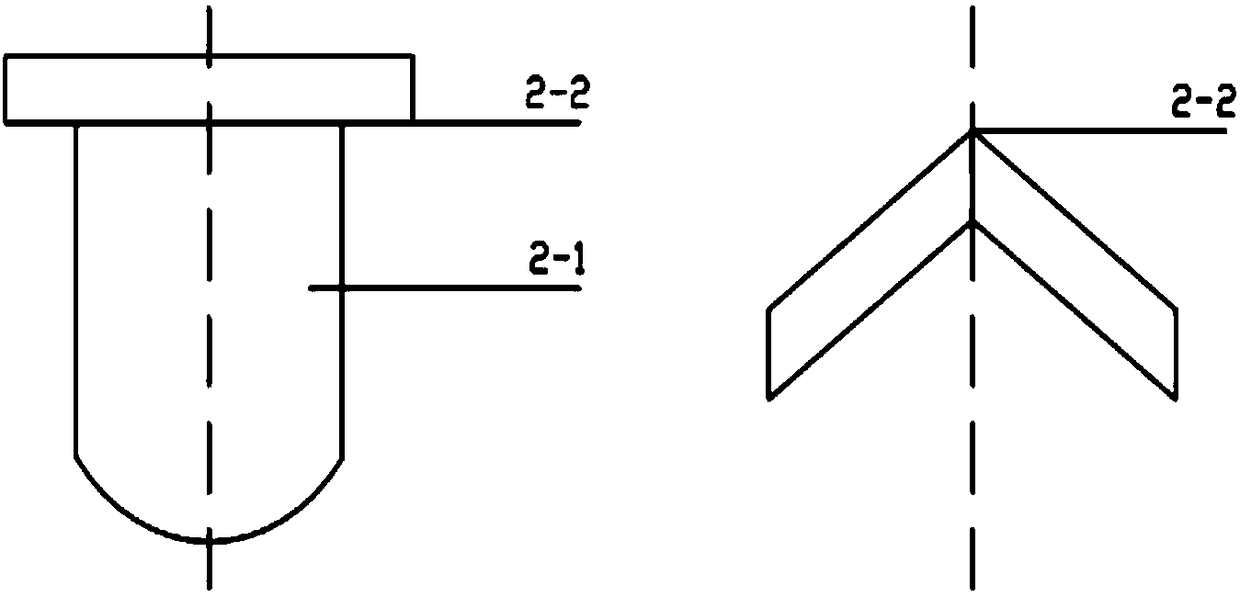

[0040] According to the needs of the working conditions, the appropriate vibration drop and the rotation speed of the U-shaped groove can be calculated in advance, and the appropriate distribution gas pressure (ie, high-pressure delivery gas pressure) can be set according to the needs of subsequent devices. Fill the silo (1-1) with the conveyable powder described in the invention, start the vibrating screen (1-3) and the motor (2-12) at the same time after the feeding is completed, and set the appropriate vibration drop according to the working conditions Volume and rotation speed (U-shaped groove (2-1)), after the device runs stably (that is, the U-shaped groove is fully loaded), turn on the high-pressure gas with a pre-set flow rate and start conveying.

[0041]In the powder delivery device of the present invention, the vibrating sieve (1-3) shakes off the powder from the silo (1-1), the U-shaped groove (2-1) holds the powder, and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com