Grain clearing and automatic sorted storage integrated system

An automatic classification and grain technology, applied in the direction of loading/unloading, conveyors, mechanical conveyors, etc., can solve the problems of high labor intensity, low manual operation accuracy, mechanical damage, etc., to avoid broken damage and save occupancy space, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

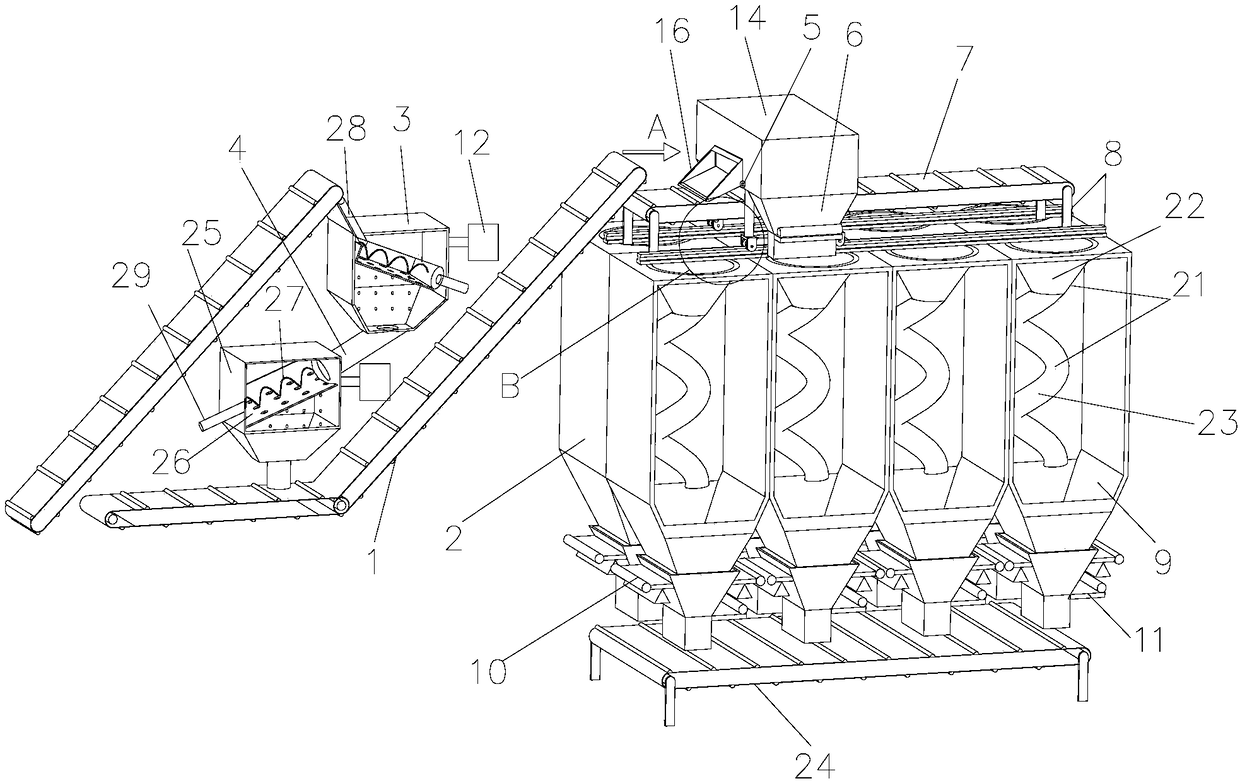

[0026] refer to figure 1 , figure 2 , the present embodiment includes a sequentially connected impurity removal device, a lifter 1, a classification binning device, and a grain storage bin 2, and also includes an automatic control device. The impurity removal device includes a multi-stage impurity remover 3, and the bottom of the impurity remover is Bucket-shaped, the discharge port of the upper-stage impurity remover is connected to the feed port of the next-stage impurity remover through the chute 4, and the bottom discharge port of the last-stage impurity remover is located above the lifter 1; the lifter 1 It is a belt hoist, the feed end of the belt hoist is located below the discharge port of the impurity removal device, and the discharge end of the belt hoist extends to the top of the sorting and warehousing device; the sorting and siloing device includes a horizontal conveyor belt 7, a positioning drop The material trolley 6, the positioning blanking trolley 6 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com