Horn pump

A horn and fluid technology, used in pumps, pumps with flexible working elements, liquid variable capacity machines, etc., can solve the problems of complex pump structure, monotonous form, lack of interest, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

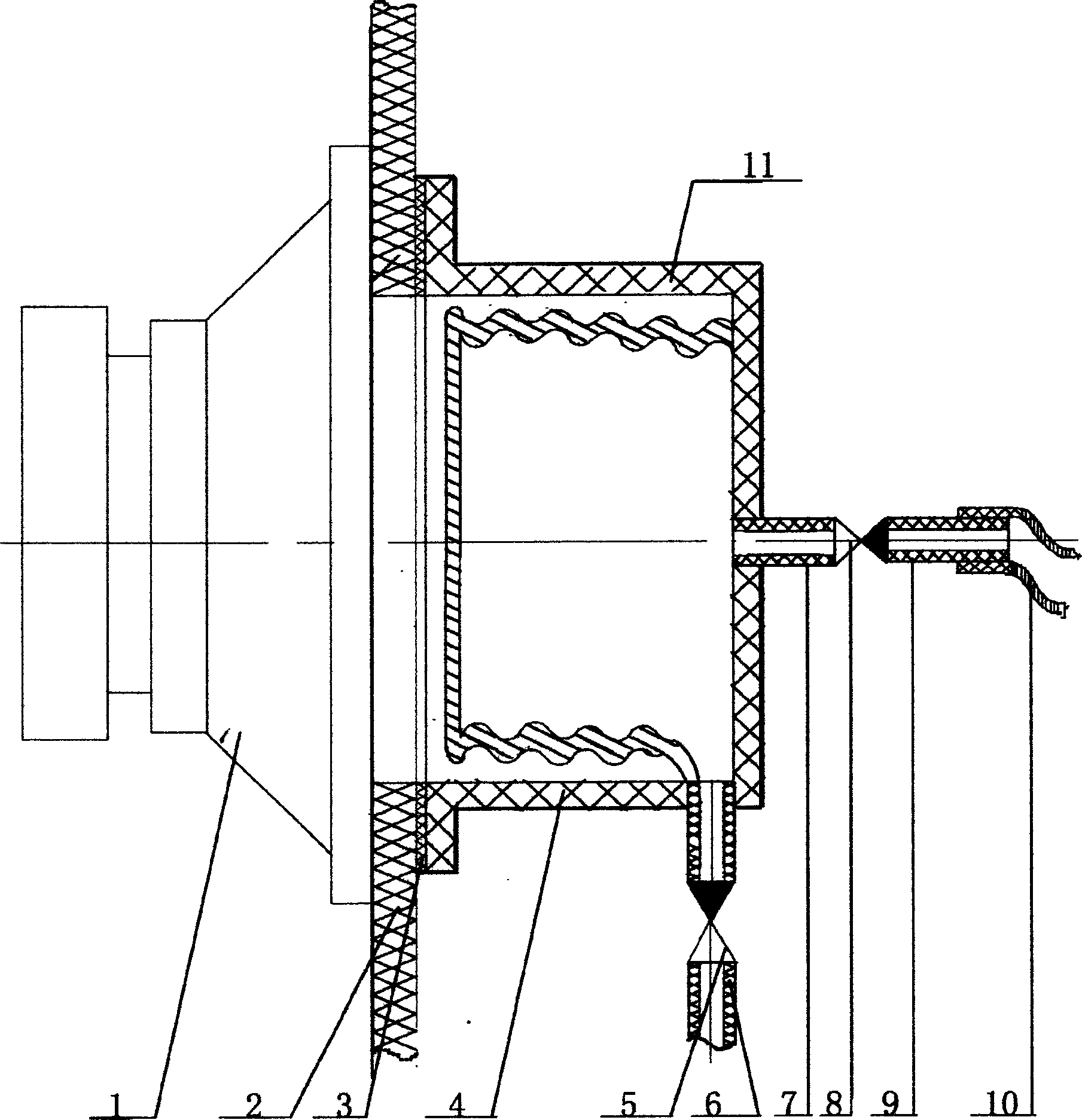

[0007] As can be seen from the accompanying drawings, the horn pump includes a horn 1, a speaker panel 2 for fixing the horn, and a fluid cover 4 is fixed on the speaker panel 2 at the outlet of the horn 1, and the cover 4 is provided with a fluid inlet and a fluid inlet for entering the fluid. The fluid outlet hole for going out, the fluid inlet hole is connected with the fluid inlet pipe 6, and the fluid inlet check valve 5 is connected on the inlet pipe 6, and the fluid inlet check valve is communicated with the inner chamber of the expandable liquid holding bag 11, and is connected with the bag. 11 The connected fluid outlet is connected with a fluid outlet pipe 7, and the fluid outlet pipe 7 is connected with an outlet check valve 8, and the cover 4 and the speaker panel 2 are sealed with a sealing gasket 3, and the outlet fluid check valve 8 can be installed There is a fluid pipe joint 9, and the fluid pipe joint 9 is connected with a fluid hose 10, and the fluid hose 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com