Gravel conveying belt

A conveyor belt and gravel technology, applied in the field of conveyor belts, can solve the problems of wasting construction conveyor belt materials, elongated production lines, splashing, etc., to reduce the workload of manual operations and inspections, reduce installation space, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

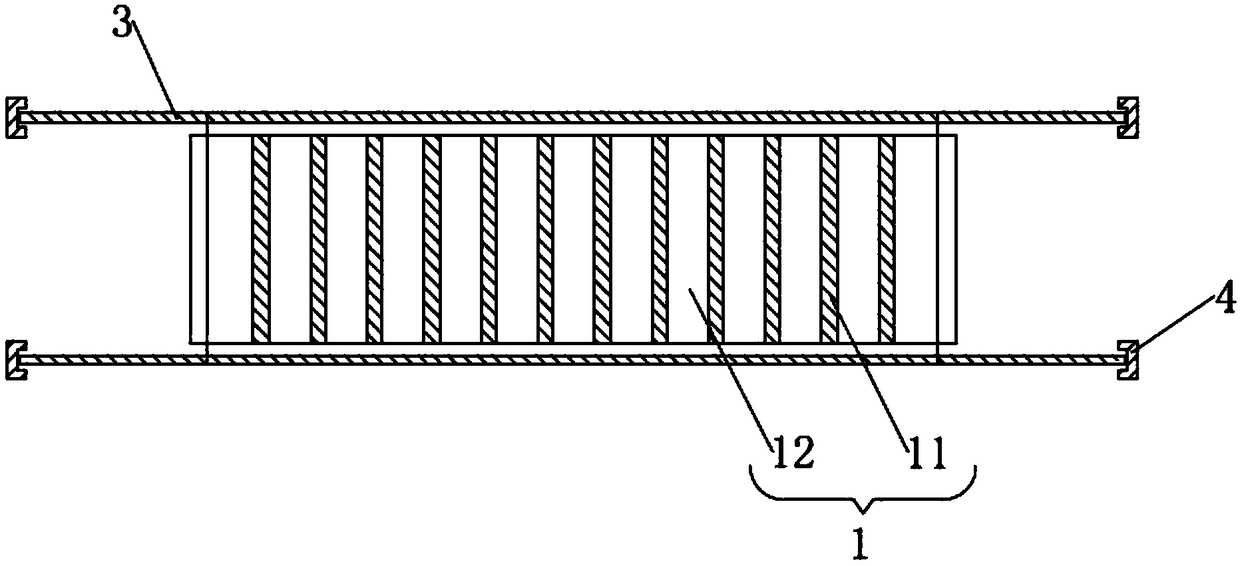

[0025] Embodiments of the present invention are as follows: Figure 1~3 As shown, a gravel conveyor belt includes a belt 1 and a roller 2. The edges on both sides in the extending direction of the belt 1 are closely attached to the rollers 2. The middle of the belt 1 is recessed downwards in the shape of a pocket, and the belt 1 is provided with multiple protrusions 11. , every two sections of protrusions 11 and the belt 1 form an accommodating cavity 12 for accommodating crushed stones. The present invention is used for gravel transportation in concrete processing. The protrusion 11 provided on the belt 1 is used to push the gravel forward along the moving direction of the belt 1, and can be transported from a high place to a low place or from a low place to a high place. Different from the conveyor belt provided in the prior art, it can only rely on friction to prevent gravel from falling, but cannot be set at an inclination of more than 45° with the ground, so it also takes...

Embodiment 2

[0029] In addition, the driving wheel 21 can be a conveying roller with narrow ends and a wide middle, which can further improve the effect of lifting the accommodation chamber 12, further increase the deformation of the accommodation chamber 12, and make the crushed stones in each accommodation chamber 12 be turned over Falls off belt 1.

[0030] When the present invention is in use, it is first necessary to set the position of the device and determine the direction of transport. Whether it is set up from top to bottom or from bottom to top, the device can be set to form an inclination angle of more than 70° with the ground, and will not Let the gravel roll and fall on belt 1. Then pour gravel into the belt 1 mechanically or manually, and the gravel will automatically enter the accommodation chamber 12 formed between the belt 1 and a plurality of protrusions 11, and after a housing chamber 12 is filled with gravel, the gravel will It will automatically roll down into the nex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com