Clamp transformation mechanism for large machine tool

A technology of converting mechanism and large machine tool, applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of waste of large machining centers, inability to clamp and fix, and achieve the effect of improving production efficiency and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

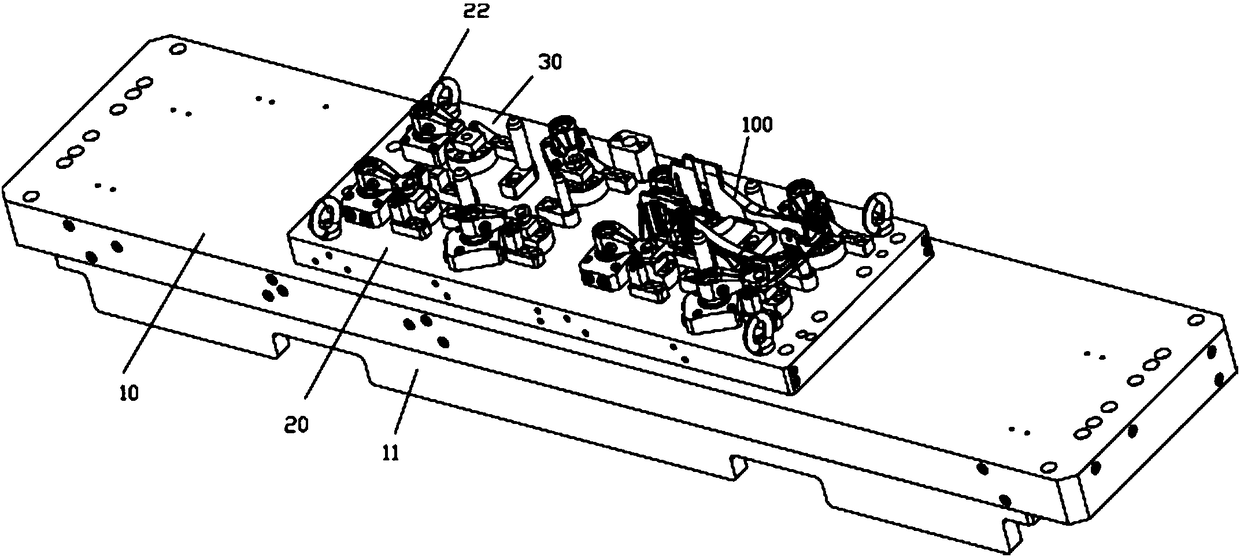

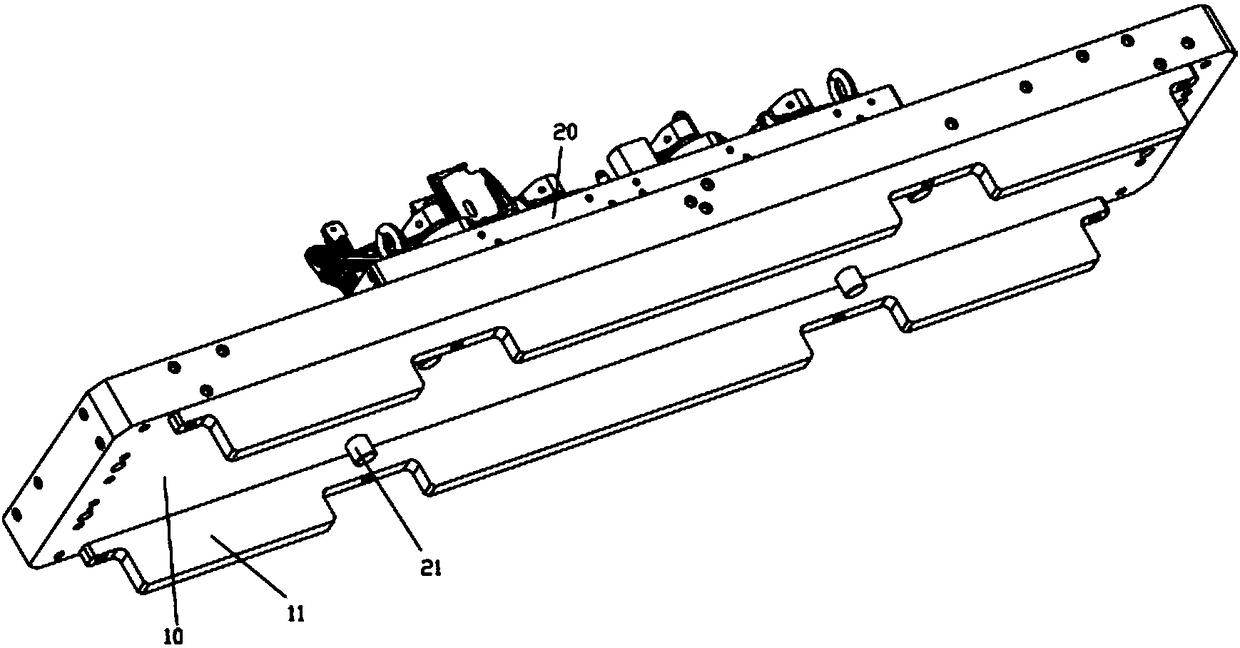

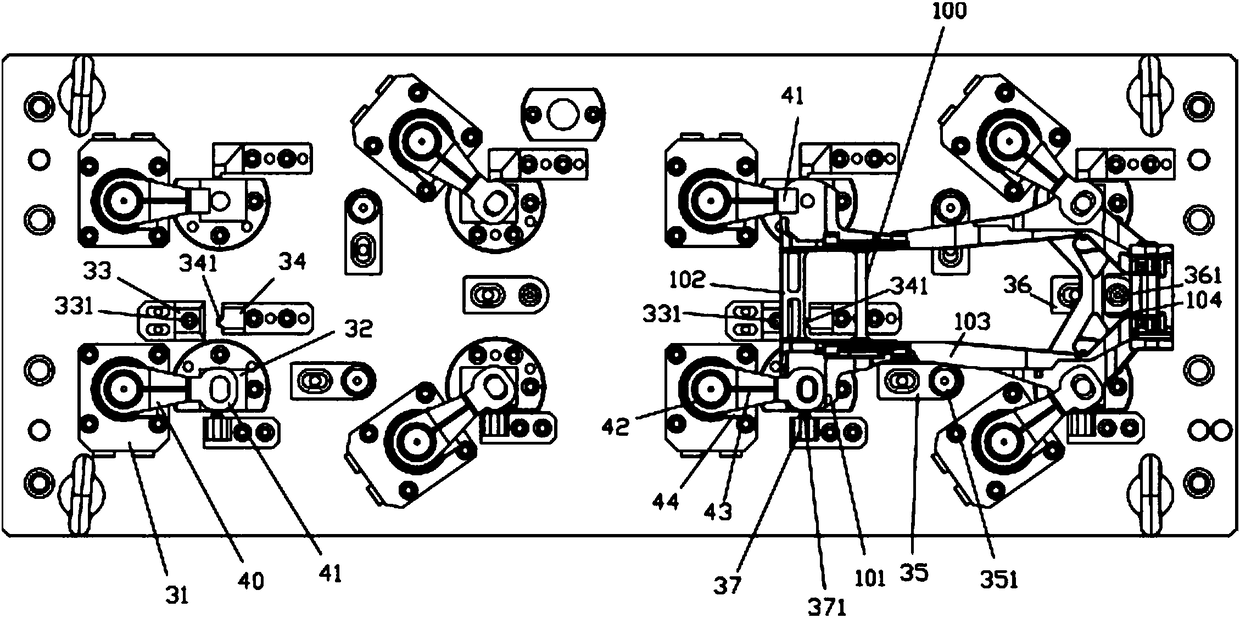

[0024] Examples, see e.g. Figure 1 to Figure 5 As shown, a clamp conversion mechanism for a large machine tool, which includes a fixed main aluminum plate 10, the middle top surface of the fixed main aluminum plate 10 is pressed against a bridge plate 20, and the front and rear parts of the left and right sides of the bottom surface of the bridge plate 20 are both A positioning column 21 is fixed, and the positioning column 21 is inserted into the positioning socket formed in the middle of the fixed main aluminum plate 10;

[0025] At least two sets of clamping mechanisms 30 are installed on the top surface of the bridge plate 20;

[0026] The clamping mechanism 30 includes a plurality of pressing and fixing cylinders 31, the upper part of the pressing and fixing cylinders 31 is fixed on the top surface of the bridge plate 20, and the cylinder body of the pressing and fixing cylinders 31 is inserted into the vertical passage of the bridge plate 20. In the hole, the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com