A taper screw tail removal device

A cone snail and vertical support technology, applied in slaughtering, food science, crustacean processing, etc., can solve the problems of poor quality of tailing, inability to remove tails neatly, difficulty in tailing, etc., achieve fast tailing and solve manual Difficult tail removal, good tail removal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

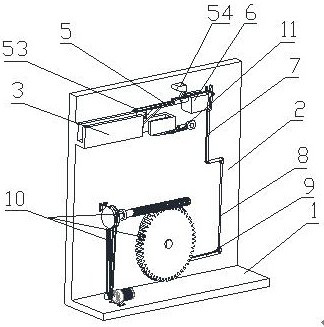

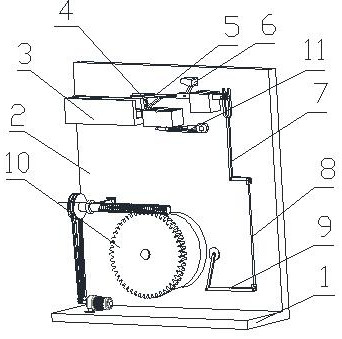

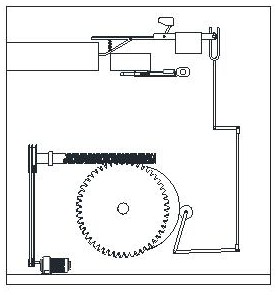

[0027] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0028] see Figure 1 to Figure 7 , the present invention is: a conical screw tailing device, comprising a base 1, a vertical support plate 2 arranged on the base 1, wherein, on the front side of the upper section of the vertical support plate 2, conical screw feeding Warehouse 3, cone screw fastening assembly 4, and cone screw clamping mechanism 5, cone screw clamping mechanism 5 reciprocates horizontally along the guide rail 6 fixed on the vertical support plate 2, and the cone screw clamping mechanism 5 The power drive end of the power drive is provided with a swinging part 7 to drive its operation. The swinging part 7 is movably connected to one end of the linkage rod 8, and the other end of the linkage rod 8 is hinged to the transmission structure 9; Mechanism 10 drive;

[0029] The cone screw tail removal device also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com