A preparation method and cleaning solution for an array substrate

An array substrate and cleaning solution technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of difficulty in removing copper-BTA, affecting the electrical properties of display devices, and affecting the stability of display devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

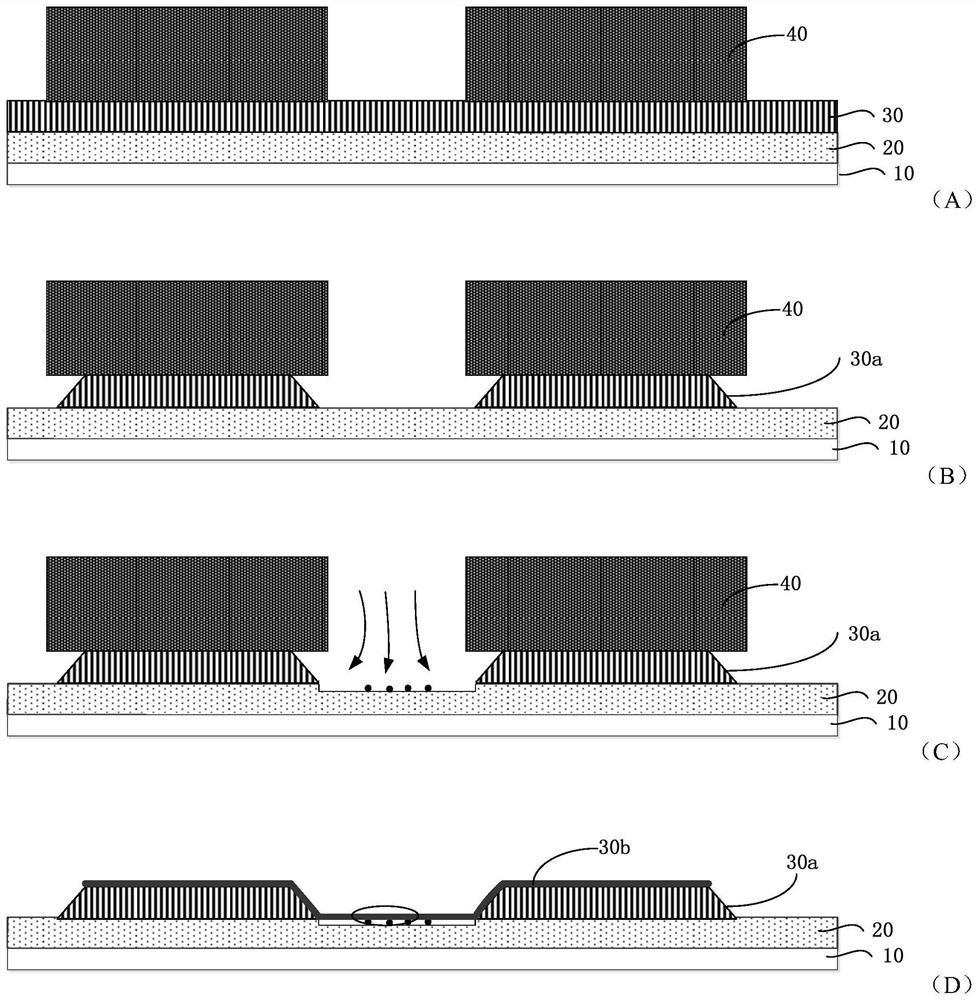

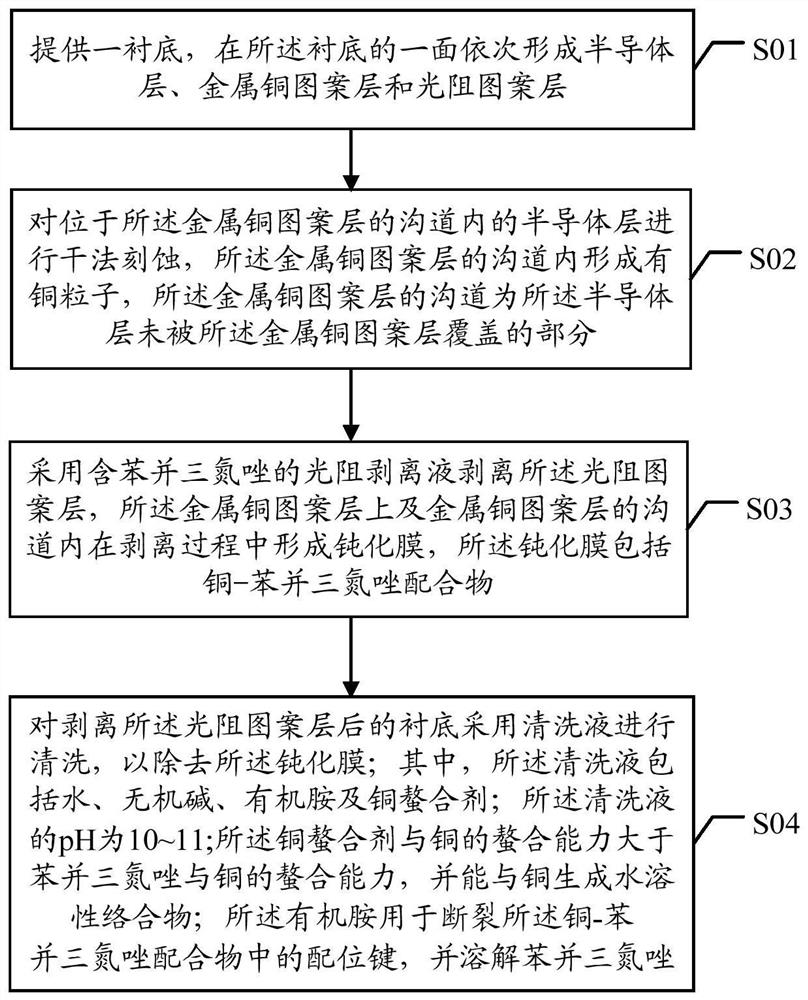

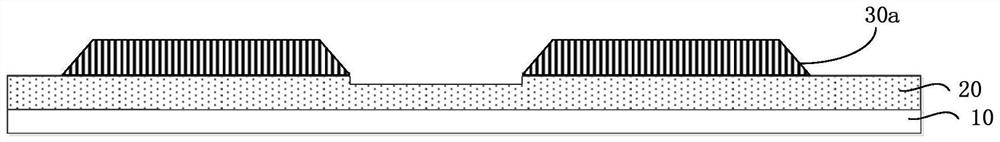

[0031] see figure 1 , figure 1 It is a schematic structural diagram of the array substrate before and after stripping with a photoresist stripping solution in the copper manufacturing process in the prior art. figure 1 Middle (B) to figure 1 The photoresist pattern layer 40 in (A) is a mask, and the initial copper film 30 has been etched (for example, using H 2 o 2 After performing wet etching), a metal copper pattern layer 30 is obtained, which may specifically be a source electrode and a drain electrode. figure 1 Middle (C) is right figure 1 In (B) the semiconductor layer 20 in the channel of the substrate is dry-etched to thin the semiconductor layer 20, leaving only the regions that can be in contact with the source and drain, which can be called the source contact region and the drain respectively. pole contact area. However, it should be noted that when the semiconductor layer 20 is dry etched, the etching gas used in the dry etching will bombard the metal copper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com