Circumferential prestressing concrete pouring jacket used for foundation construction of bearing platform and manufacturing and installing method thereof

A technology of foundation construction and production method, which is applied in the direction of foundation structure engineering and construction, can solve problems such as casing cracking, and achieve the effect of convenient installation, saving time for demolition and post-repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

[0040] This example provides a hoop prestressed concrete box based on the characteristics of the multi-pile cap foundation, thereby improving the integrity of the box, and solving the expansion and boxing of the existing cast-in-place concrete under the action of hydration heat. The box cracking problem caused by the temperature difference inside and outside itself.

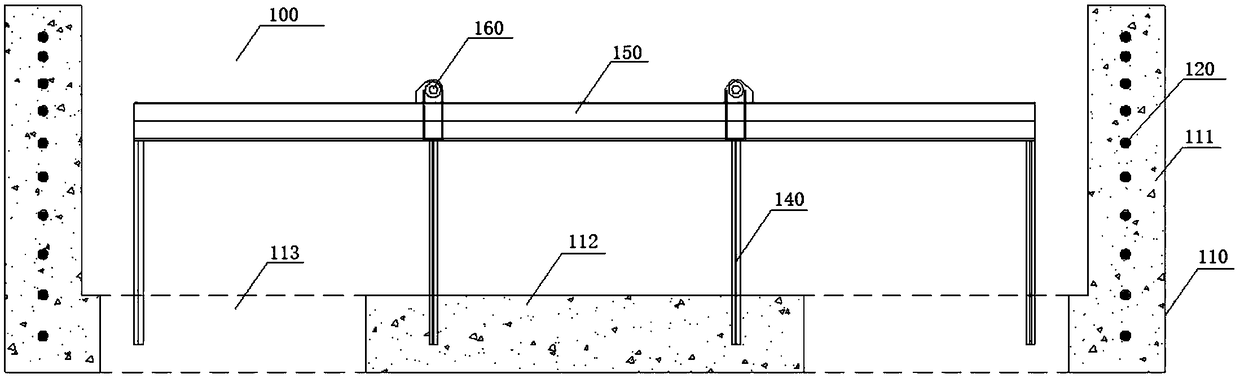

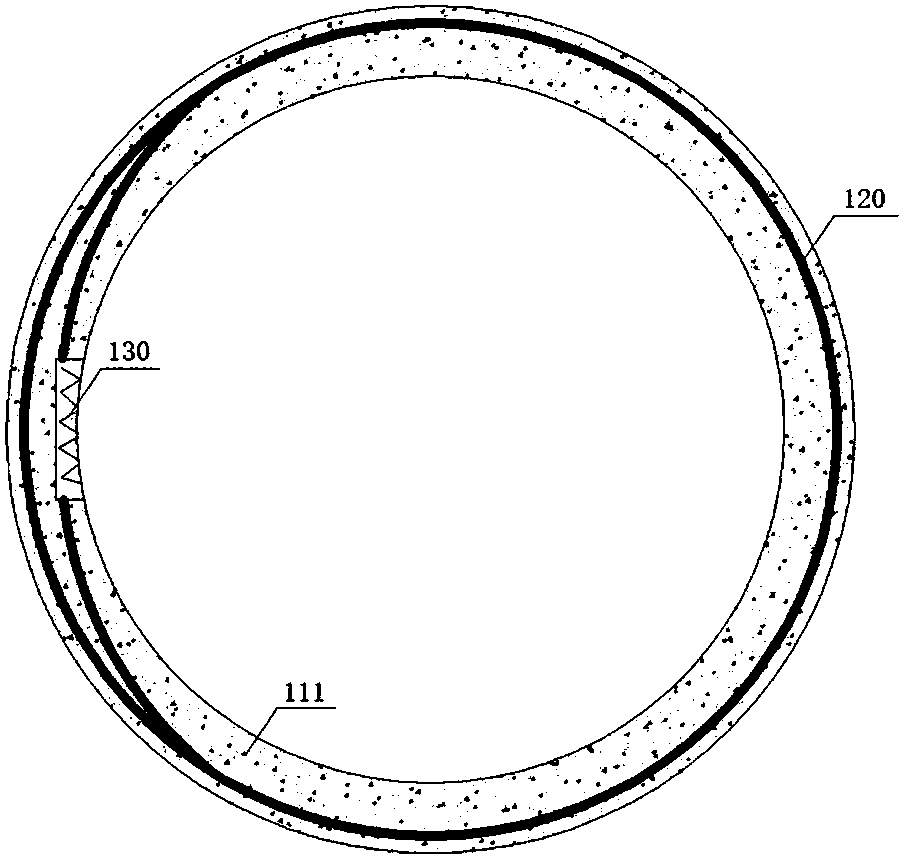

[0041] See figure 1 , Which shows an example structure of the hoop prestressed concrete box given in this example. It can be seen from the figure that the hoop prestressed concrete box 100 mainly includes a concrete box body 110. The concrete box body 110 is cylindrical as a whole and has a U-shaped cross section.

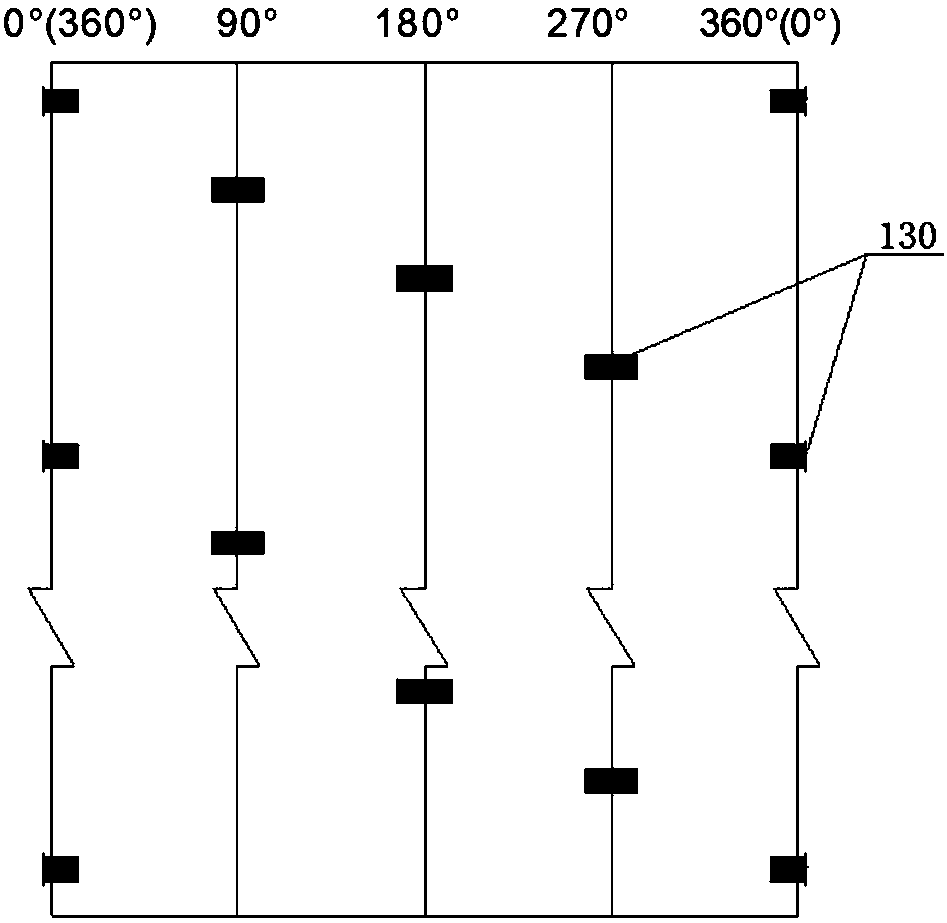

[0042] Several layers of circumferential prestressing tendons 120 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com