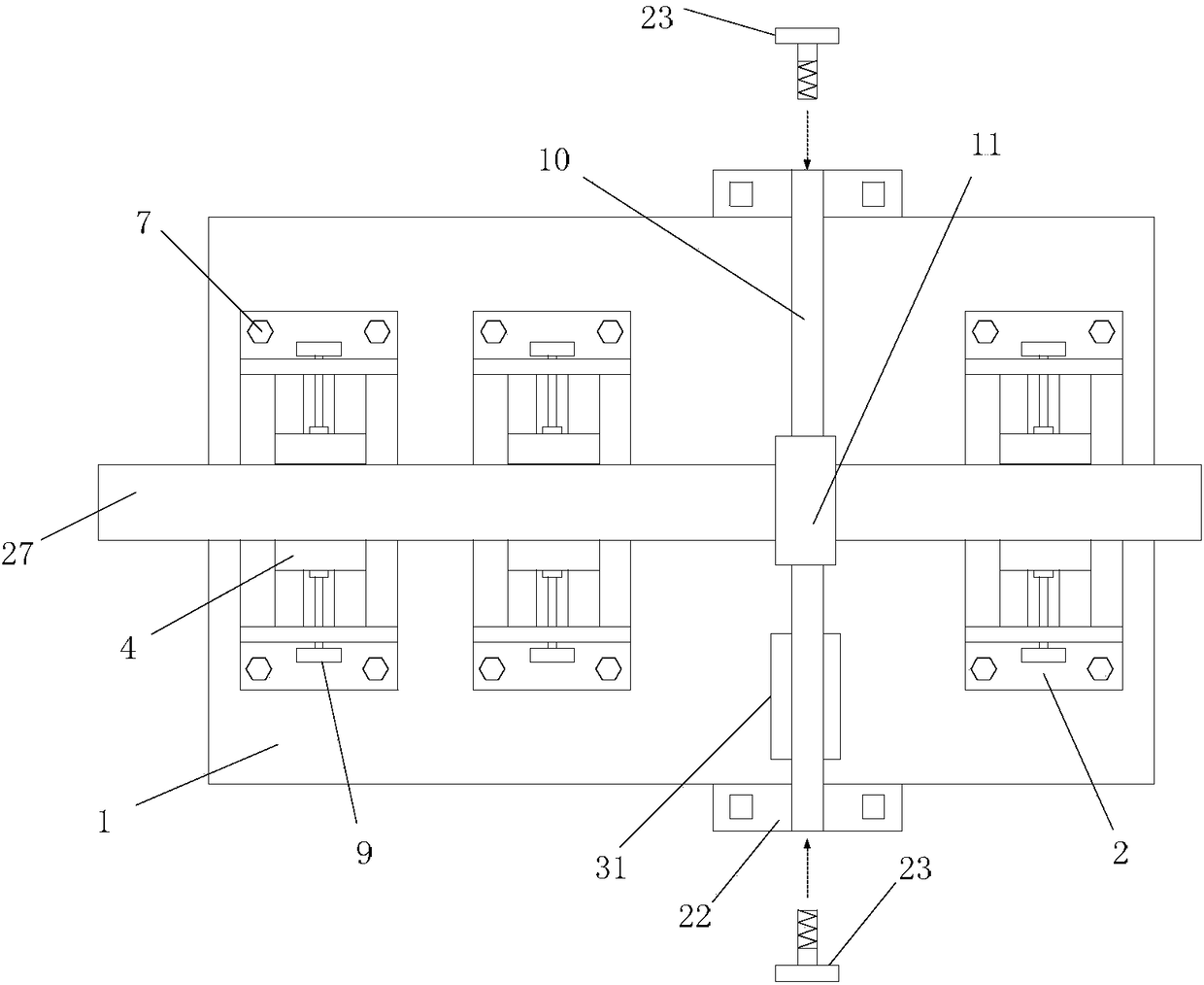

Novel plastic profile cutting equipment

A technology for plastic profiles and cutting equipment, used in metal processing and other directions, can solve the problems of poor safety, low precision, and low product quality, and achieve the effect of reducing the probability of misoperation and injury and facilitating accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Follow the steps below to complete the cutting operation

[0043] First, install the fixture base 2 on the machine platform 1, and tighten the screw 7; set the cutting angle, for cutting in a 90-degree direction, insert the interlocking column 20 into the vertical limit hole 25, and for cutting in a 45-degree direction, insert the The embedding column 20 is inserted into the oblique limiting hole 26 , and the fastening stud 23 is inserted into the fixing hole 24 and the embedding hole 21 and tightened to fasten the embedding column 20 on the machine platform 1 .

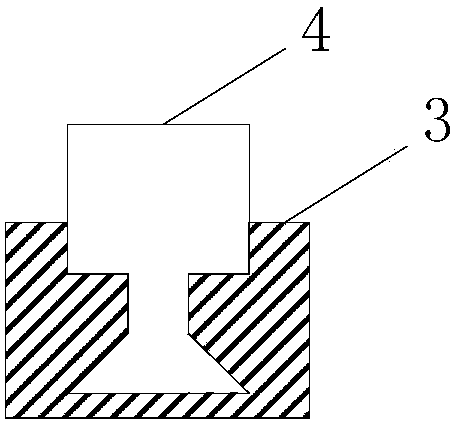

[0044] Second, according to the requirements, mark the position to be cut on the plastic profile 27 in advance, place the mark between the two clamping parts 4 of the fixture, turn on the laser emitter 29, push the plastic profile 27 back and forth, so that the mark of the cutting position falls on the On the light spot of the laser transmitter 29, after the location is selected, the knob 9 on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com