Device for aligning stopper rod precisely and aligning process for intermediate stopper rod

A precise alignment and tundish technology, which is applied in the direction of manufacturing tools, metal processing equipment, casting melt containers, etc., can solve the problems of lax closing, high labor intensity, inaccurate stroke control, etc., and prevent the fluctuation range from being too large , Convenient stopper rod installation, accurate displacement stroke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

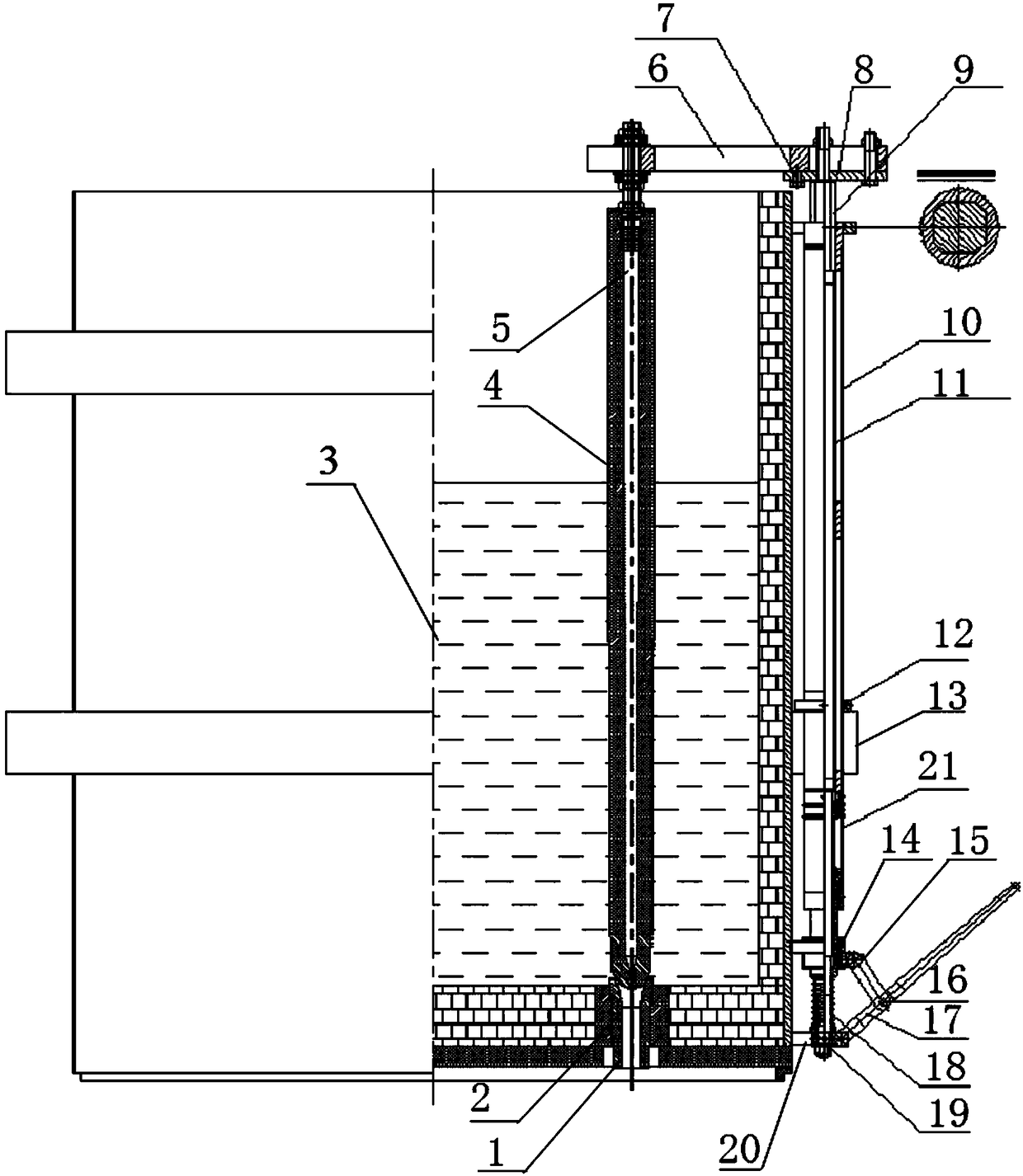

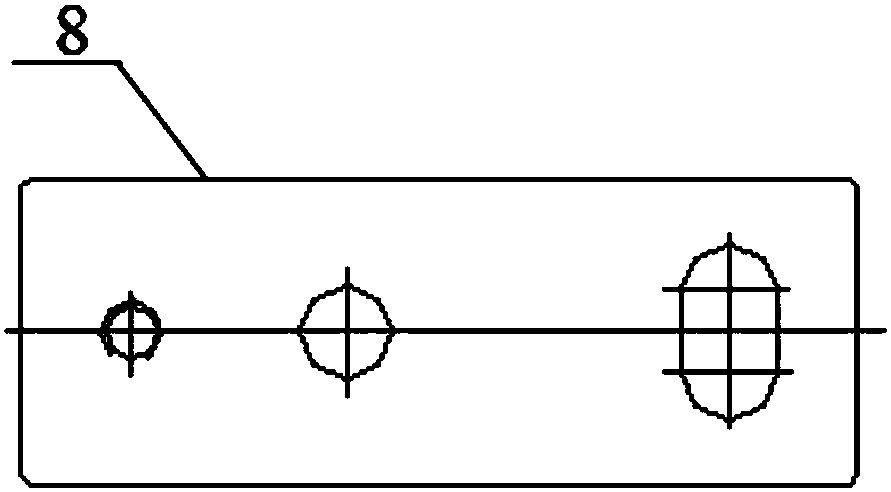

[0024] The present invention provides a device for precisely aligning stopper rods, referring to figure 1 and figure 2 , including a vertical stopper rod 4, the stopper rod 4 is hollow, the bottom of the stopper rod 4 is provided with a stopper head 2 for sealing the nozzle brick 1 in the ladle, and the adjusting core rod 5 is fixed to the stopper rod through the threaded hole on the top of the stopper rod Among them, the top of the adjusting core rod 5 is fixed on one end of the crossbeam 6, and the other end of the crossbeam 6 is fixed on the upper surface of the transverse support plate 8 through the angle adjustment bolt 7, and the support plate 8 is provided with a waist hole for guiding the positioning rod 9 to pass through. The top of the guide positioning rod 9 passes through the waist hole of the support plate 8 and is fixedly connected with the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com