Ultrasonic cleaning machine for cleaning residues left after laser engraving of plastic casing of mobile phone

An ultrasonic and cleaning machine technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as uneven sound pressure intensity, achieve uniform ultrasonic sound pressure distribution, and easy control of solution temperature. , good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

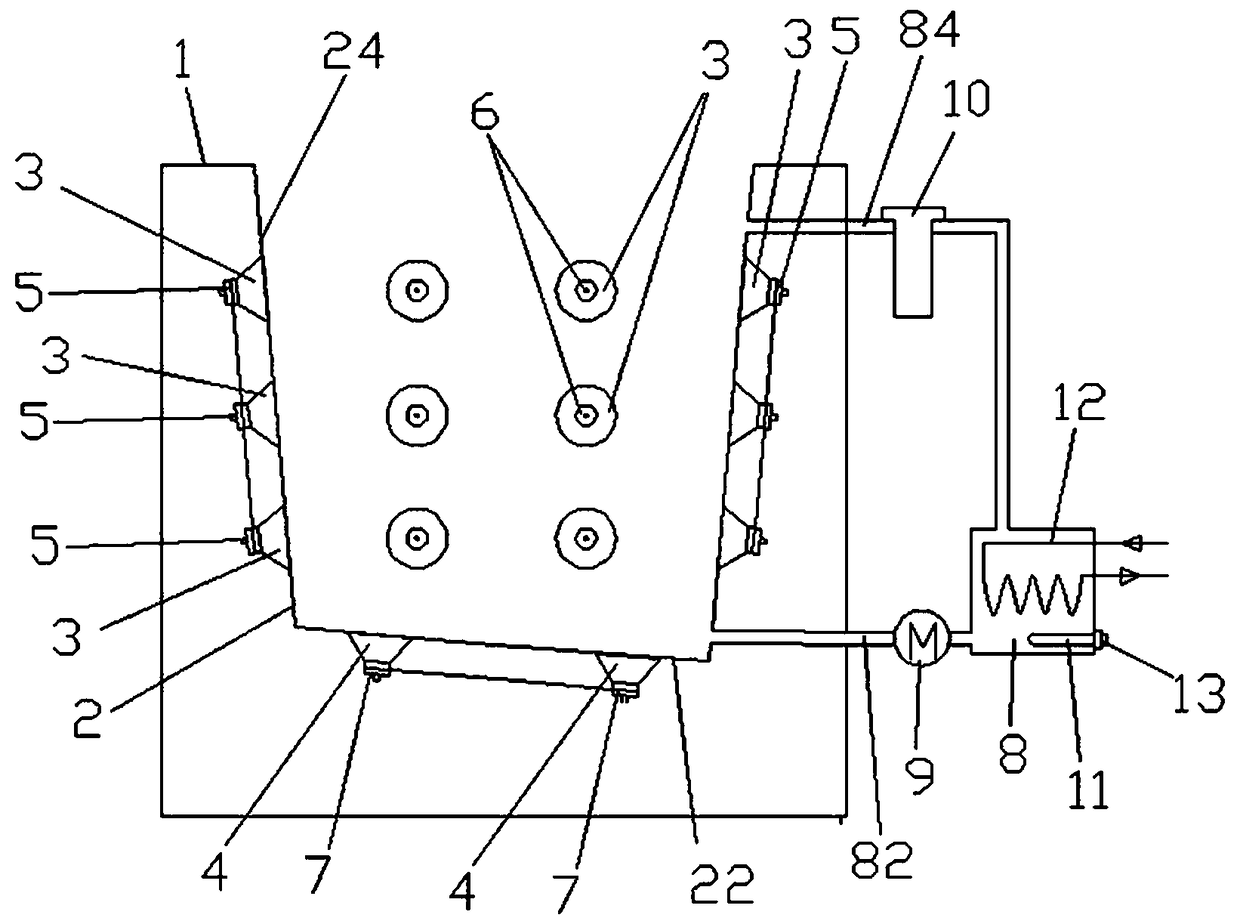

[0026] see figure 1 , an ultrasonic cleaning machine for cleaning residues left after laser engraving on plastic casings of mobile phones, which includes a cleaning machine casing 1, a cleaning tank 2, side piezoelectric transducers 3, bottom piezoelectric transducers 4, left and right Direction ultrasonic generator 5, front and rear direction ultrasonic generator 6, up and down direction ultrasonic generator 7, liquid storage tank 8, circulation pump 9, filter 10, heating pipe 11, condensation pipe 12, temperature controller 13.

[0027] Washing machine casing 1 is placed on the ground.

[0028] The cleaning tank 2 is installed and fixed in the cleaning machine casing 1.

[0029] The cleaning tank 2 includes a bottom plate 22 and four side plates 24 .

[0030] The bottom plate 22 is quadrangular.

[0031] The bottom plate 22 is not parallel to the horizontal plane, but is inclined as a whole.

[0032] Four side panels 24 extend upward from four edges of the bottom panel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com