Airplane environment control and fuel tank inerting coupled system and method based on membrane separation method

一种膜分离法、耦合系统的技术,应用在分离方法、化学仪器和方法、飞机零件等方向,能够解决部件多、重量大、结构复杂等问题,达到系统结构简单、制冷量大、提升性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The aircraft environment control and fuel tank inerting coupling system based on the membrane separation method according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings. But the scope of protection of the present invention is not limited to the following examples.

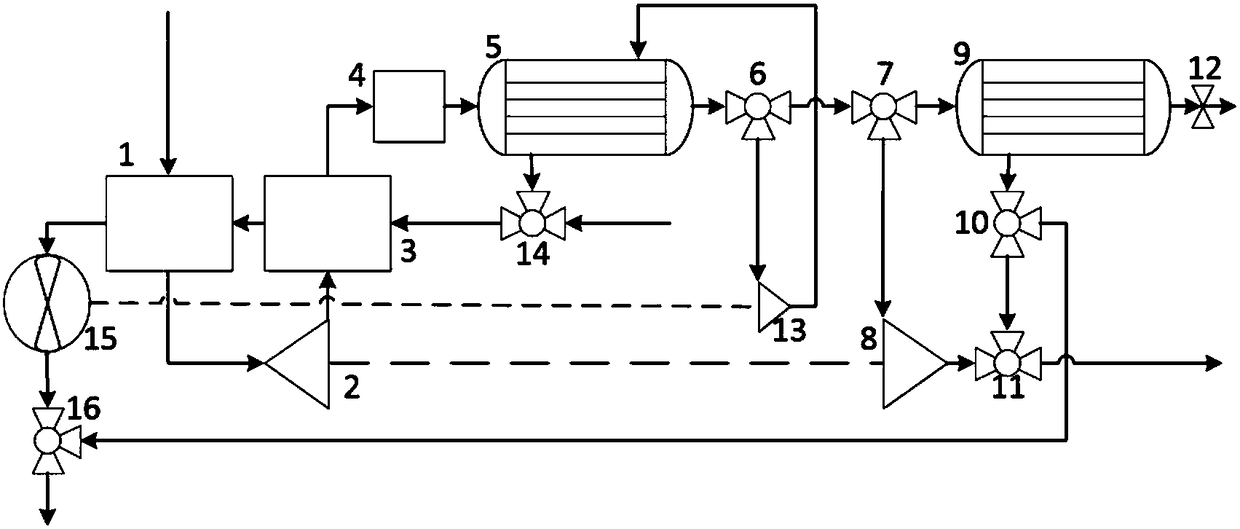

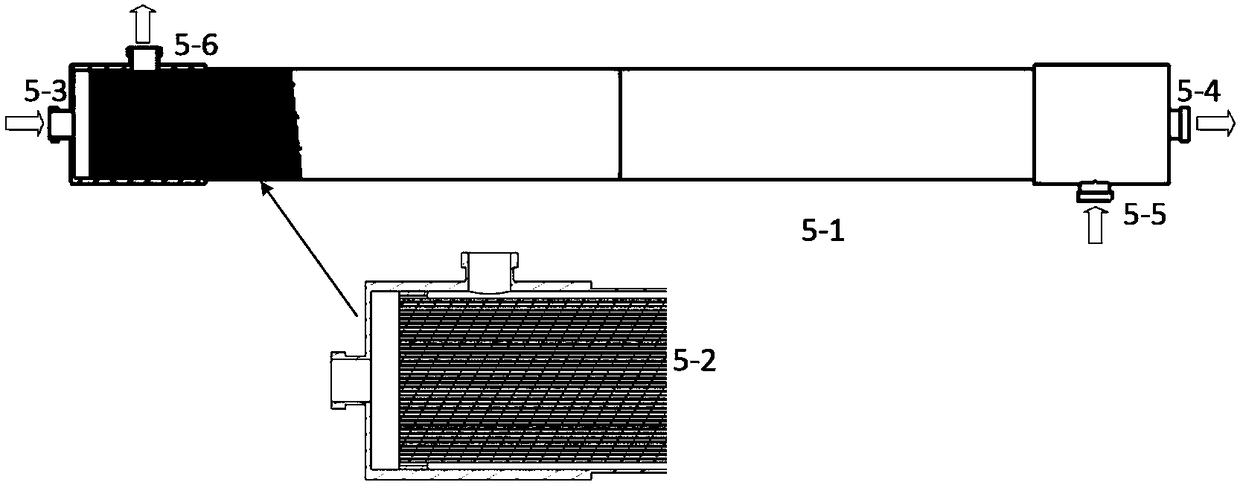

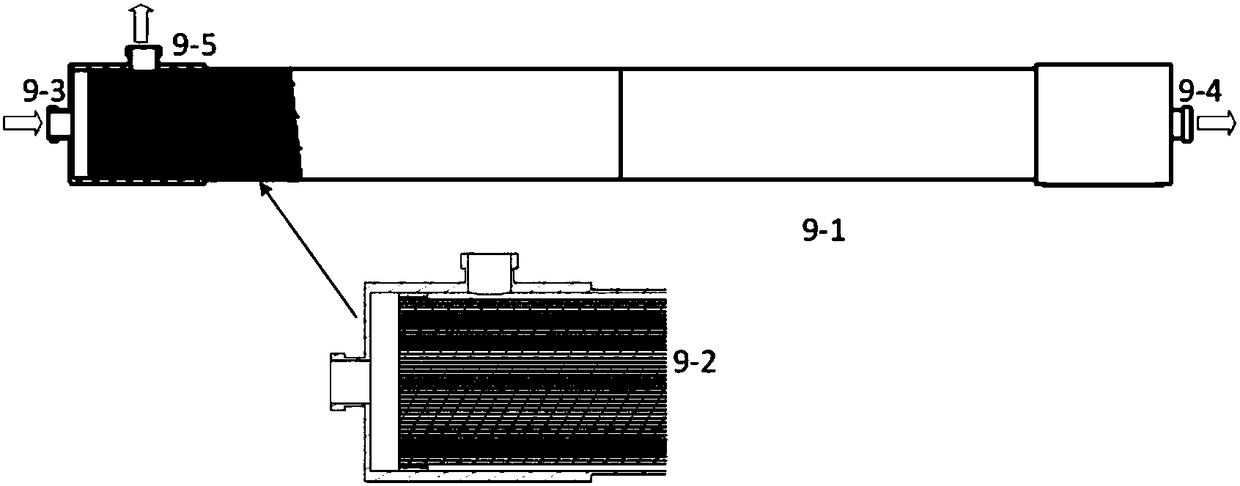

[0063] Such as figure 1 The shown aircraft environment control and fuel tank inert coupling system based on the membrane separation method according to an embodiment of the present invention includes: primary heat exchanger (1), supercharger (2), secondary heat exchanger (3) , filter (4), membrane dehumidification heat exchanger (5), first three-way valve (6), second three-way valve (7), large expansion turbine (8), membrane air separator (9), the first Three three-way valve (10), fourth three-way valve (11), flow limiting valve (12), small expansion turbine (13), fifth three-way valve (14), fan (15), sixth three-way valve (16). Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com