Steam energy cascade heat recovery utilization system for operation under full working conditions and working method

A full working condition, steam technology, applied in the direction of steam application, heating system, machine operation mode, etc., can solve the problems of low operating hours, affecting the economic benefits of the system, and not fully exploiting the potential, so as to reduce coal consumption and plant The effect of improving the power consumption rate, realizing the utilization of cascade heat recovery, and increasing the number of operating hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

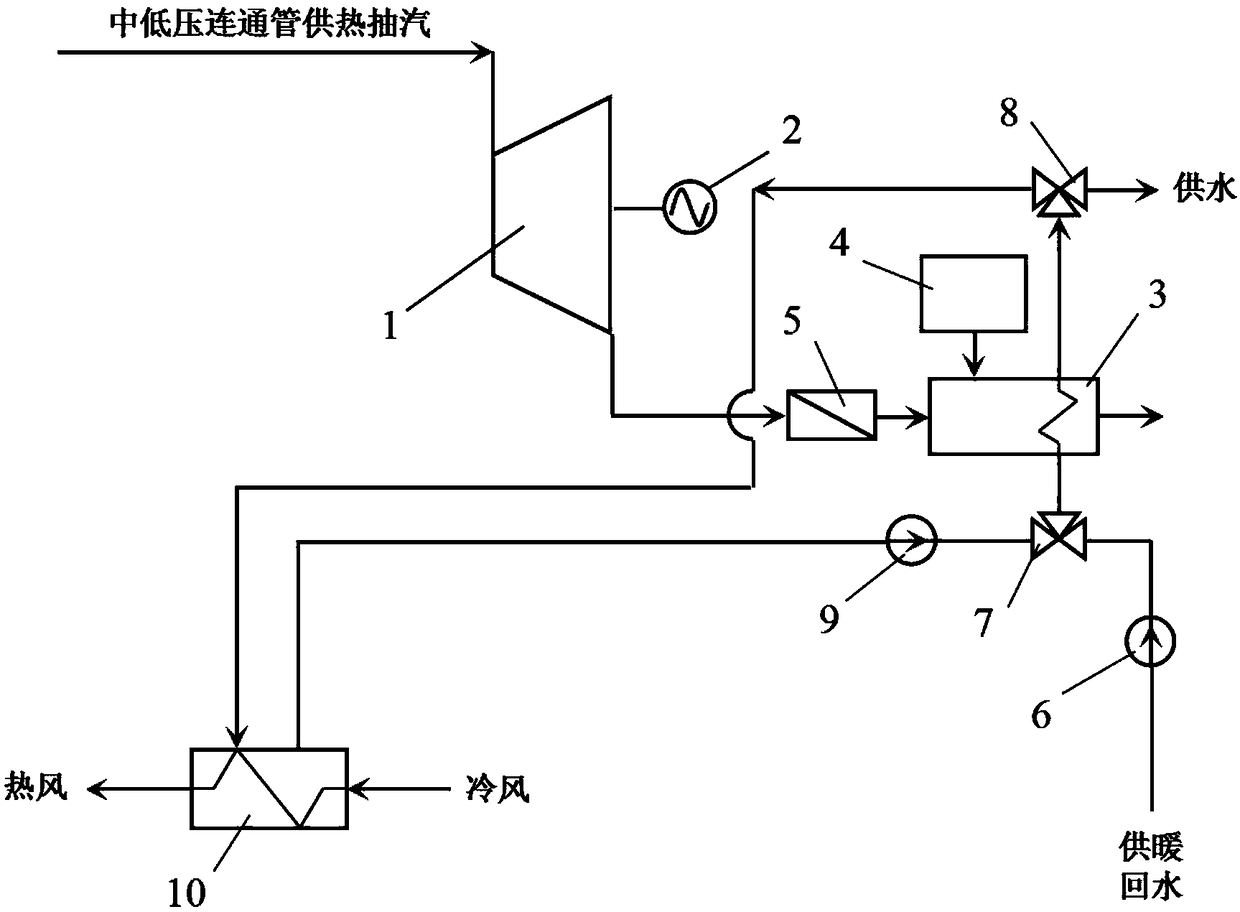

[0018] like figure 1 As shown, this embodiment is a steam energy cascade heat recovery utilization system operating under all working conditions. The steam extracted from the medium and low pressure connecting pipe of the thermal power unit enters the back pressure steam turbine 1 to recover high-grade energy, and drives the generator to generate electricity through the coupling, and the generated energy is directly incorporated into the power system of the power plant. The exhaust steam from the back pressure steam turbine 1 is adjusted by the desuperheater 5 to meet the driving steam parameter requirements of the absorption heat pump 3, and then enters the absorption heat pump 3, and drives the absorption heat pump 3 to recover the heat of the low-grade heat source 4 for external supply. hot. During the heating season, the heat supplied by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com